Elastic electrically-driven thermochromic sensing fiber with skin-core structure and preparation method of elastic electrically-driven thermochromic sensing fiber

A thermochromic, skin-core structure technology, applied in the direction of fiber type, fiber processing, fiber chemical characteristics, etc., can not meet the development requirements of device flexibility and wearable, cannot be directly applied in the field of flexible intelligent color changing, does not have Stretchability and other issues, to achieve the effects of excellent electrical conductivity, excellent discoloration properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Pretreatment of polyurethane fiber

[0036] The polyurethane fibers were ultrasonically cleaned with ethanol for 15 minutes to remove surface pollutants. Then, the fibers were immersed in N,N-dimethylformamide solution (DMF) for 1.5 h to make them swell.

[0037] (2) Tannic acid-iron ion surface modification

[0038] Prepare 100mL Tris-HCl (0.01mol / L) buffer solution at room temperature, adjust the pH to 8.3 with NaOH; put the fibers treated in (1) above into 90mL ultrapure water, add 0.8mL Ferric chloride (0.1g / L) was sonicated for 9s to disperse evenly in the solution, then 0.8mL of tannic acid (0.4g / L) was added and sonicated for 8s to be evenly dispersed in the solution, and finally 100mL was added Tris-HCl buffer solution and sonication for 50s.

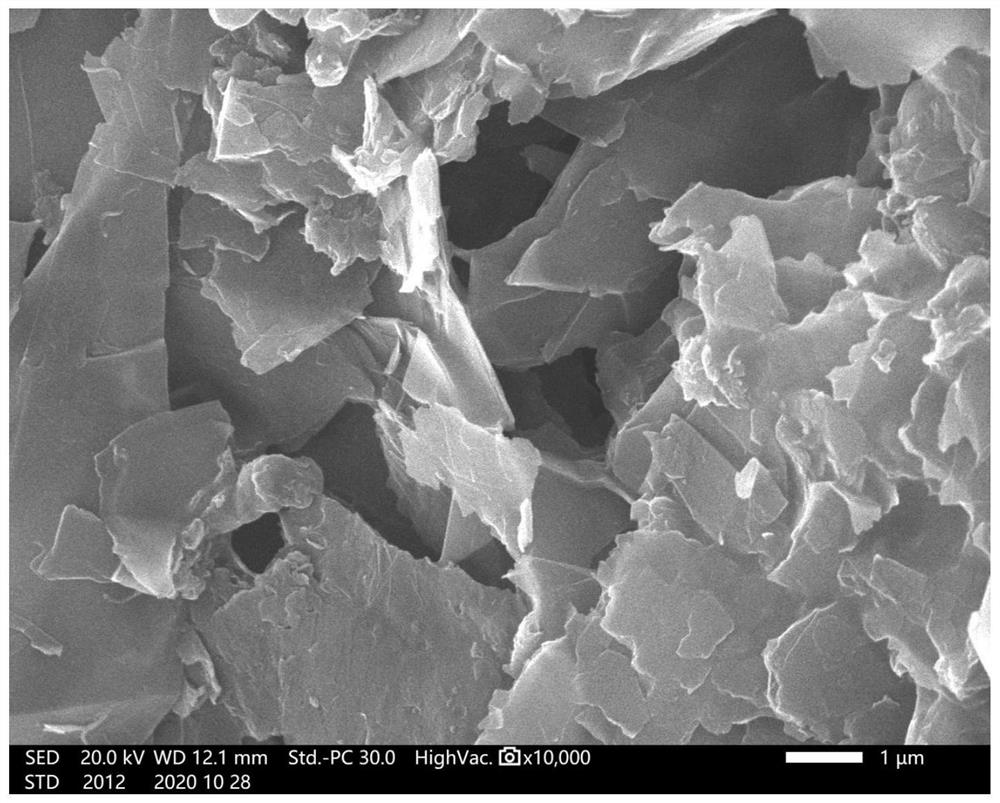

[0039] (3) Preparation of graphene / polyurethane conductive composite fiber

[0040] Submerge the fabric fibers treated in the above step (2) in 15mL of graphene solution (CNC:Graphite=1:1mg / mL) exfoliated by cellu...

Embodiment 2

[0044] (1) Pretreatment of polyurethane fiber

[0045] The polyurethane fibers were ultrasonically cleaned with ethanol for 20 min to remove surface pollutants. Then, the fibers were immersed in N,N-dimethylformamide solution (DMF) for 2 h to make them swell.

[0046] (2) Tannic acid-iron ion surface modification

[0047] Prepare 100mL Tris-HCl (0.01mol / L) buffer solution at room temperature, adjust the pH to 8.5+0.2 with NaOH; put the fibers treated in (1) above into 100mL ultrapure water, add 1mL of ferric chloride (0.1g / L) was ultrasonically treated for 10s to disperse evenly in the solution, then 1mL of tannic acid (0.4g / L) was added and ultrasonically treated for 10s to be evenly dispersed in the solution, and finally 100mL of Tris-HCl buffer solution and sonication for 60s.

[0048] (3) Preparation of graphene / polyurethane conductive composite fiber

[0049] Submerge the fabric fibers treated in the above step (2) in 20mL of graphene solution (CNC:Graphite=1:1.3mg / mL...

Embodiment 3

[0053] (1) Pretreatment of polyurethane fiber

[0054] The polyurethane fibers were ultrasonically cleaned with ethanol for 25 min to remove surface pollutants. Then, the fibers were immersed in N,N-dimethylformamide solution (DMF) for 2.5 h to make them swell.

[0055] (2) Tannic acid-iron ion surface modification

[0056] Prepare 100mL Tris-HCl (0.01mol / L) buffer solution at room temperature, adjust the pH to 8.7 with NaOH; put the fibers treated in (1) above into 110mL ultrapure water, add 1.2mL Ferric chloride (0.1g / L) was sonicated for 12s to disperse evenly in the solution, then 1.2mL of tannic acid (0.4g / L) was added and sonicated for 11s to be evenly dispersed in the solution, and finally 100mL was added Tris-HCl buffer solution and sonication for 70s.

[0057] (3) Preparation of graphene / polyurethane conductive composite fiber

[0058] Submerge the fabric fibers treated in the above step (2) in 25mL of graphene solution (CNC:Graphite=1:1.5mg / mL) exfoliated by cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com