Radially regulating sandblasting valve with long life

A long-life, adjustable technology, applied in the direction of grinding/polishing equipment, etc., can solve the problems of sandblasting operations and the short working life of sandblasting valves, and achieve the effect of avoiding early damage and prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

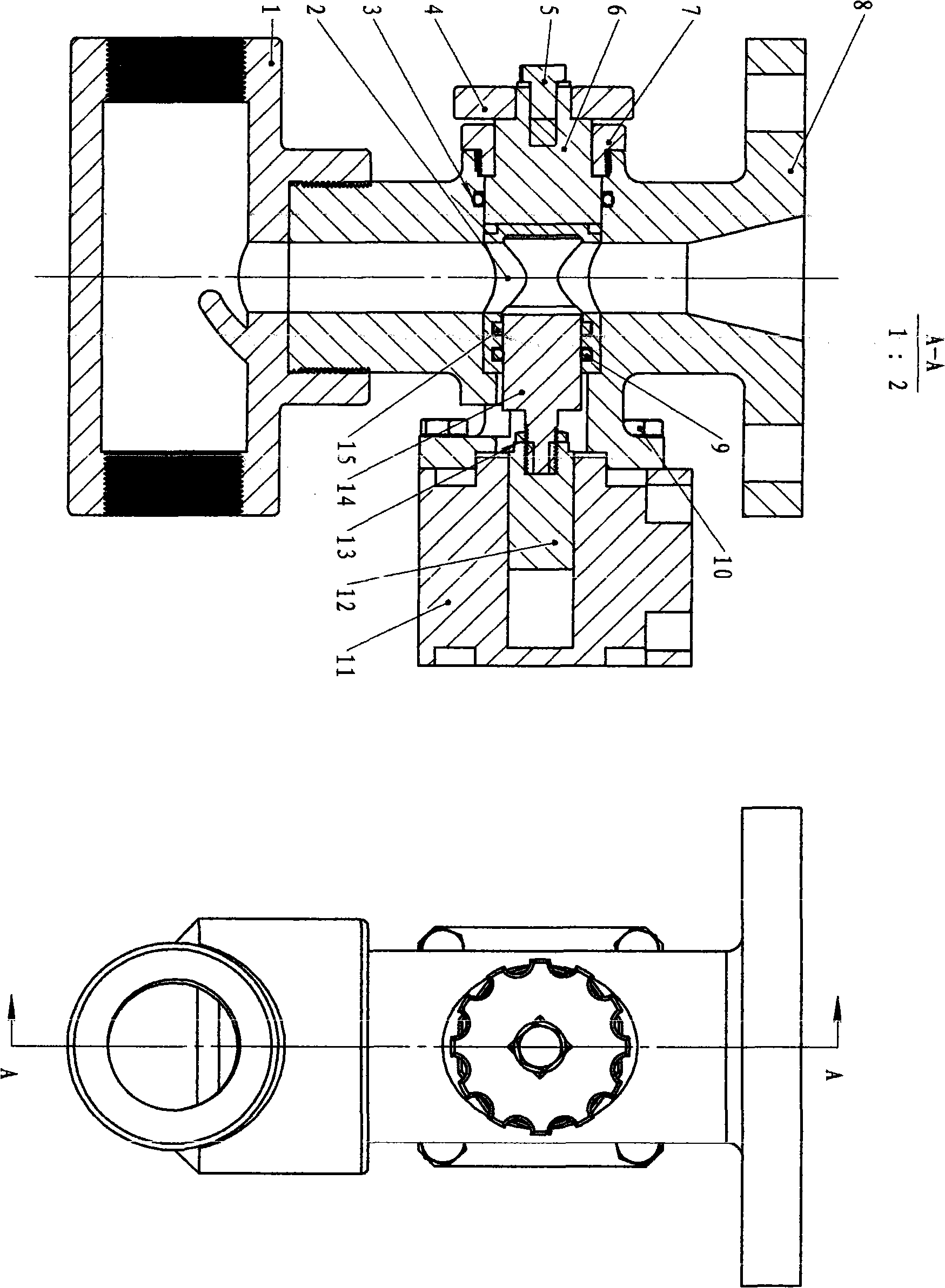

[0007] Attached below figure 1 Describe the specific implementation;

