Multi-functional fabric and preparation method and application thereof

A multi-functional, fabric technology, applied in textiles and papermaking, physical processing, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of poor electromagnetic shielding performance of fabrics, large load capacity, loose knitting structure, etc., and achieve excellent stability and dispersibility, good peeling and delamination effects, and the effect of preventing uneven tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

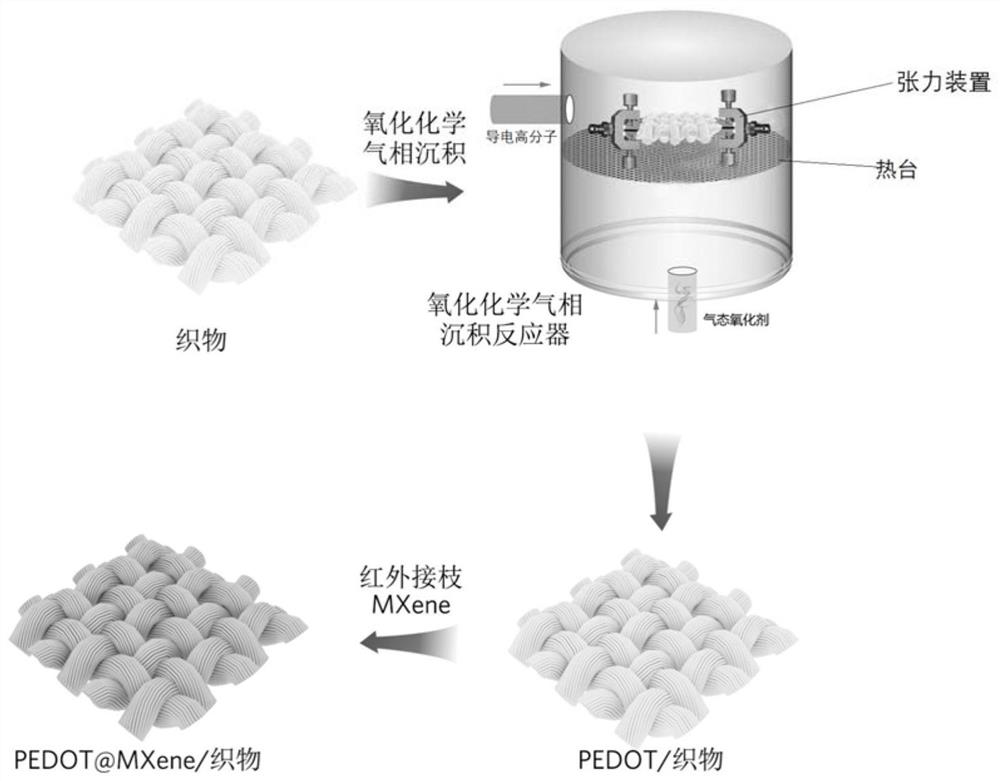

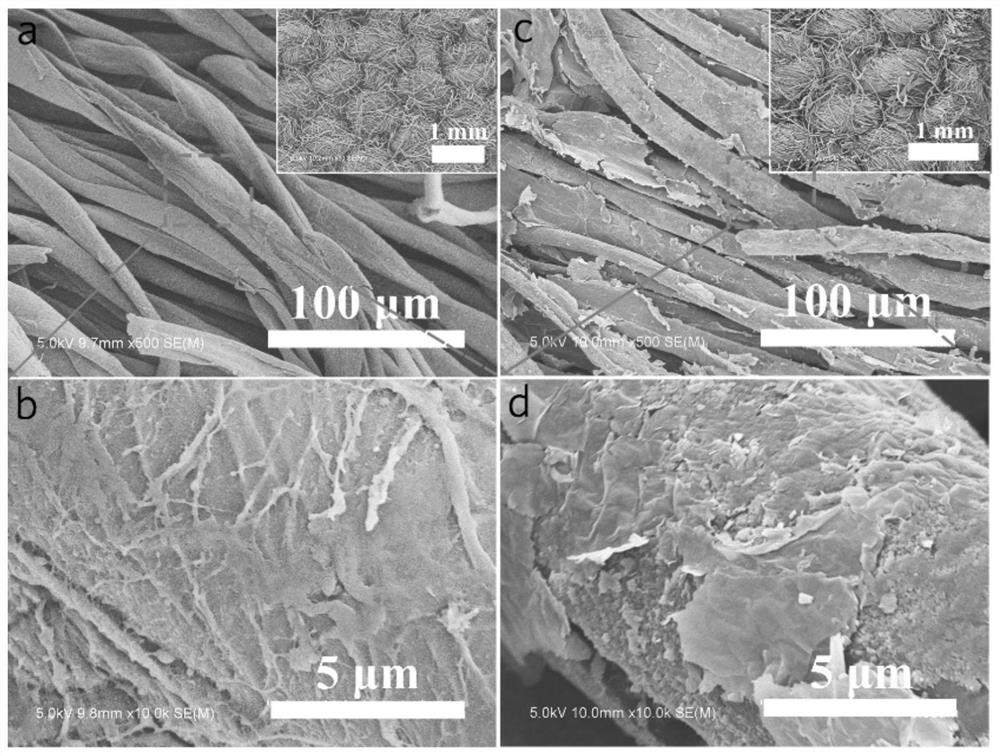

[0063] A method for preparing a multifunctional fabric, comprising the steps of:

