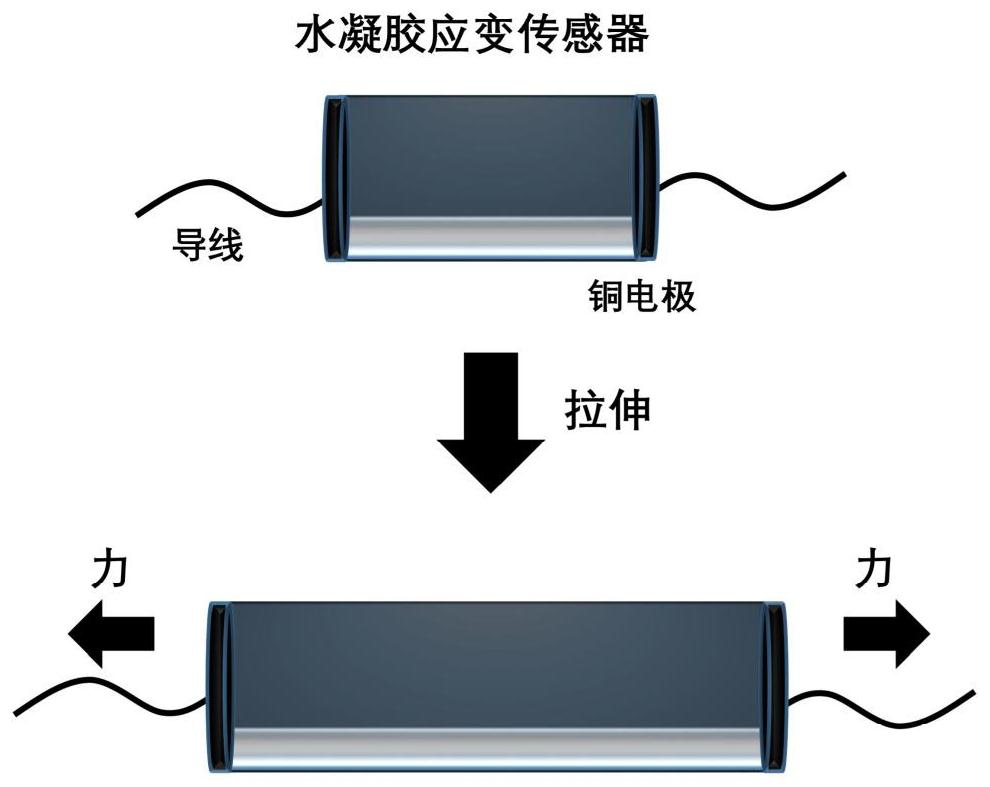

Gallium/sodium alginate/polyacrylamide composite hydrogel material as well as preparation method and application thereof

A polyacrylamide and composite hydrogel technology, which is applied in the application field of flexible strain sensors, can solve the problems of poor fit and low tensile properties of hydrogels, and achieves improved toughness and recoverability, high toughness, Effective stress dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

