Off-the-road tyre tread pattern

A tire tread and construction machinery technology, applied in the field of tire tread patterns, can solve the problems of non-wear resistance, easy sand and stones, and resistance to cutting, so as to improve wear resistance and puncture resistance, and prevent flower collapse block, avoiding early damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

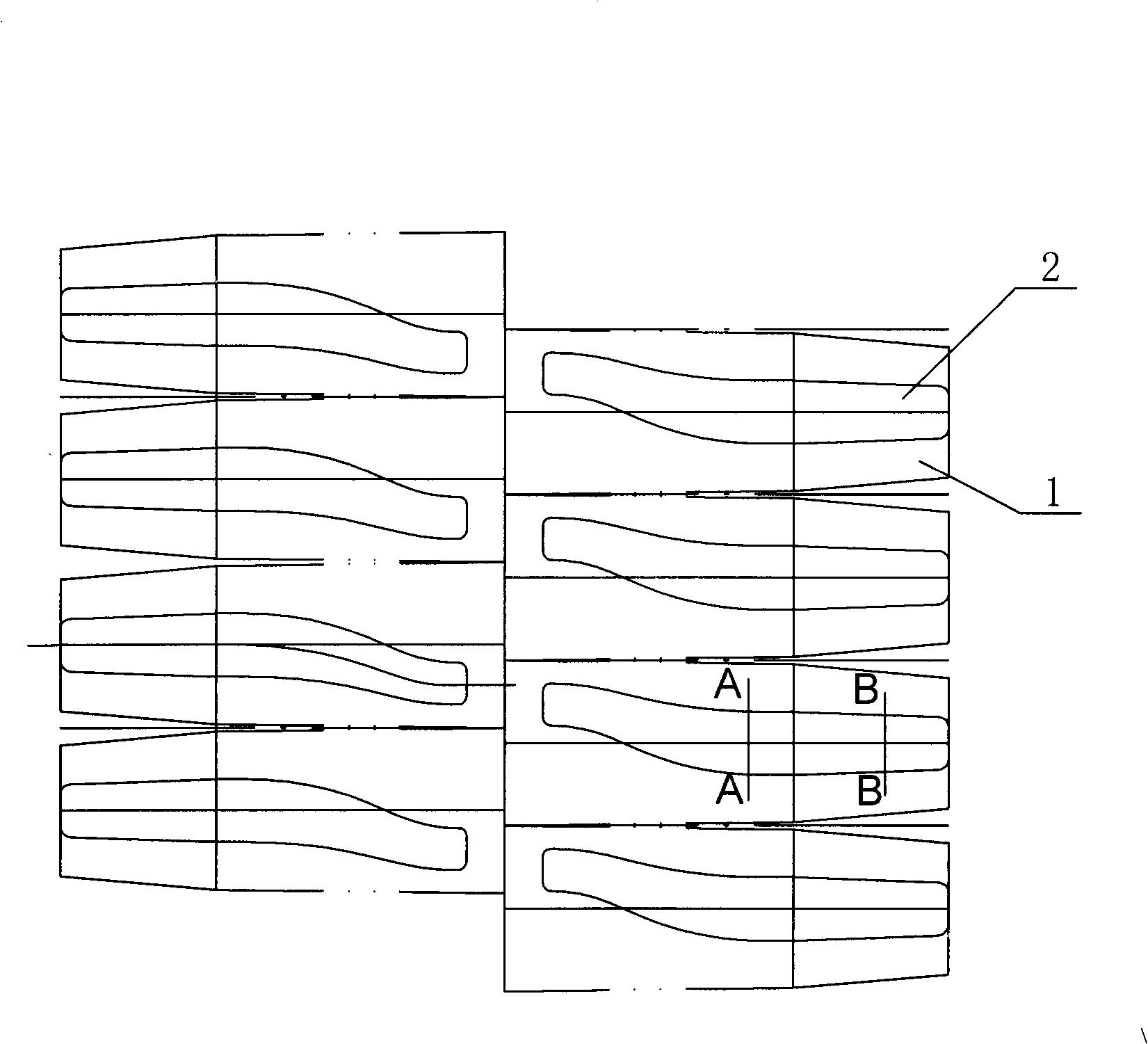

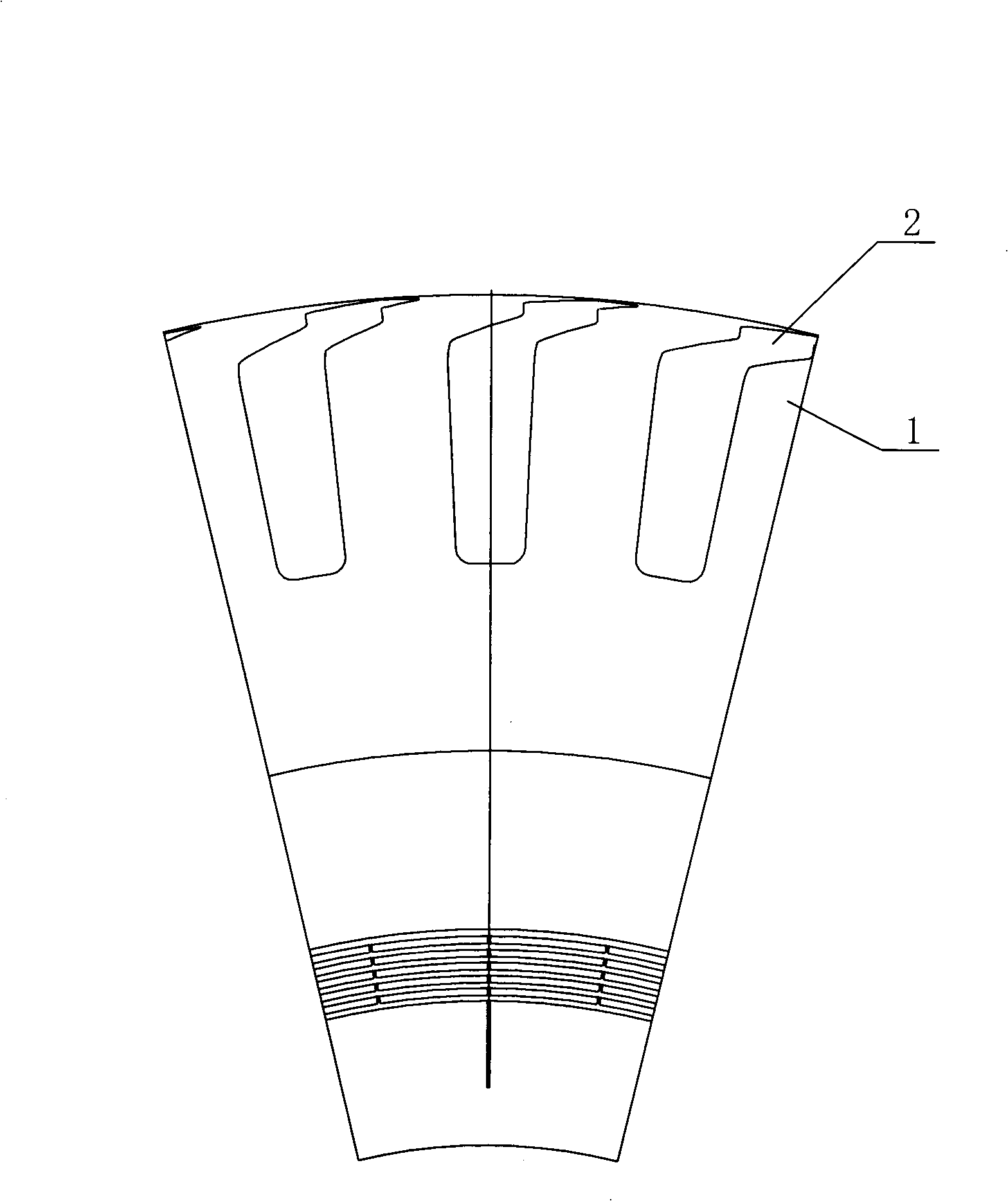

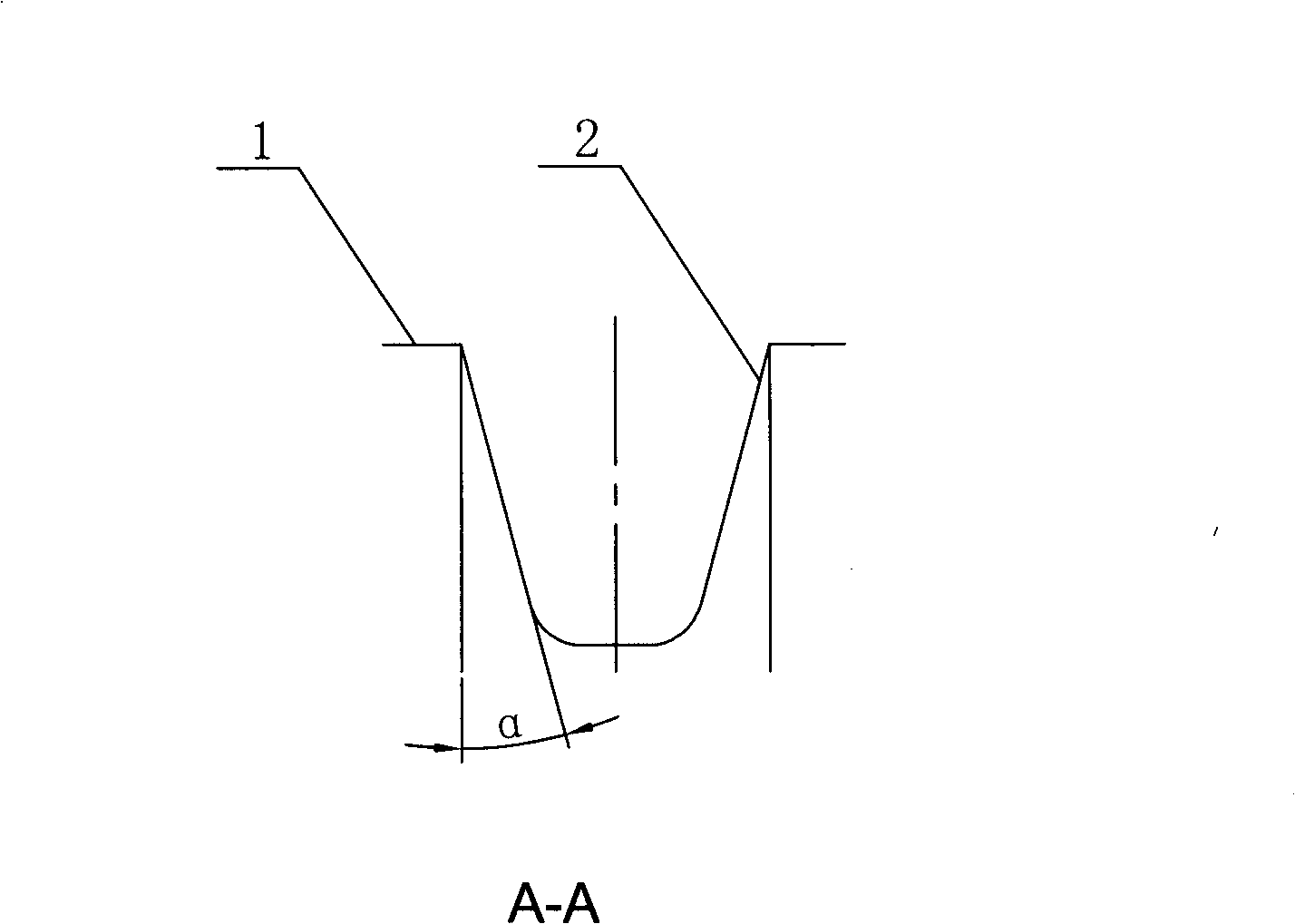

[0022] exist figure 1 In the illustrated embodiment, the present invention is a tread pattern of a bias tire used for a dump truck, including lateral grooves 2 and blocks that are offset in the circumferential direction and are reversely symmetrical with respect to the centerline of the tread 1. The transverse groove 2 starts from the center line of the tread at a position of 6-8% of the tread width to the tire shoulder and extends to the rib groove 2 on the sidewall. The upper and lower grooves of the groove 2 are evenly spaced It is "S" shape, the curvature of the upper groove edge is smaller than that of the lower groove edge; the upper groove edge at the groove head of the pattern groove 2 protrudes outward of the groove, and the upper groove edge of the rest of the crown is recessed toward the groove; The upper groove protruding outside the groove is recessed into the groove along the lower groove edge corresponding to the projected length, and the upper groove recessed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com