Tyre reinforcement

A technology for reinforcements and tires, applied in the field of reinforcements for passenger vehicle tires, can solve problems such as crown penetration, rupture, and mechanical fatigue of crown reinforcements, and achieve good penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

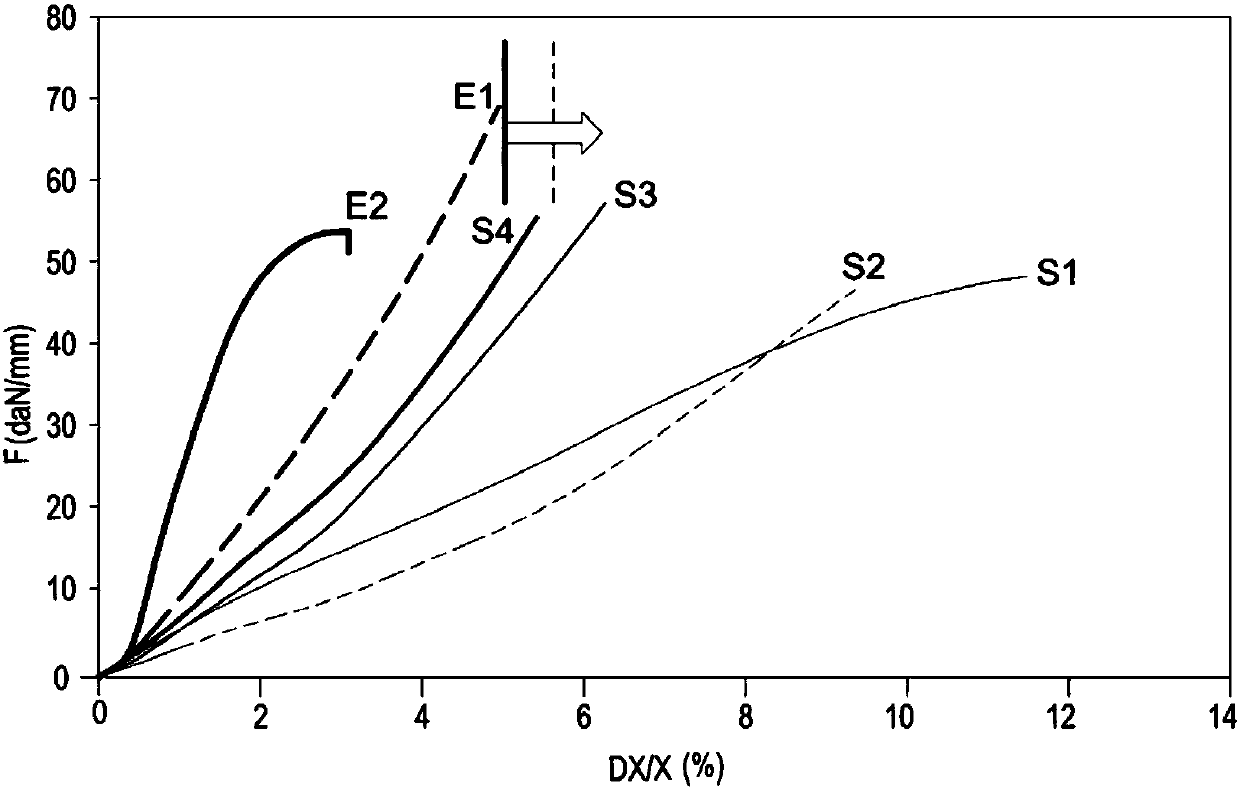

[0058] Establish image 3 The curves in are for nominal pressures intended to fit on 6.5J16 rims and inflated to 2.5 bar at "nominal load" and 2.9 bar at "extra load" according to ETRTO (European Tire and Rim Technical Organization) standards, dimensions Hooping ply for 205 / 55R 16 passenger vehicle tires. Curve S1 is the tensile curve of the hoop layer. The hoop reinforcement of the hoop layer is composed of three 440tex (440 / 3) PET bundles with a balance twist of 160 turns / meter (160tpm). The spacing of the reinforcements is P is equal to 1.31mm. Curve S2 is the tensile curve of the hoop layer. The hoop reinforcement of the hoop layer is a hybrid hoop reinforcement made of a combination of 334tex PET and 330tex aramid fiber with a balance twist of 270 turns / meter (270tpm). Composition, the pitch P of the reinforcement is equal to 0.8mm. Curve S3 is the tensile curve of the hoop layer, the hoop reinforcement of the hoop layer is a hybrid hoop reinforcement, and is made of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com