Graphene-carbon nanotube composite film material and preparation method and application thereof

A carbon nanotube composite and carbon nanotube film technology, which is applied in the field of graphene-carbon nanotube composite film materials and its preparation, can solve the problems of increasing furnace energy consumption, high energy consumption, and time-consuming production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

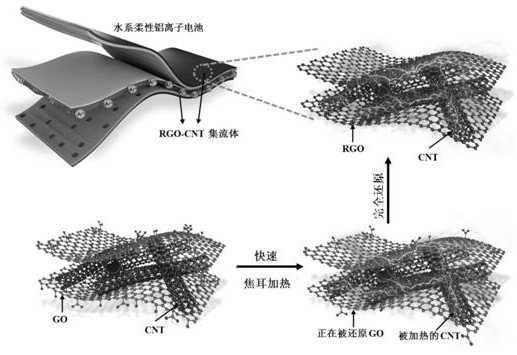

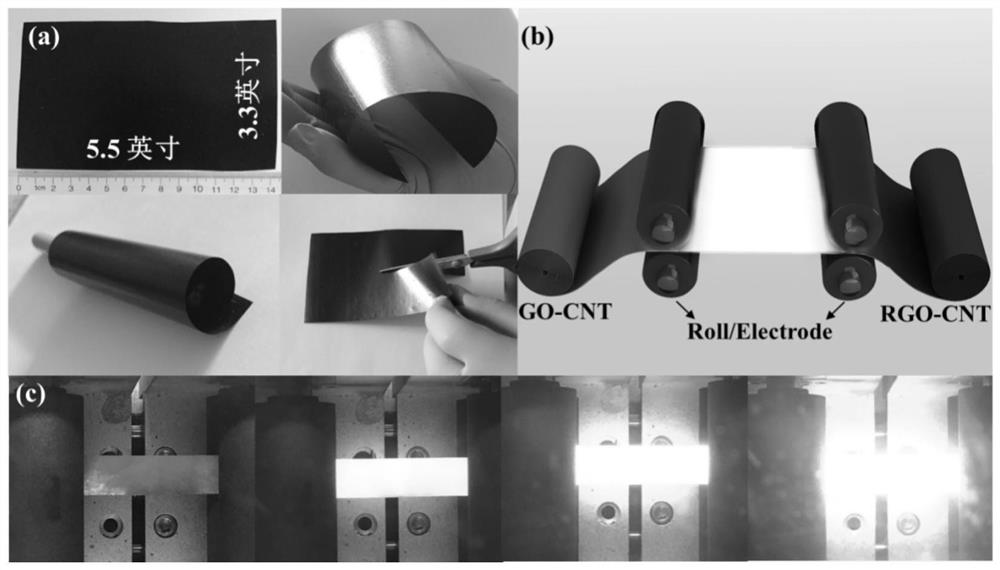

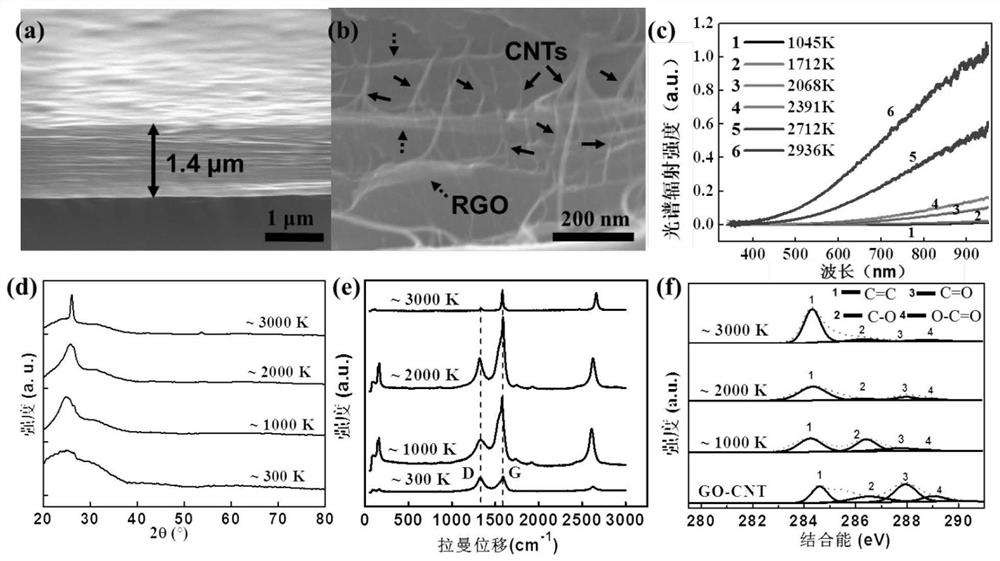

[0036] The preparation of graphene-carbon nanotube composite film material is carried out according to the following steps:

[0037] Step 1, preparation of GO-CNT: add 100mg single-walled carbon nanotubes into 200mL ethanol, after 30s ultrasonic treatment, get 0.5mg / mL carbon nanotube (CNT) ink, add 100mg graphene oxide (GO) Ink (3mg / mL) and carbon nanotube (CNT) ink are mixed and sonicated according to the CNT concentration of 15wt%, to obtain a graphene-carbon nanotube (GO-CNT) mixed solution, and the obtained graphene-carbon nanotube The mixed solution of tube (GO-CNT) was evenly dropped onto the Teflon plate cleaned by ethanol, so that the mixed solution was evenly spread on the entire Teflon plate, and then the above-mentioned Teflon plate was placed at room temperature (20-25°C) ) to dry naturally to obtain graphene oxide-carbon nanotube composite film material (GO-CNT);

[0038] Step 2, Joule heating process: the graphene oxide-carbon nanotube film material (GO-CNT) is...

Embodiment 2

[0041] The preparation of graphene-carbon nanotube composite film material is carried out according to the following steps:

[0042] Step 1, preparation of GO-CNT: add 100mg single-walled carbon nanotubes into 200mL ethanol, after 30s ultrasonic treatment, get 0.5mg / mL carbon nanotube (CNT) ink, add 100mg graphene oxide (GO) Ink (3mg / mL) and carbon nanotube (CNT) ink are mixed and sonicated according to the CNT concentration of 15wt%, to obtain a graphene-carbon nanotube (GO-CNT) mixed solution, and the obtained graphene-carbon nanotube The mixed solution of tube (GO-CNT) was evenly dropped onto the Teflon plate cleaned by ethanol, so that the mixed solution was evenly spread on the entire Teflon plate, and then the above-mentioned Teflon plate was placed at room temperature (20-25°C) ) to dry naturally to obtain graphene oxide-carbon nanotube composite film material (GO-CNT);

[0043] Step 2, Joule heating process: place the graphene oxide-carbon nanotube film material (GO-C...

Embodiment 3

[0045] The preparation of graphene-carbon nanotube composite film material is carried out according to the following steps:

[0046] Step 1, preparation of GO-CNT: add 100mg single-walled carbon nanotubes into 200mL ethanol, after 30s ultrasonic treatment, get 0.5mg / mL carbon nanotube (CNT) ink, add 100mg graphene oxide (GO) Ink (3mg / mL) and carbon nanotube (CNT) ink are mixed and sonicated according to the CNT concentration of 15wt%, to obtain a graphene-carbon nanotube (GO-CNT) mixed solution, and the obtained graphene-carbon nanotube The mixed solution of tube (GO-CNT) was evenly dropped onto the Teflon plate cleaned by ethanol, so that the mixed solution was evenly spread on the entire Teflon plate, and then the above-mentioned Teflon plate was placed at room temperature (20-25°C) ) to dry naturally to obtain graphene oxide-carbon nanotube composite film material (GO-CNT);

[0047] Step 2, Joule heating process: place the graphene oxide-carbon nanotube film material (GO-C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com