Packaging piece based on substrate and adopting slotting technology and manufacturing process of packaging piece

A package and substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as poor heat dissipation of EPBGA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

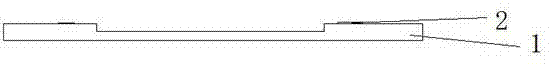

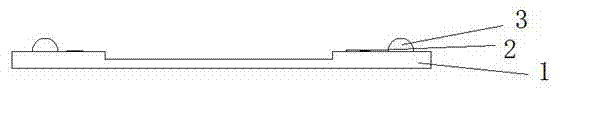

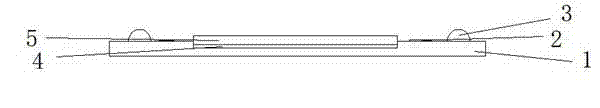

[0018] Such as Image 6 As shown, a substrate-based package using slotting technology is mainly composed of lead frame 1 , PAD 2 , solder ball 3 , conductive glue 4 , chip 5 , bonding wire 6 and plastic package 7 . There are PAD2 and solder ball 3 on the lead frame 1, and there is a notch, the lead frame 1 is connected with a chip 5 in the notch through the conductive glue 4, and the solder joint on the chip 5 is bonded to the PAD2 on the lead frame 1 The wire 6 is connected, the chip 5, the bonding wire 6, the solder ball 3, and the lead frame 1 constitute the power supply and signal channel of the circuit, and the plastic package 7 surrounds the lead frame 1, PAD2, solder ball 3, chip 5 and bonding wire 6 , the plastic package 7 supports and protects the chip 5 , the bonding wire 6 and the solder ball 3 .

[0019] The bonding wire 6 includes gold wire, copper wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com