A heating film for low-temperature lithium-ion battery and its preparation method and application

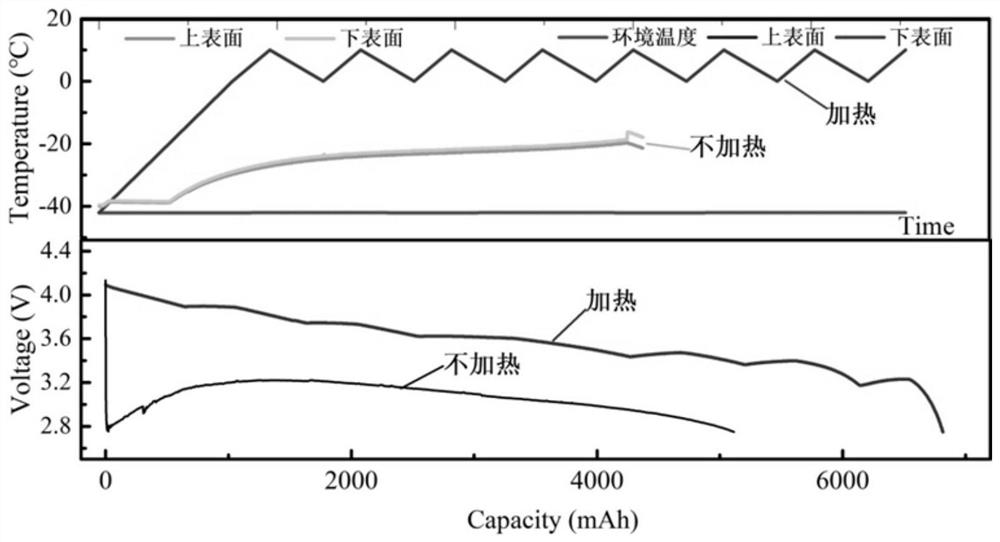

A lithium-ion battery and heating film technology, which is applied in the field of lithium-ion batteries, can solve the problems of easily damaged batteries due to heating, and the low-temperature performance of lithium-ion batteries cannot be played normally, so as to achieve good heating effect, avoid capacity decay, and high heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A heating film for a low-temperature lithium-ion battery, the preparation method of which comprises the following steps:

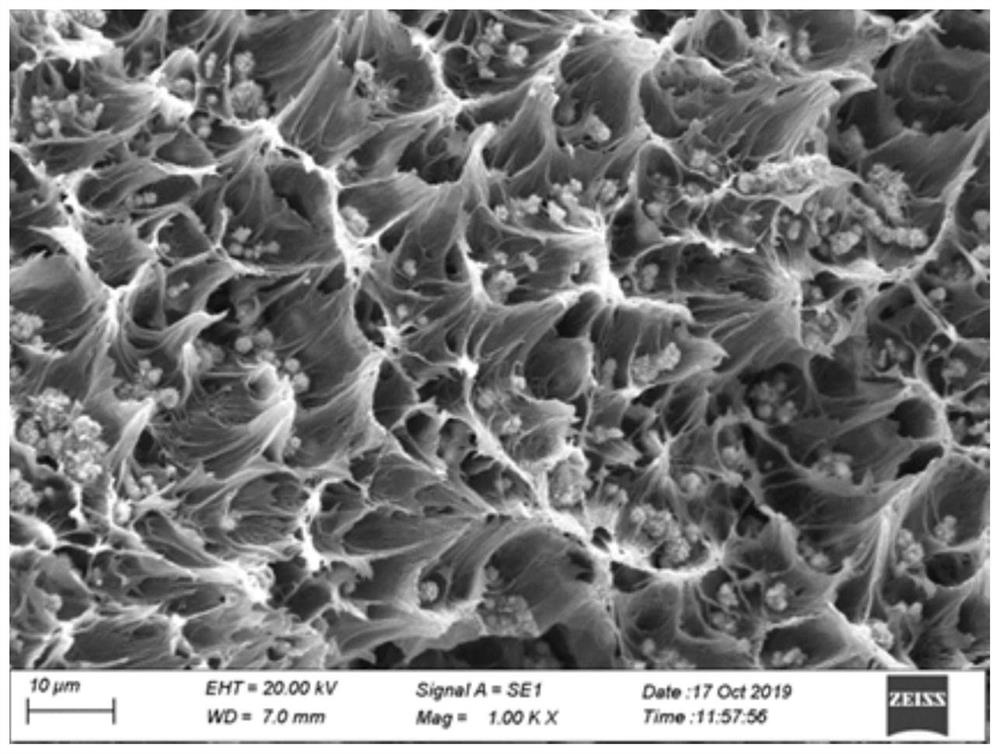

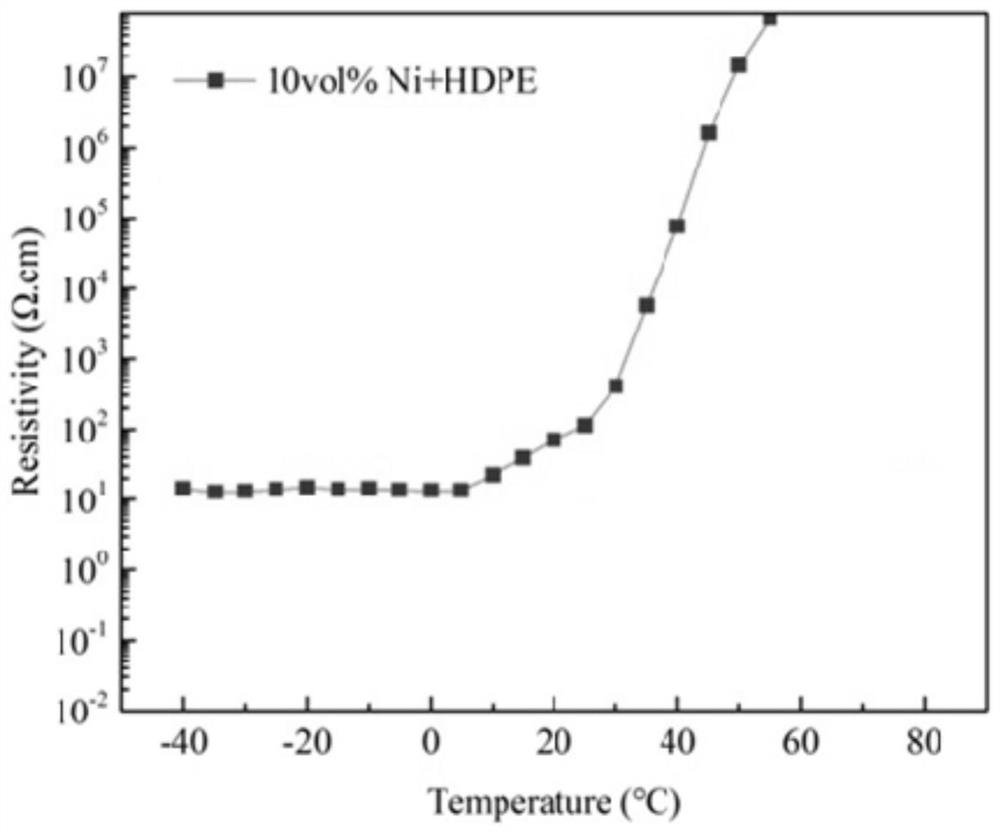

[0029] (1) Add nano-nickel powder into the titanate coupling agent to obtain mixture 1, then mix mixture 1 and low-density polyethylene to obtain mixture 2, and then heat mixture 2 to a molten state at 180°C and stir , to obtain a melt; titanate coupling agent volume accounts for 1% of the nano-nickel powder volume, and the nano-nickel powder volume accounts for 10% of the mixture two volumes (i.e. low density polyethylene and nano-nickel powder volume ratio is 90:10);

[0030] (2) Press the melt obtained in step (1) into a film with a thickness of 1 mm in a hot press molding machine or a hot roll molding machine under the conditions of 150 ° C and 0.6 MPa. Before molding, it is necessary to apply a layer of mold release in the molding mold agent, heat treatment at 120°C for 30 minutes, and cool at room temperature to obtain a heating film for low-t...

Embodiment 2

[0033] A heating film for a low-temperature lithium-ion battery, the preparation method of which comprises the following steps:

[0034] (1) Add nano-silver powder into the titanate coupling agent to obtain mixture 1, then mix mixture 1 and low-density polyethylene to obtain mixture 2, then heat mixture 2 to a molten state at 170° C. and stir, Obtain molten body; Titanate coupling agent volume accounts for 1% of nano-silver powder volume, and nano-silver powder volume accounts for 15% of mixture two volumes (that is low density polyethylene and nano-silver powder volume ratio are 85:15);

[0035] (2) Press the melt obtained in step (1) into a film with a thickness of 1.1mm in a hot press molding machine or a hot roll molding machine under the conditions of 130°C and 0.5MPa. The molding agent is then heat-treated at 110° C. for 25 minutes, and cooled at room temperature to obtain a heating film for a low-temperature lithium-ion battery.

Embodiment 3

[0037] A heating film for a low-temperature lithium-ion battery, the preparation method of which comprises the following steps:

[0038] (1) Add nano-carbon powder into the titanate coupling agent to obtain mixture 1, then mix mixture 1 and polypropylene to obtain mixture 2, and then heat mixture 2 to a molten state at 200°C and stir to obtain Melt body; the volume of titanate coupling agent accounts for 3% of the volume of nano-carbon powder, and the volume of nano-carbon powder accounts for 12% of the volume of the mixture (that is, the volume ratio of polypropylene and nano-carbon powder is 88:12);

[0039] (2) Press the melt obtained in step (1) into a film with a thickness of 0.8mm in a thermocompression molding machine or a hot roll molding machine under the conditions of 160°C and 0.7MPa. The molding agent is then heat-treated at 100° C. for 40 minutes, and cooled at room temperature to obtain a heating film for a low-temperature lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com