Battery charging and discharging management system

A charging and discharging management, battery technology, applied in battery circuit devices, charge equalization circuits, arrangement of multiple synchronous batteries, etc., can solve problems such as casing deformation, battery life decay, positive grid bending and fracture, etc., to avoid Deep discharge, prolonging the effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

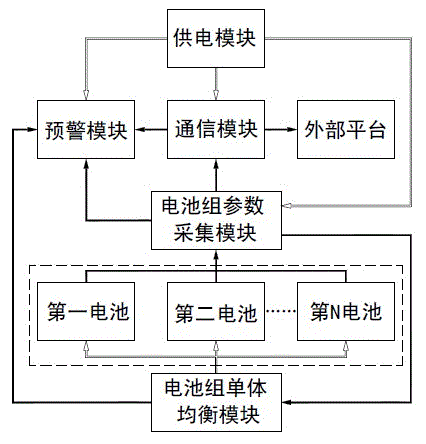

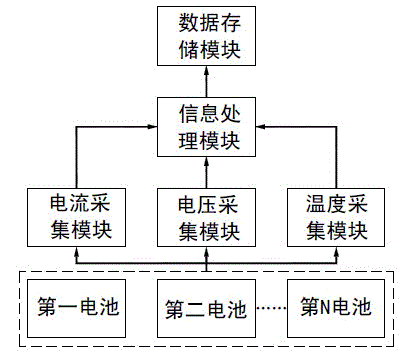

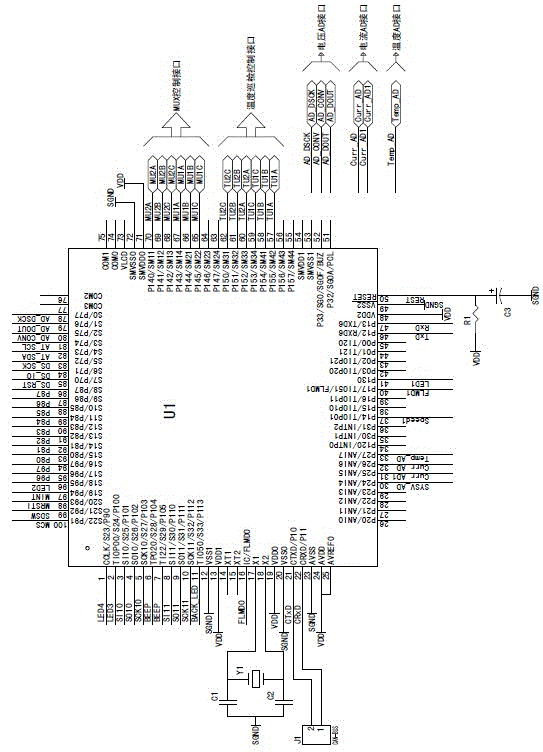

[0035] Figure 1~9 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~9 The present invention will be further described.

[0036] in such as figure 1 In the principle box shown, the black arrow indicates the direction of the signal source, and the white arrow indicates the direction of the power signal. Battery charge and discharge management system, including power supply module, early warning module, communication module, battery pack parameter acquisition module, battery pack and battery pack monomer equalization module, the battery pack includes the first battery, the second battery...the Nth battery, etc. save battery. The power supply module is simultaneously connected with the early warning module, the communication module and the battery pack parameter acquisition module to provide power for them. The battery pack monomer balancing module is connected to all the batteries in the battery pack at the same time, and realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com