PDC (Polycrystalline Diamond Compact) drill bit suitable for shale gas well shale stratum drilling

A technology for shale gas wells and drill bits, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of inability to obtain the ROP and footage, affect the service life of the drill bit, lose the rock-breaking effect, etc., so as to increase the comprehensive use benefit. , The negative cutting angle is suitable, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

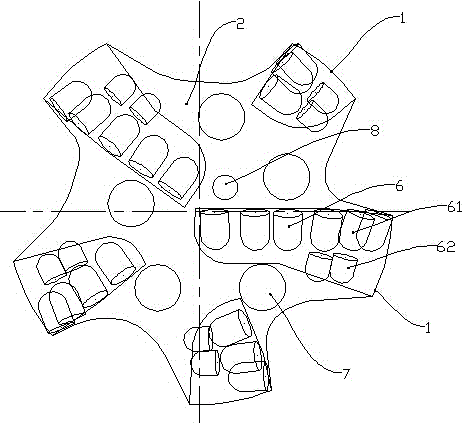

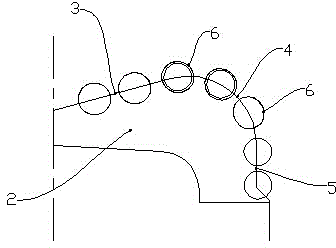

[0012] Such as figure 1 As shown, the PDC drill bit includes a crown 2 with a plurality of blades 1; as figure 2 As shown, the rotary contour line of the crown is composed of three sections: the inner cone section 3 extending outward along the inner cone from the concave center of the drill crown, and the circular arc section 4 extending from the edge of the inner cone to the outer gauge section And the gage section 5 with a straight line profile; the arc section 4 is composed of multiple arcs with different radii, and the radius of the arc gradually increases from the inside to the outside, which ensures the balanced change of the force on the drill bit from the structure and avoids the local teeth Excessive stress; cutting teeth 6 are distributed on these three profiles.

[0013] The cutting teeth 6 are evenly distributed in the inner cone section 3 and the gauge section 4, and the tooth density in the arc section increases with the increase of the radius of the arc. Acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com