[0064] 1) Fabric oxidation chemical vapor deposition of poly-3,4-ethylenedioxythiophene: the cotton fabric is fixed on the hot stage in the oxidation chemical vapor deposition reactor with a pre-tension of 5cN, and the gaseous poly-3,4-ethylenedioxythiophene and vanadium oxychloride (VOCl 3 ) oxidants are transported into the reactor at a certain flow rate and temperature, and polymerized on the surface of the fabric at 80° C. for 60 minutes to prepare poly-3,4-ethylenedioxythiophene-modified fabrics. Among them, the temperature of poly-3,4-ethylenedioxythiophene and vanadyl trichloride delivery pipeline is maintained at 160°C and 60°C respectively; the flow rates of gaseous poly-3,4-ethylenedioxythiophene and oxidant are respectively 9 standard ml / min and 12 NmL / min, the pressure throughout the reactor was maintained at 1 Torr.

[0065] 2) Hydrothermal preparation of ultra-large size MXene di...

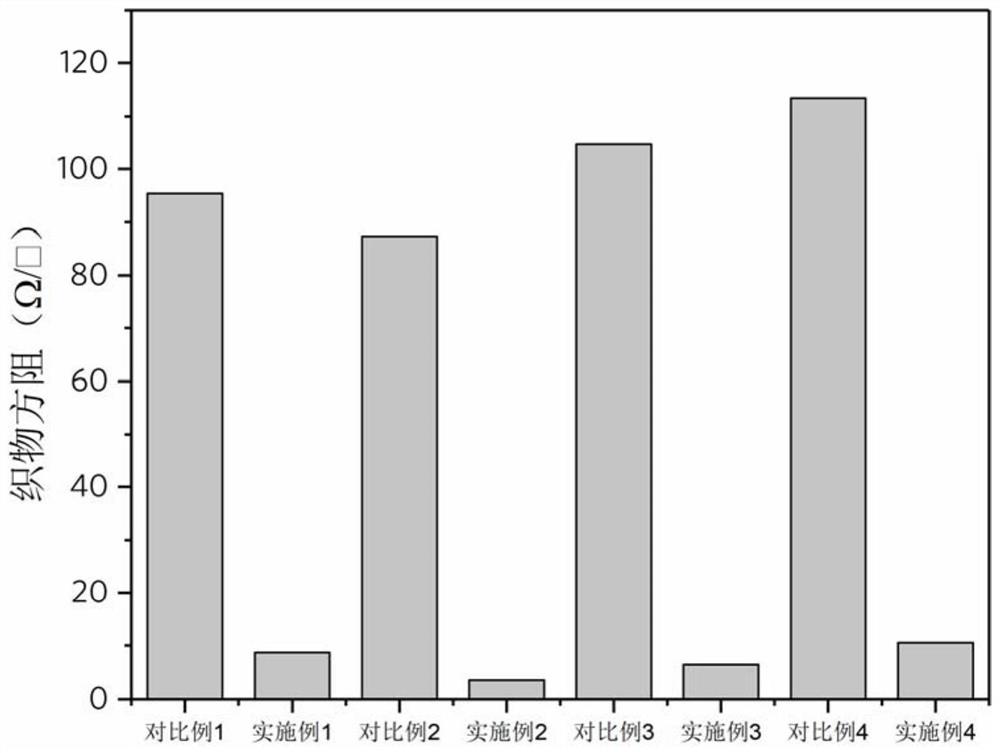

Embodiment 2

[0068] A method for preparing a multifunctional fabric, comprising the steps of:

[0069] 1) Fabric oxidation chemical vapor deposition of poly-3,4-ethylenedioxythiophene: same as step 1) of Example 1, except that the polymerization time is 120 minutes.

[0070] 2) Hydrothermal preparation of super-large-sized MXene dispersion: same as step 2) of Example 1.

[0071] 3) Infrared grafting MXene: same as Step 3) of Example 1, except that the reaction time is 60 minutes.

Embodiment 3

[0073] A method for preparing a multifunctional fabric, comprising the steps of:

[0074] 1) Fabric oxidation chemical vapor deposition of poly-3,4-ethylenedioxythiophene: same as step 1) of Example 1, except that vanadyl trichloride was replaced by iron p-toluenesulfonate.

[0075] 2) Hydrothermal preparation of super-large-sized MXene dispersion: same as step 2) of Example 1.

[0076] 3) Infrared grafting MXene: Same as Step 3) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com