Fatigue-resistant chloroprene rubber air spring air bag and preparation method thereof

An air spring, neoprene technology, applied in the manufacture of spring/shock absorber, spring, spring/shock absorber, etc., can solve the problem of fatigue durability, puncture resistance and air tightness, reduce service life, The influence of the service life of the air spring, etc., can improve the air tightness and interlayer adhesion performance, be easy to manufacture, and ensure the air tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

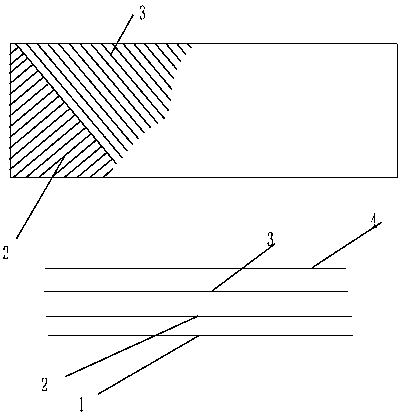

[0028] In specific implementation, the air bag body of the anti-fatigue neoprene air spring is composed of an inner rubber layer, a skeleton reinforcement layer and an outer rubber layer, and the weight ratio of its raw material components is:

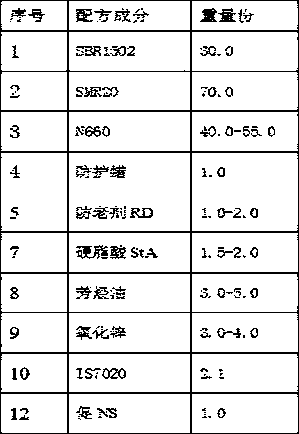

[0029] The inner layer glue and the outer layer glue adopt the same ratio (Table 1):

[0030]

[0031] Cord reinforcing layer adhesive ratio (Table 2):

[0032]

[0033] Between the inner and outer layers of glue, there are two layers of cross-arranged reinforcement layers of the same type of rubberized nylon cord skeleton material.

[0034] The preparation process is carried out as follows:

[0035] 1) Weigh the various raw material components of the inner and outer rubber layers and the skeleton reinforcement layer glue according to the weight ratio, and process them into the inner and outer layer rubber compound and the skeleton reinforcement layer rubber compound by internal mixer and open mixer respectively.

[0036] 2) Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com