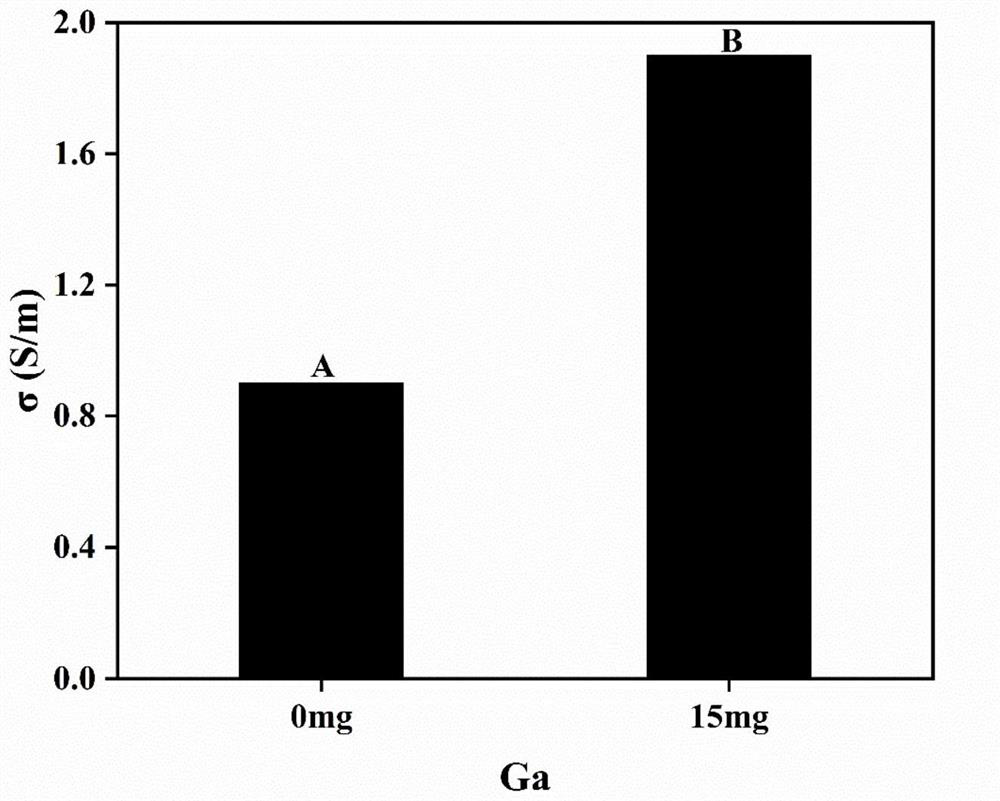

[0030] First dissolve 1.5g acrylamide in 8.6mL deionized water, then add 11.4mL sodium alginate aqueous solution (2%, m / m), stir well, and finally add 0.005g crosslinking agent N,N- Methylene bisacrylamide, 45 μL of accelerator tetramethylethylenediamine and 0.006 g of initiator ammonium persulfate were poured into a mold and heated at 55° C. for 6 hours to form a hydrogel. Then, the hydrogel was soaked in 0.15 M CaCl 2 In the solution for 12 hours, the sodium alginate / polyacrylamide composite hydrogel was obtained. (The molar ratio of sodium alginate to acrylamide is 1:20)

Embodiment 2

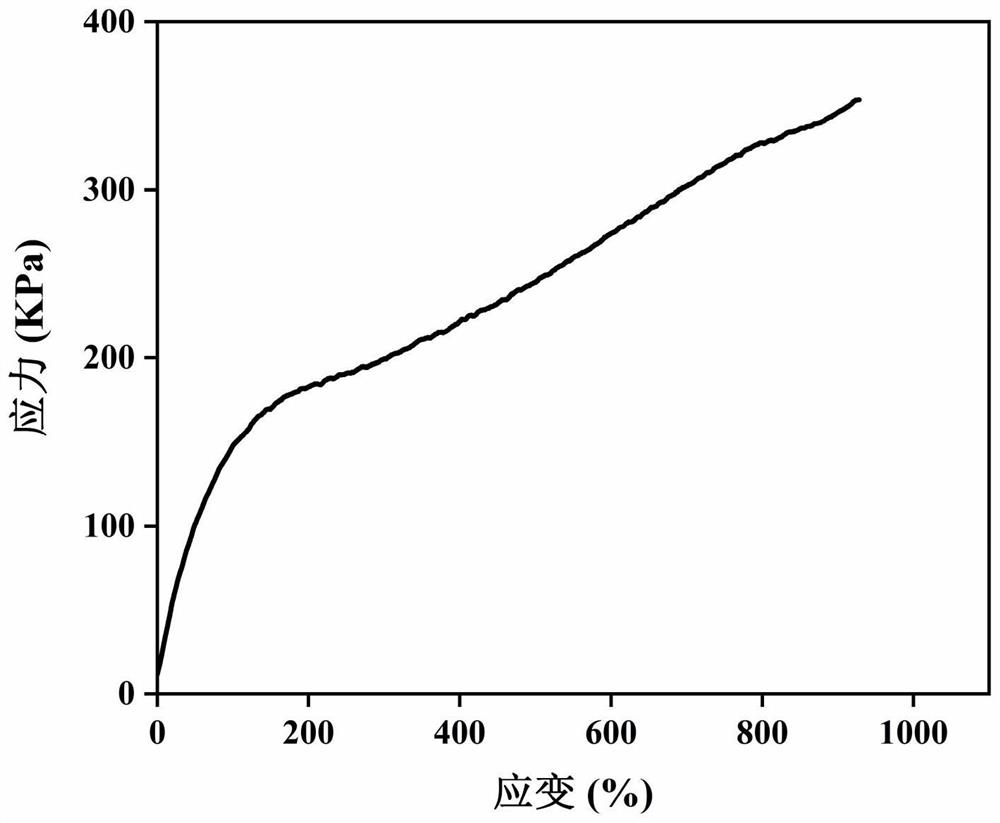

[0032] First dissolve 1.5g of acrylamide in 8.6mL of deionized water, then add 15mg of liquid metal gallium, sonicate, then add 11.4mL of sodium alginate in water (2%, m / m), stir well, and finally in an ice-water bath Add 0.005g crosslinker N,N-methylenebisacrylamide, 45μL accelerator tetramethylethylenediamine and 0.006g initiator ammonium persulfate, pour it into a mold, and heat it at 55°C for 6 hours to form a hydrogel glue. Then, the hydrogel was soaked in 0.15 M CaCl 2In the solution for 12 hours, the gallium / sodium alginate / polyacrylamide composite hydrogel was obtained. (The molar ratio of sodium alginate to acrylamide is 1:20)

Embodiment 3

[0034] First, 1.5 g of acrylamide was dissolved in 10.9 mL of deionized water, then 15 mg of liquid metal gallium was added, sonicated, followed by 9.1 mL of sodium alginate in water (2.5%, m / m), stirred well, and finally in an ice-water bath Add 0.005g crosslinking agent N,N-methylenebisacrylamide, 45μL accelerator tetramethylethylenediamine and 0.006g initiator ammonium persulfate, pour it into the mold, and heat it at 45°C for 4 hours to form a hydrogel glue. Then, the hydrogel was soaked in 0.15 M CaCl 2 In the solution for 18 hours, the gallium / sodium alginate / polyacrylamide composite hydrogel was obtained. (The molar ratio of sodium alginate to acrylamide is 1:20)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com