Tank truck support device

A technology for supporting devices and tank trucks, used in tank trucks, vehicle maintenance, vehicle parts, etc., can solve problems such as tank rupture, stress concentration, and tank rupture risk factor, and achieve a low risk factor and a stress-dispersed problem. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the drawings and embodiments.

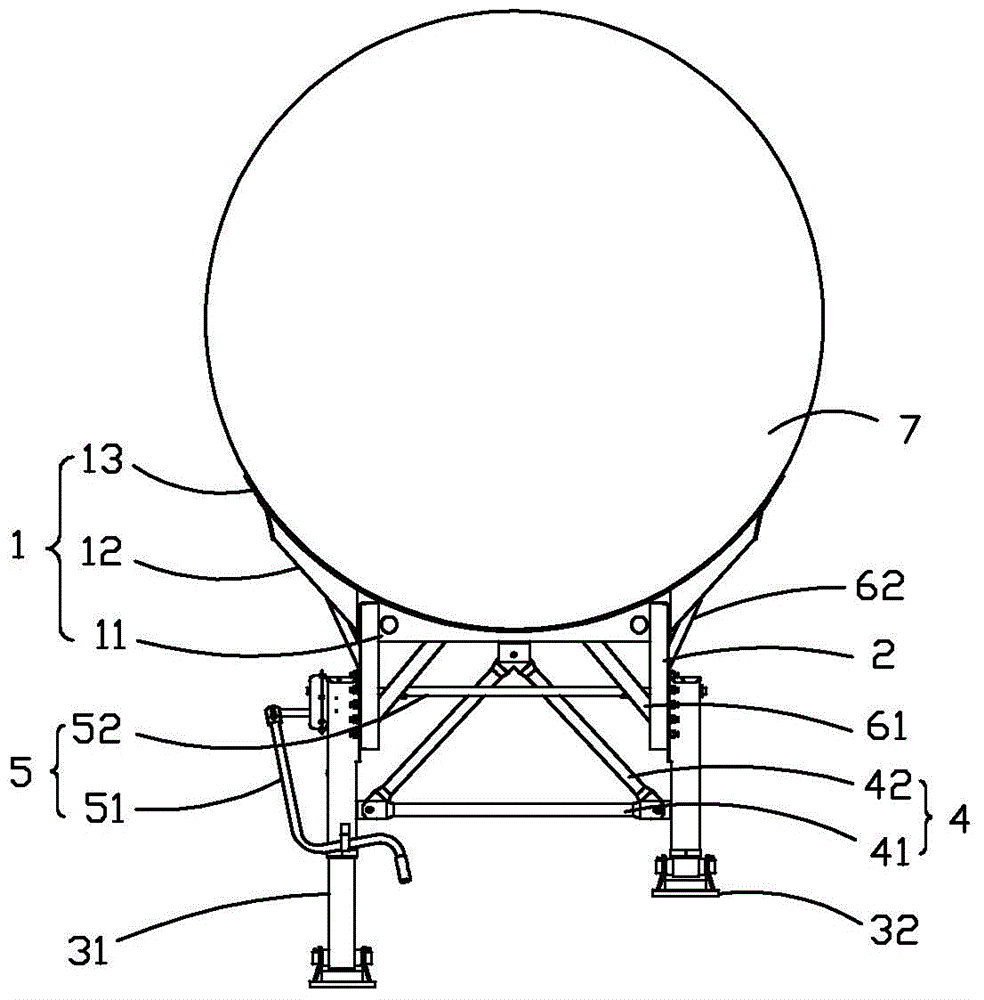

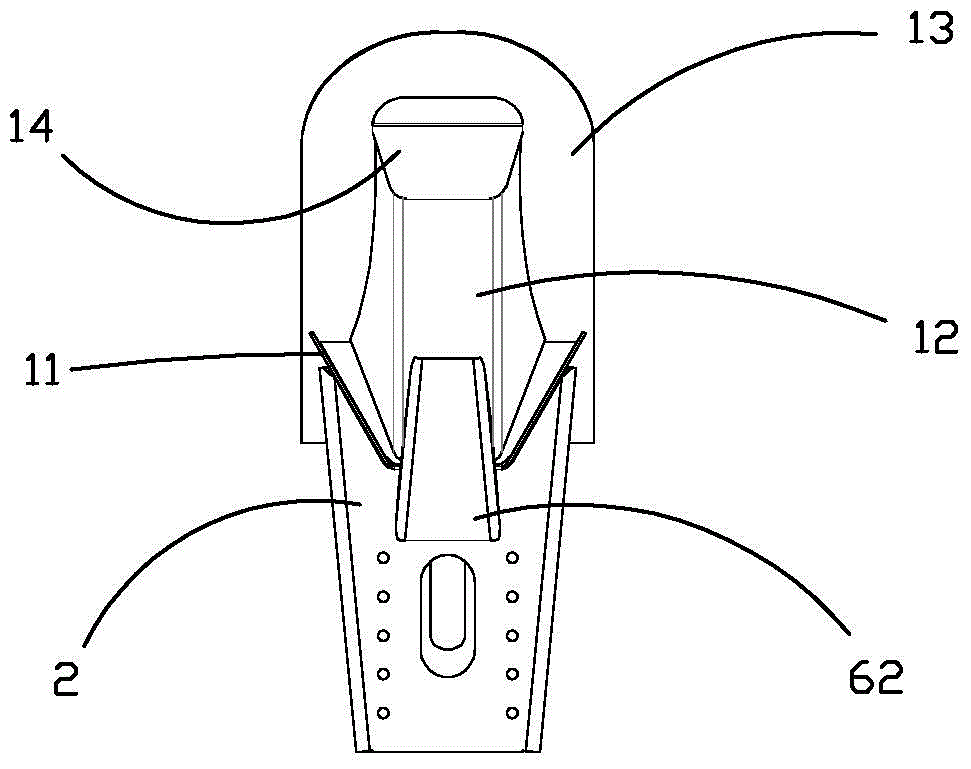

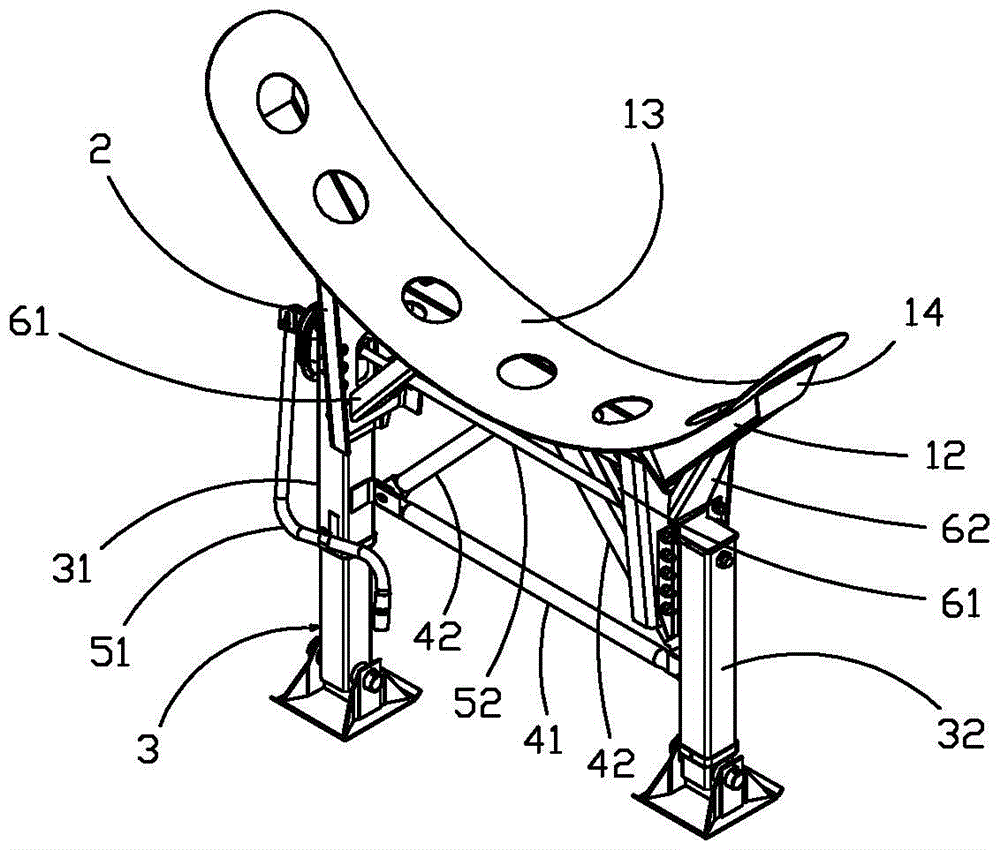

[0022] Such as figure 1 - image 3 As shown, a fuel tank truck support device of the present invention includes two support legs 3 and two support plates 2 respectively fixed on the two support legs 3 and located between the two support legs 3. The fuel tank truck support device also includes a connection The base 1, the reinforcing frame 4, and the two inner support plates 61 located between the two support plates 2 respectively, and the two outer support plates 62 located on the outer sides of the two support plates 2 respectively. The connecting base 1 includes a base 11, respectively fixed to the base The brackets 12 at both ends of the seat 11 and the arc-shaped backing plates 13 fixed on the base 11 and the bracket 12, the base 11 is fixed on the two supporting plates 2, and the reinforcing frame 4 includes a cross bar connecting the two legs 3 41 and two auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com