Composite electric heating paint for flexible base material as well as preparation method and use thereof

A technology of electrothermal coatings and flexible substrates, applied in conductive coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor heat resistance, low heating temperature, and low heating rate, and achieve excellent oxidation resistance , Excellent heating performance, excellent electric heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A composite electrothermal coating, the specific formula includes in parts by weight: 14.25 parts of spherical graphite powder (manufacturer: Harbin Tianbao Graphite Co., Ltd., particle size ≤ 20nm), 0.75 parts of copper powder (specification: analytically pure, size: 200 mesh) , 15 parts of polyurethane resin (manufacturer: Hubei New Sihai Chemical Co., Ltd., model: 60D4), 30 parts of cyclohexanone, 5 parts of dioctyl phthalate, 0.8 parts of Tween-20, 1.5 parts of stearic acid , 1.5 parts of magnesium oxide, 1.5 parts of zinc oxide.

[0034] First, accurately weigh the pretreated spherical graphite powder and copper powder and place them in the reaction container, add the relevant additives listed in the formula, and add 1 / 3 of the solvent cyclohexanone to make each component, especially the graphite The powder is fully saturated.

[0035] The mixed components after infiltration are fully dispersed under the high-speed shear emulsifier of 3000rad / min.

[0036] After ...

Embodiment 2

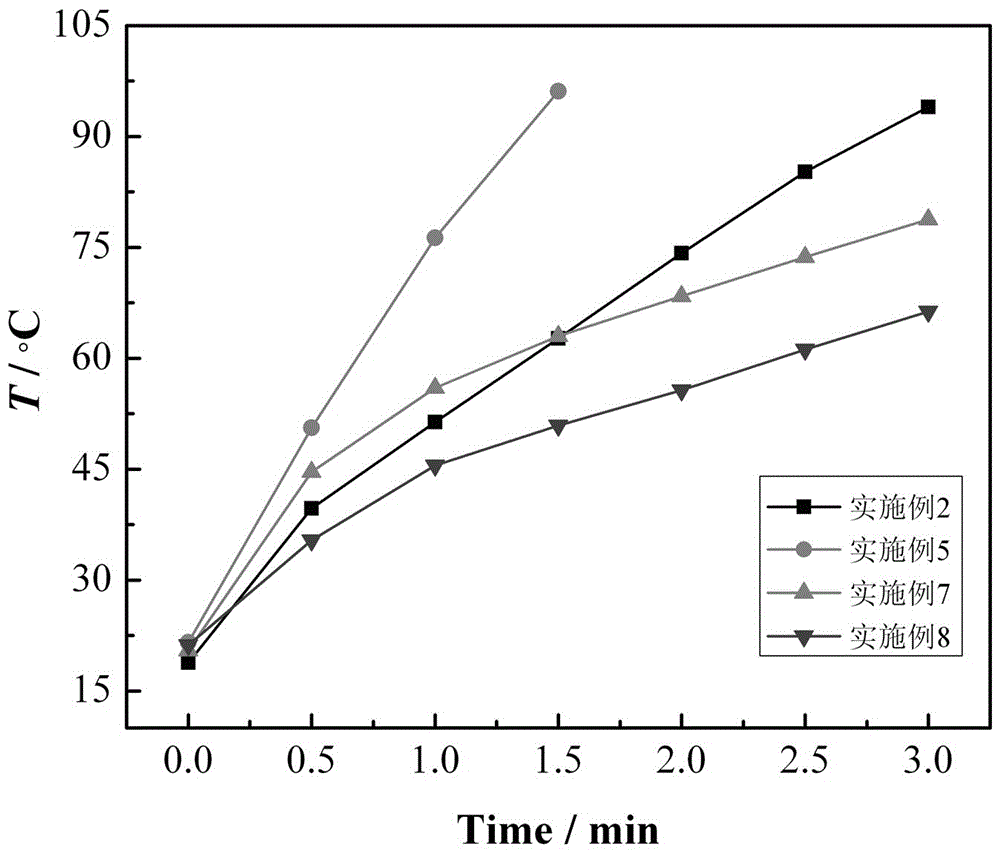

[0040] The formula of Example 2 is similar to that of Example 1, except that the conductive filler in Example 2 is 14.25 parts of flake graphite and 0.75 parts of copper powder.

[0041] The preparation method of the composite electric heating coating and the preparation method of the electric heating material are the same as in Example 1.

[0042] Test results: the resistance of the electrothermal material in Example 2 is about 450Ω.

Embodiment 3

[0044] Embodiment 3 and Embodiment 4 are similar to Embodiment 1, except that the coating thickness in Embodiment 3 is 0.1 mm after drying, and the coating thickness in Embodiment 4 is 0.3 mm after drying.

[0045] The preparation method of the composite electrothermal coating and the preparation method of the electrothermal coating are the same as in Example 1.

[0046] Test results: the resistance of the electrothermal material in Example 3 is about 860Ω, and the resistance of the electrothermal material in Example 4 is about 730Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com