Preparation method of multifunctional super-hydrophobic composite material

A conductive composite material, super-hydrophobic technology, applied in electromagnetic measuring devices, fiber types, textiles and papermaking, etc., can solve problems such as corrosion of composite materials and limit practical applications, and achieve poor environmental applicability, excellent use stability and high temperature resistance performance, the effect of excellent moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

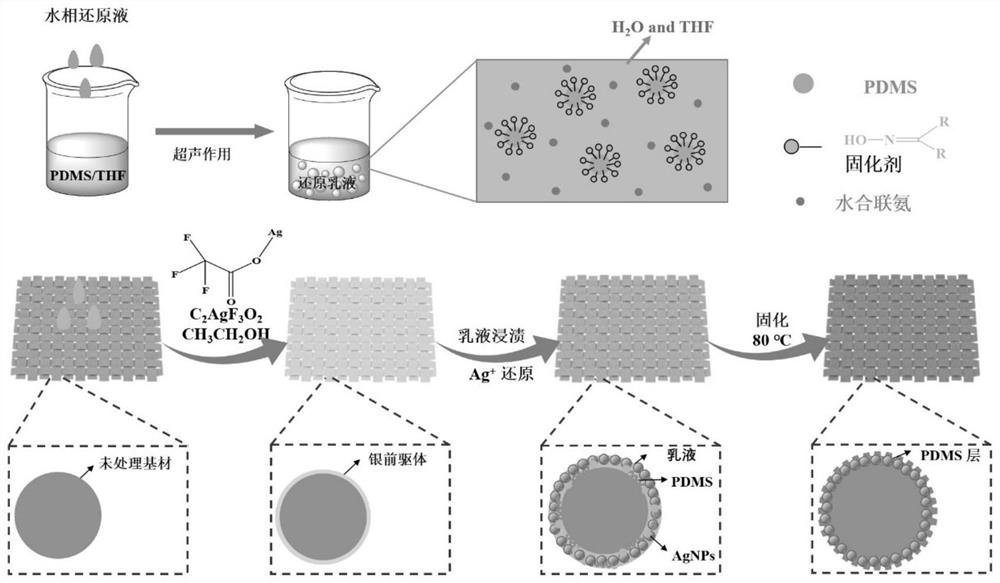

[0035] The flexible substrate (nylon elastic fabric) was soaked in the ethanol solution (10 wt %) of the silver precursor (STA) for 1h to obtain a pretreated substrate with STA adsorbed, and the precursor in the solution could be evenly distributed On the surface of the substrate, it is more conducive to the subsequent formation of a uniform conductive network system. Dilute 5 g of hydrazine hydrate solution (AR, with a purity of 80%) with 15 g of deionized water to obtain an aqueous phase with a mass concentration of hydrazine hydrate of 20%, dilute 0.4 g of dimethylsiloxane with 19.56 g of tetrahydrofuran (THF) and solidify it 0.04 g of dimethylsiloxane was used to obtain an oil phase with a mass concentration of dimethylsiloxane of 2%, wherein the commercially available SYLGARD 184 DOW CORNING was used for dimethylsiloxane and its curing agent. The water phase is used as a poor solvent to cause interfacial effects, and the oil phase is used as an emulsifier. The water phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com