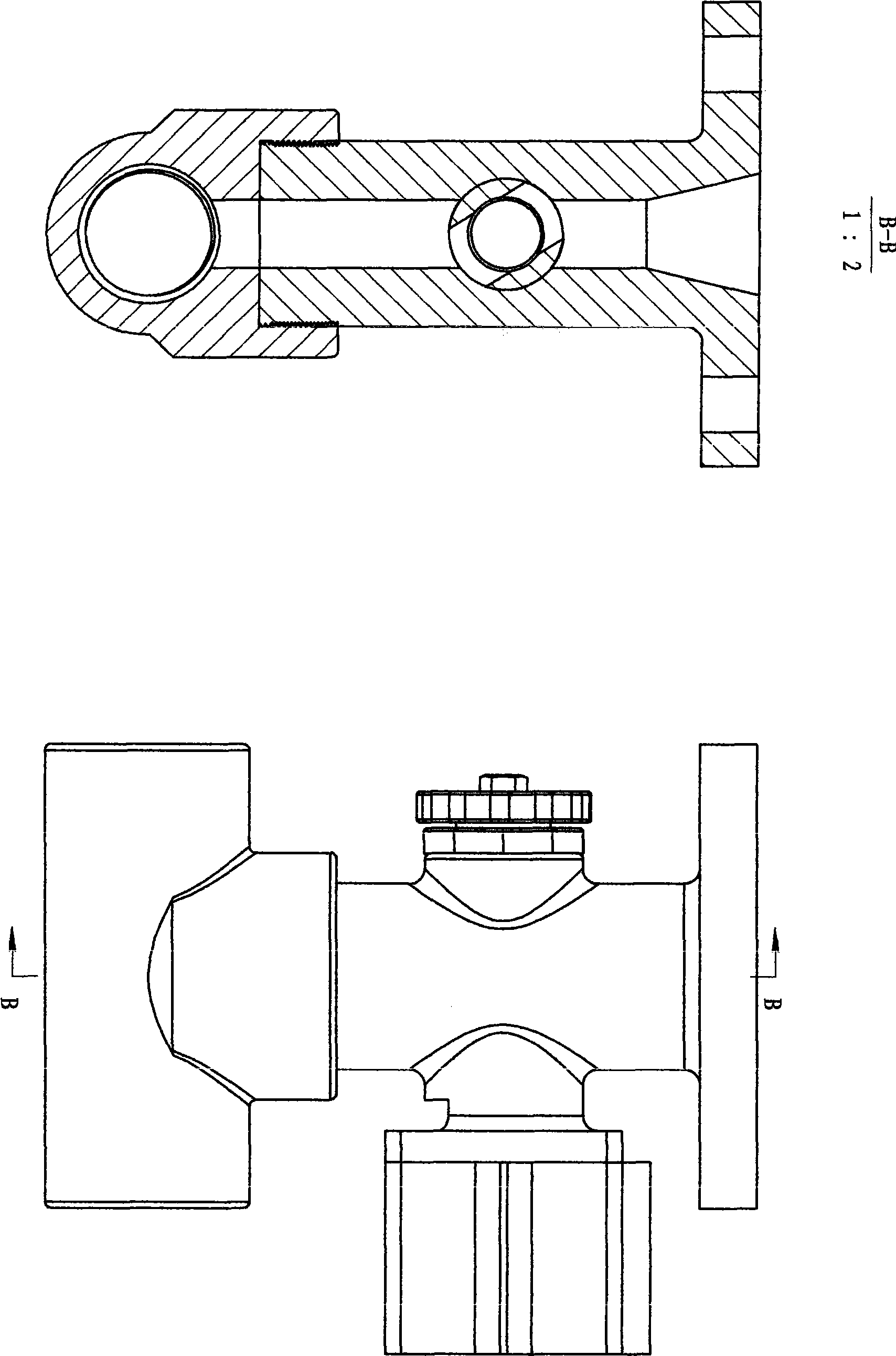

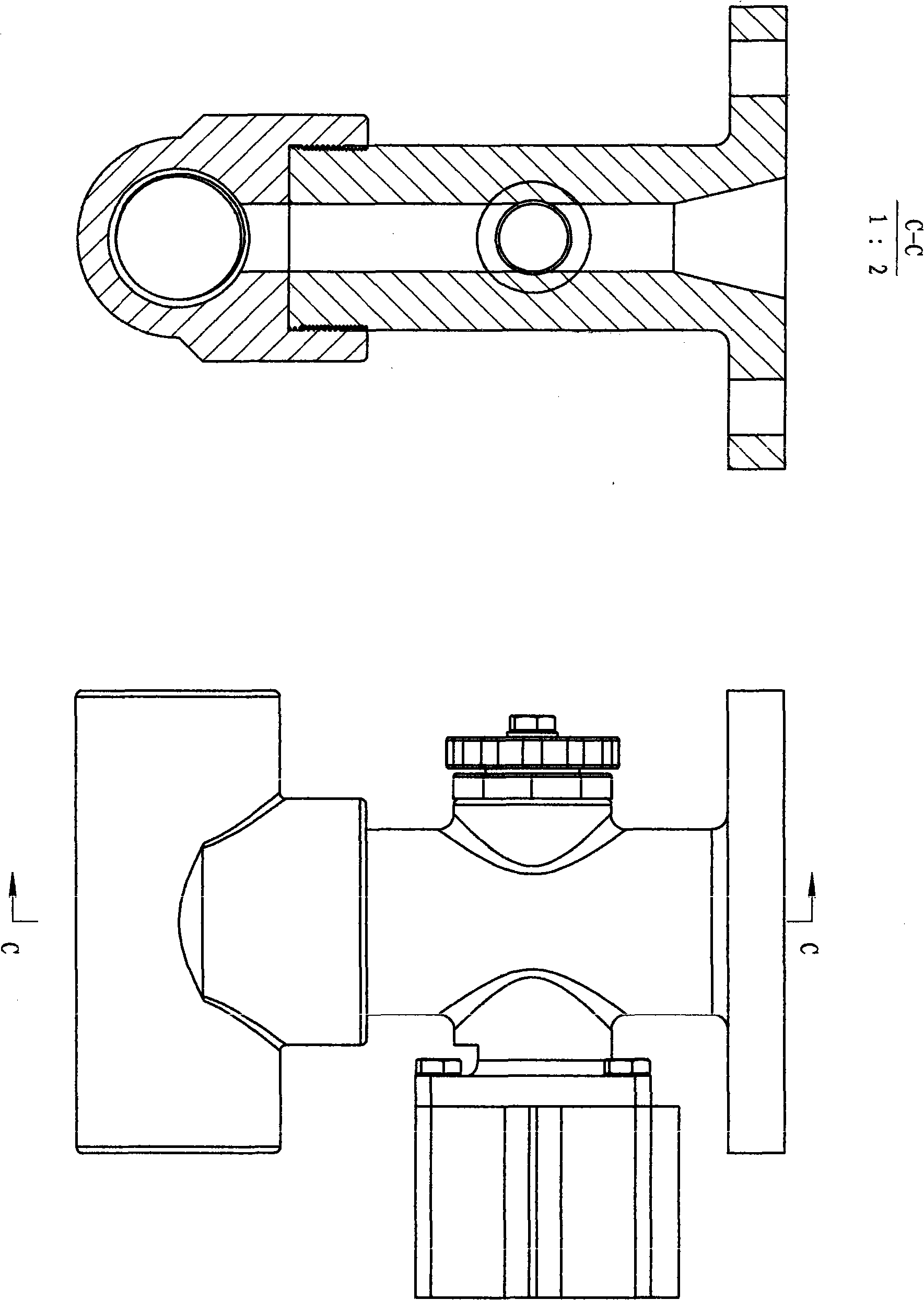

[0008] attached figure 1 The middle cylinder 11 promotes the piston 12 to move to the left, and the spool 14 blocks the upper and lower through holes of the spool cover 2 to close the sand valve. Cylinder 12 pulls piston 12 to move to the right, and the upper and lower through holes of valve core cover 2 are exposed, and sand valve is opened. The handle 4 rotates the valve core sleeve 2 radially through the adjusting claw 6, and radially adjusts the opening and closing size of the upper and lower through holes and the inner hole of the valve body to adjust the sand amount. figure 2 It is the situation when the sand valve partially closes the valve core sleeve and the inner hole of the valve does not overlap, and the amount of sand decreases. attached image 3 It is the view of the coincidence of the valve core sleeve and the inner hole of the valve, and the situation when the amount of sand is the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com