Waterborne epoxy ester resin composition and preparation method thereof and water-based paint prepared from same

A technology of epoxy ester resin and composition, applied in the direction of epoxy resin coating, coating, etc., can solve the problems such as excellent water resistance and corrosion resistance of coating film, damage of resin coating film, slow strength of paint film, etc. Improve anti-corrosion and water resistance, excellent anti-corrosion and water resistance, and avoid early damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

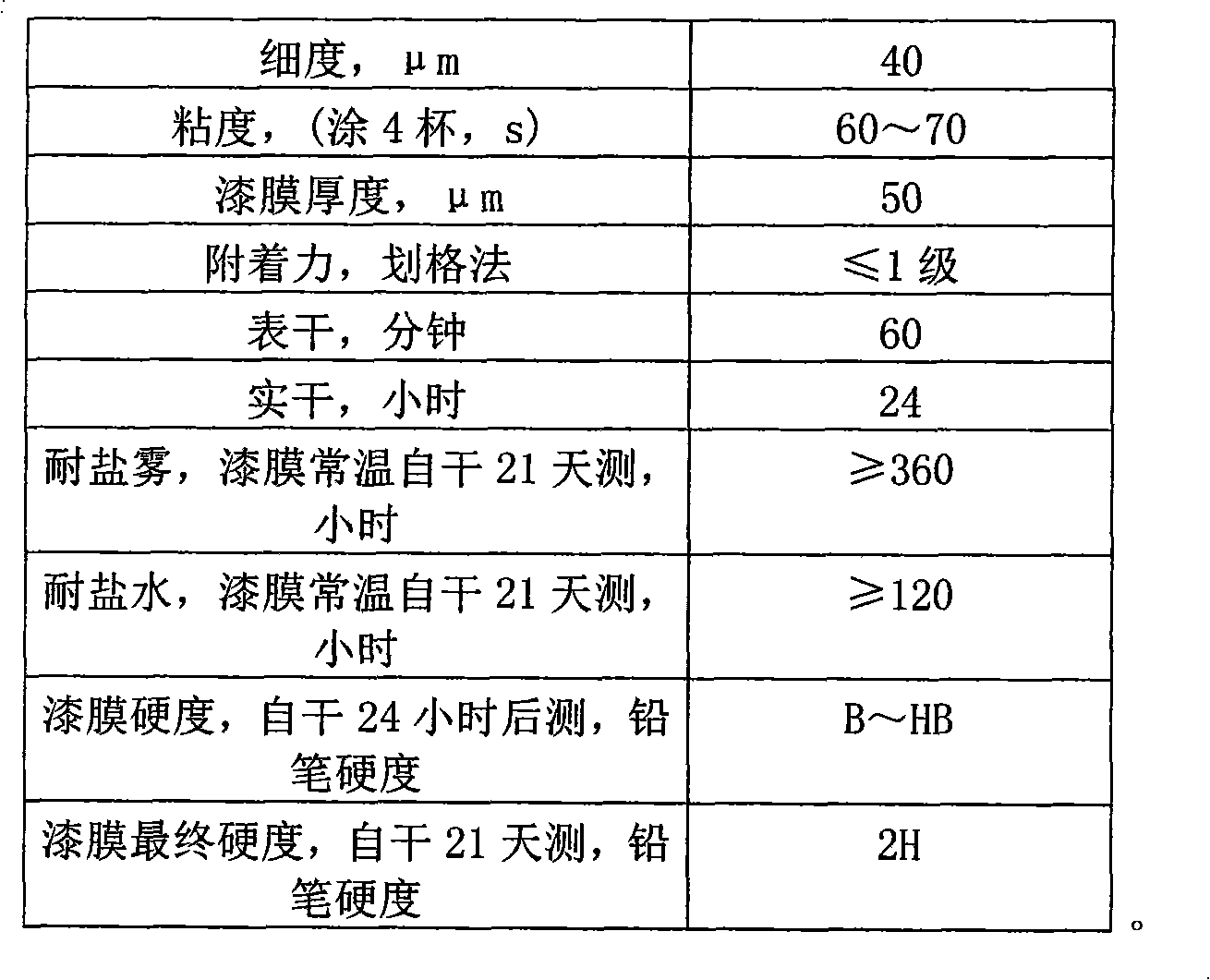

Examples

preparation example Construction

[0039] The present inventors found that by changing the preparation process of water-based epoxy ester, a water-based epoxy ester resin composition with stable storage and low solid acid value can be prepared. The preparation process of waterborne epoxy ester is changed to: (1) Vinyl monomer free radical solution polymerization prepares carboxyl-containing water-dispersible vinyl resin (a), its solid acid value is 50-250 mg KOH / g, molecular weight 3000 ~6000. (2) Epoxy resin and fatty acid carry out epoxy ring-opening reaction and prepare epoxy ester resin (b), wherein epoxy resin is excessive 10~100% than fatty acid, make residual a certain amount of epoxy groups on the gained epoxy ester resin group. (3) Add the carboxyl vinyl resin (a) prepared in step (1) into the epoxy ester resin (b), so that the carboxyl group contained in the vinyl resin is the same as the reserved epoxy group on the epoxy ester reaction to obtain a vinyl-modified epoxy ester resin (A). (4) adding a...

Embodiment 1

[0060] This embodiment is intended to demonstrate the preparation method of waterborne epoxy ester resin composition, as follows:

[0061] (1) Add 400g propylene glycol butyl ether into the reaction vessel and stir to heat up; add 100g styrene, 100g methyl methacrylate, 120g butyl acrylate, 60g methacrylic acid, 60g acrylic acid, 5g divinylbenzene, 5gN-isobutyl Oxymethacrylamide and 15g of benzoyl peroxide are mixed and dissolved to make a monomer drop feed, and the monomer drop feed is added dropwise to the reaction vessel when the temperature of the reaction vessel rises to 120-130°C. Keep the reaction temperature at 120-130°C, and add the monomer dropwise for 4-5 hours. After monomer addition, keep warm at 120-130°C for 2 hours, and add 3 g of benzoyl peroxide per hour. After the heat preservation is completed, the temperature is lowered to 60°C and the material is discharged. The weight solid content of the obtained vinyl resin (a) solution is 53%, the acid value of the ...

Embodiment 2

[0068] This embodiment demonstrates the use of different grades of epoxy resins to prepare water-based vinyl modified epoxy ester resin compositions, as follows:

[0069] (1) Add 200g propylene glycol ether into the reaction vessel and stir to heat up; add 100g styrene, 100g methyl methacrylate, 100g butyl acrylate, 30g methacrylic acid, 30g maleic anhydride, 5g ethylene glycol diacrylate, 5g Glycidyl methacrylate and 15 g of benzoyl peroxide are mixed and dissolved to make monomer drop feed, and the monomer drop feed is added dropwise to the reaction vessel when the temperature of the reaction vessel rises to 120-130°C. Keep the reaction temperature at 120-130°C, and add the monomer dropwise for 4-5 hours. After monomer addition, keep warm at 120-130°C for 2 hours, and add 3 g of benzoyl peroxide per hour. After the heat preservation is completed, the temperature is lowered to 60°C and the material is discharged. The weight solid content of the obtained vinyl resin (a) solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com