Device and method for separating objects from silo

A technology for objects and silos, applied in the field of equipment for separating objects from silos, can solve problems such as damage to operating equipment, waste of human resources, and impact on product quality, so as to eliminate manual participation, avoid manual operation errors, and save labor. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing, object of the present invention is described in detail from the equipment and method for separating from the silo:

[0053] refer to figure 2 Objects of the present invention are separated from the structural diagram of the equipment for the silo and image 3 Top view of the apparatus of the invention for separating objects from a silo.

[0054] As shown in the figure, the device for separating objects from the silo according to the present invention includes a silo 20 , a holding member 30 , a pushing device 40 and a material platform 50 .

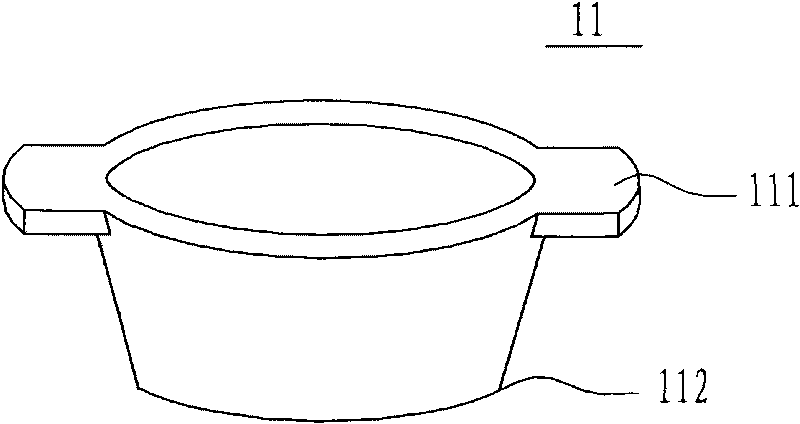

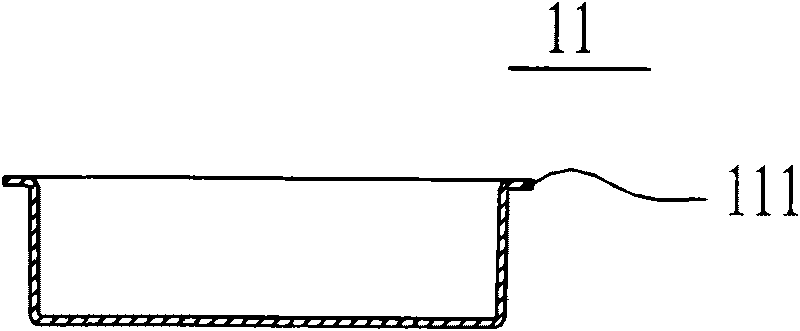

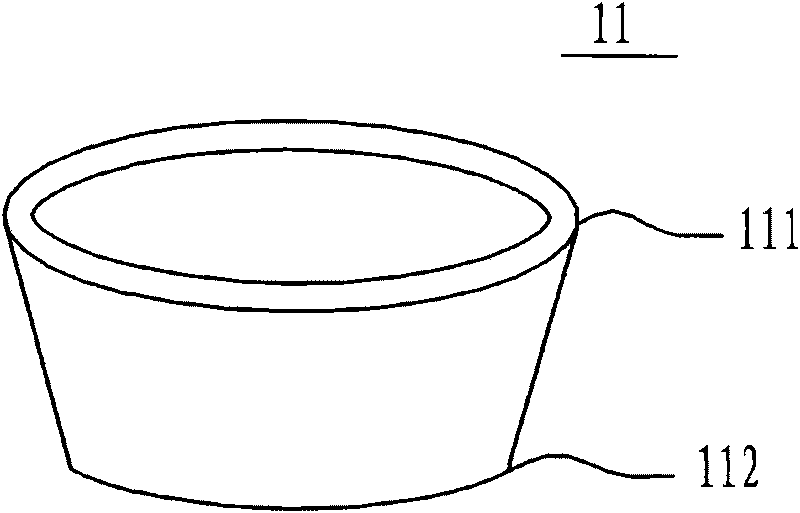

[0055] The silo 20 is used to hold neatly arranged objects 10, wherein the object 10 is a bowl-shaped object or an object with a boss, and its shape can be such as Figure 1a , Figure 1b and Figure 1c The shown shape can of course also be a bowl shape or other non-cylindrical shapes, and this embodiment will be described with a bowl-shaped object as a representative. The silo 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com