Full steel radial brand-new tire with heavy duty tire bead structure

A radial and bead technology, applied in tire parts, reinforcement layers of pneumatic tires, tire edges, etc., can solve the problems of tire ring empty, stress concentration, large deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

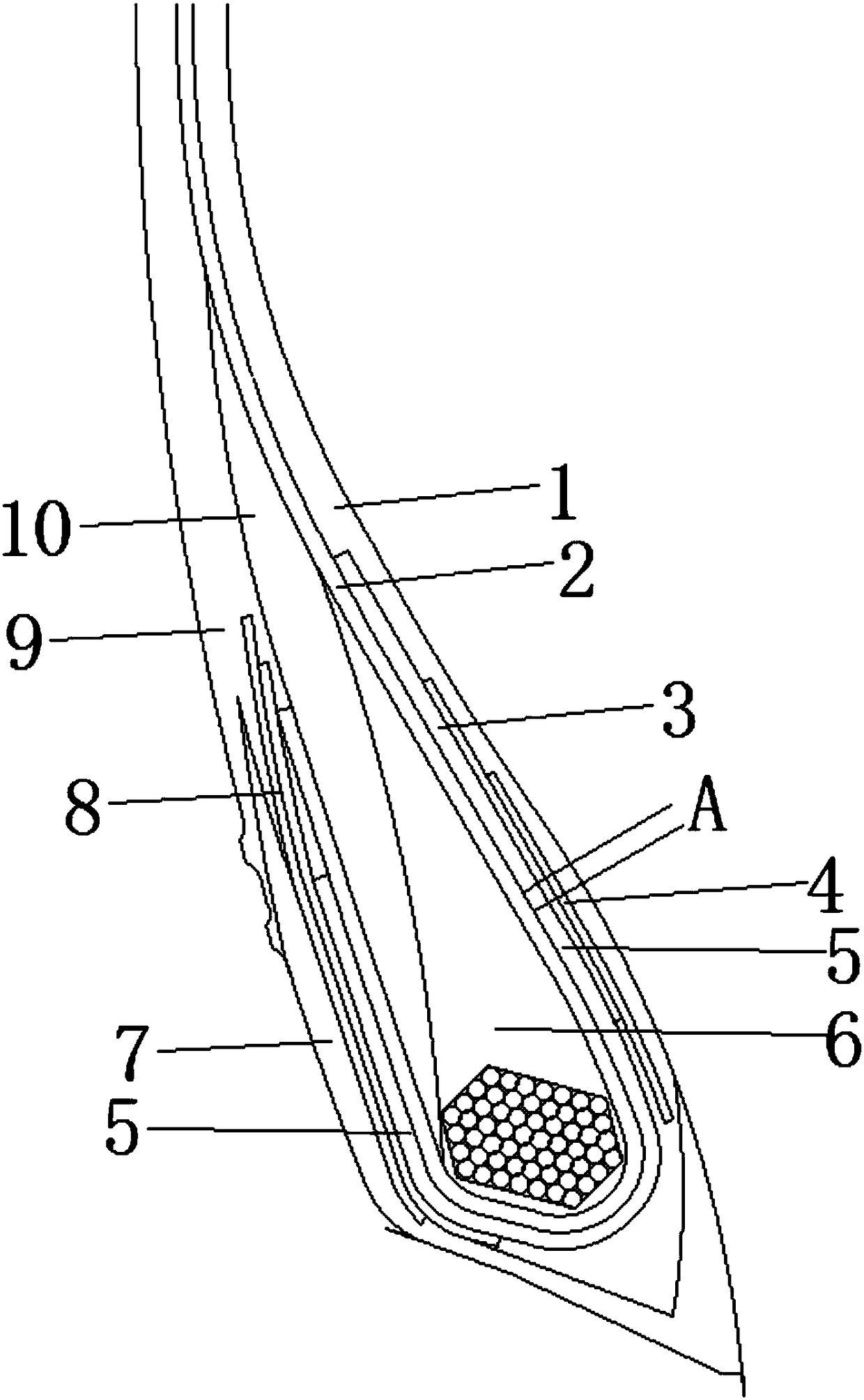

[0015] Such as figure 1 As shown, the new all-steel radial tire with heavy-duty bead structure includes a bead structure. The bead structure includes an apex rubber core, and the outside of the rubber core is wrapped with a carcass cord 2. The outer part of the azimuth is wrapped with the outer bead reinforcement cord 5, the surface of the carcass cord 2 located at the inner side of the bead structure is provided with the inner bead reinforcement cord 3, and the inner part of the bead structure is also provided with a reinforcement covering the outer bead. Cord 5 and inner fiber cord 4 on the outside of inner mouth reinforcement cord 3, bead structure end surface orientation and bead structure inner orientation are also provided with covering outer mouth opening reinforcement cord 5, inner mouth opening reinforcement cord 3, inner fiber cord 4 and carcass The inner lining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com