High-weldability environment-friendly superfine solder wire for intelligent manipulator welding and preparation method thereof

A technology of intelligent manipulator and solder wire, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem of easy broken core of solder wire, achieve short production cycle, long quality assurance period, and prevent waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

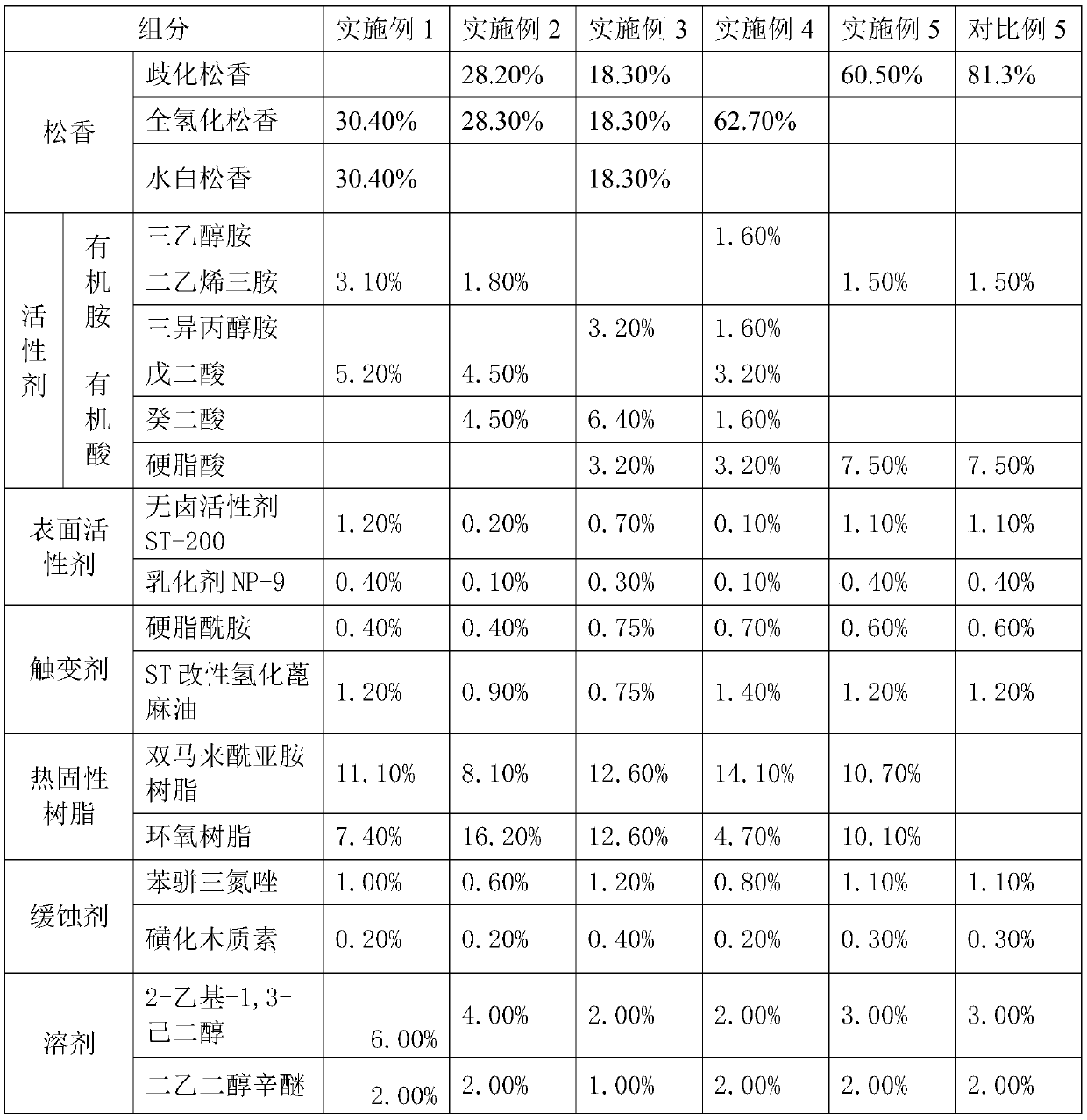

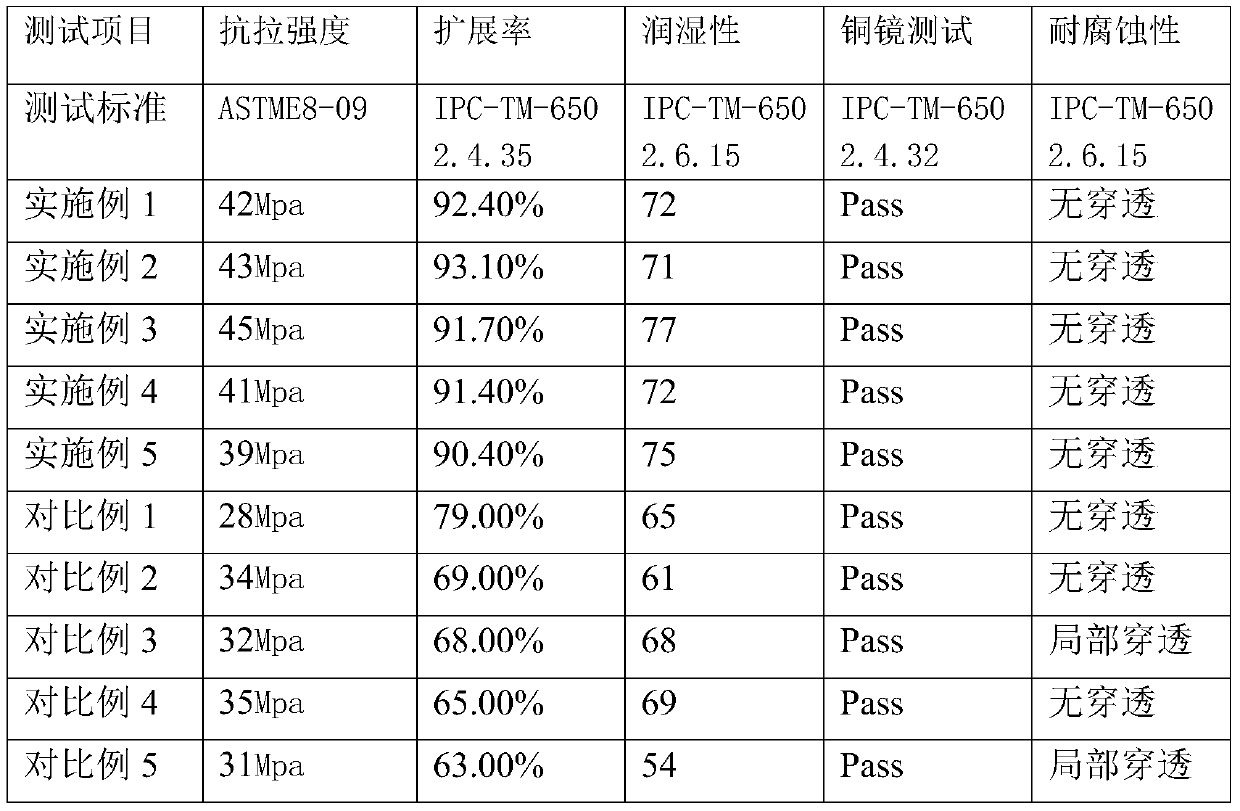

[0030] A high-weldable environment-friendly ultra-fine solder wire for intelligent manipulator welding, including the following components by weight, 97.2% solder alloy, 2.80% flux, wherein the composition of the solder alloy is as shown in Table 2, the flux The composition ratio is described in Table 3, and its preparation method comprises the following steps:

[0031] Weigh each component according to the weight percentages in Table 2 and Table 3, and set aside; add rosin into the reaction kettle and heat to 130°C, add solvent and thermosetting resin and stir for 20 minutes after dissolving, then add thixotropic agent and stir until completely dissolved, Lower the temperature to 90°C, add active agent, surfactant and corrosion inhibitor and stir for 60 minutes, cool to obtain flux; melt the tin into the melting furnace and melt to 360°C, heat and stir for 20 minutes, remove the tin slag, add Stir silver, copper, and molybdenum for 20 minutes, then heat up to 430°C, add ceriu...

Embodiment 2

[0033] A high-weldable environment-friendly ultra-fine solder wire for intelligent manipulator welding, comprising the following components by weight, 97.40% solder alloy, 2.60wt% flux, wherein the composition ratio of the solder alloy is shown in Table 2. The component distribution of flux is as described in table 3, and its preparation method comprises the following steps:

[0034] Weigh each component according to the weight percentages in Table 2 and Table 3, and set aside; add the rosin into the reactor and heat it to 135°C, after it dissolves, add the solvent and the thermosetting resin and stir for 30 minutes, then add the thixotropic agent and stir until it is completely dissolved. Lower the temperature to 80°C, add active agent, surfactant and corrosion inhibitor and stir for 50 minutes, cool to obtain flux; melt the tin into the melting furnace and melt to 350-360°C, keep stirring for 250min, then remove the tin slag , add silver, copper, molybdenum and stir for 10 m...

Embodiment 3

[0036] A high-weldability environment-friendly ultra-fine solder wire for intelligent manipulator welding, comprising the following components by weight, 96.9wt% solder alloy, 3.1wt% flux, wherein the composition ratio of the solder alloy is shown in Table 2, The component distribution of flux is as described in table 3, and its preparation method comprises the following steps:

[0037] Weigh each component according to the weight percentages in Table 2 and Table 3, and set aside; add rosin into the reaction kettle and heat to 150°C, after dissolving, add solvent and thermosetting resin and stir for 2 minutes, then add thixotropic agent and stir until completely dissolved, Lower the temperature to 80°C, add active agent, surfactant and corrosion inhibitor and stir for 40 minutes, cool to obtain flux; melt the tin into the melting furnace and melt to 355°C, keep stirring for 25 minutes, remove the tin slag, add Stir silver, copper and molybdenum for 10 minutes, then raise the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com