High-elastic electric-induced-heating compound film and preparation method thereof

An electric heating and composite film technology, which is applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the complex processing technology of metal electric heating film, the heavy quality of electric heating materials, and the influence on the application of electric heating materials, etc. problems, to achieve the effect of strong designability, stable electric heating performance, and stable and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Garment lining elastic film

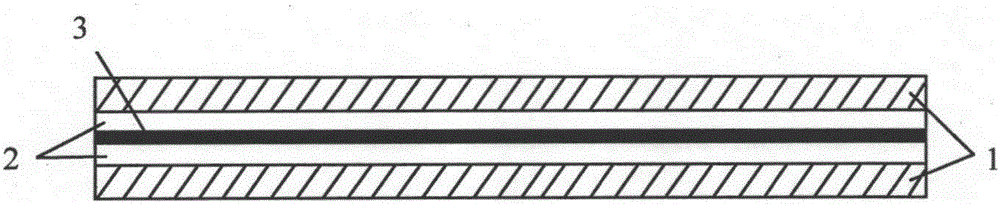

[0035] Such as figure 1 As shown, an electrothermal composite film includes an elastic film 1 and a flexible nano-conductive film 3 bonded to the upper side of the elastic film 1 by an adhesive 2, and the upper side of the flexible nano-conductive film 3 is bonded The agent 2 bonds another elastic film 1 .

[0036] The preparation method of the above-mentioned electrothermal composite film, the specific steps are:

[0037] Step 1: After immersing the carbon nanotube film in the graphene suspension for 3 hours, take it out, and let it dry naturally at room temperature to obtain a flexible nanoconductive film. Coat both ends of the flexible nanoconductive film with conductive silver glue, and wire the copper wire The electrode is inserted into the conductive silver glue, and the copper wire electrode is adhered to the conductive silver glue;

[0038] The selected size of the carbon nanotube film is 40*40mm 2 The carbon nanot...

Embodiment 2

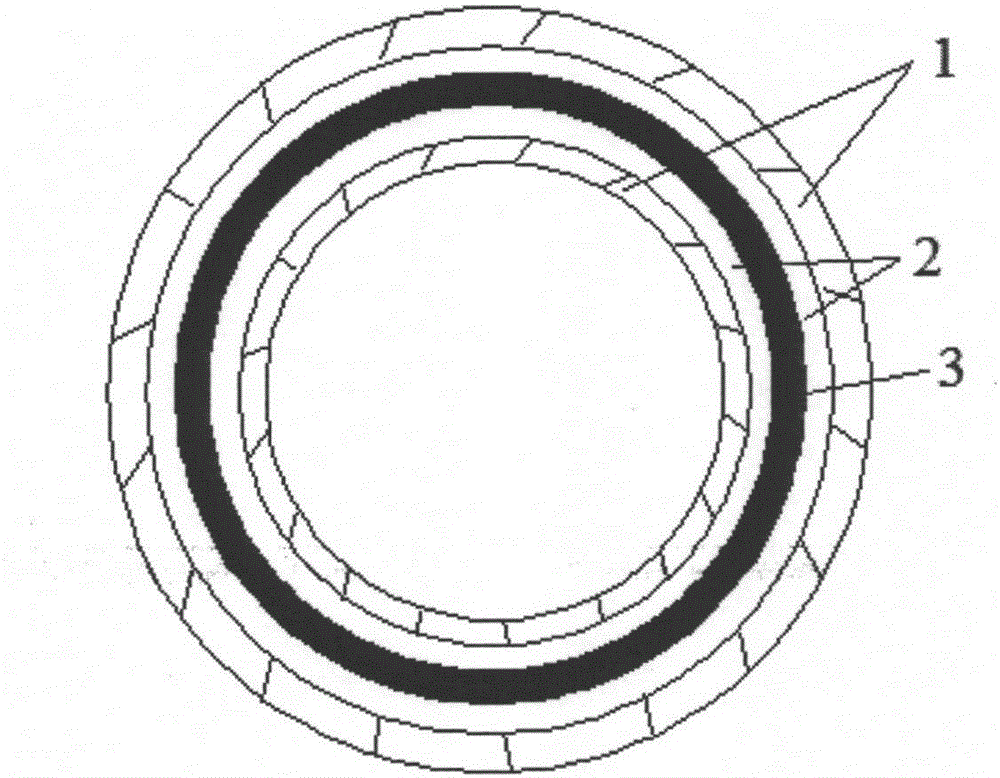

[0044] Example 2: Elastic thermal insulation film for heating pipes

[0045] Such as figure 2 As shown, an electrothermal composite film includes an elastic film 1 and a flexible nano-conductive film 3 bonded to the upper side of the elastic film 1 by an adhesive 2, and the upper side of the flexible nano-conductive film 3 is bonded The agent 2 bonds another elastic film 1 . The first and last ends of the electrothermal composite film are bonded to form a ring structure.

[0046] The preparation method of the above-mentioned electrothermal composite film, the specific steps are:

[0047] Step 1: Immerse the carbon nanotube film in the graphene suspension for 3 hours, take it out, and dry it naturally at room temperature to obtain a flexible nanoconductive film;

[0048] The carbon nanotube film is the same as in Example 1. The concentration of the graphene suspension is 2mg / ml, the immersion time is 3h, and the number of immersion times is 1 time.

[0049] Step 2: Use the ...

Embodiment 3

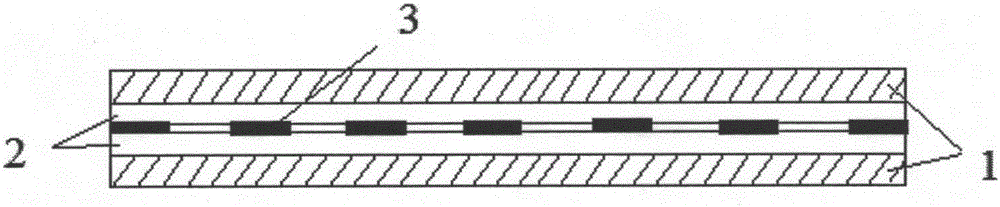

[0054] Example 3: Anti-fog film for bathroom mirror

[0055] Such as image 3 As shown, an electrothermal composite film includes an elastic film 1 and a flexible nano-conductive film 3 bonded to the upper side of the elastic film 1 by an adhesive 2, and the upper side of the flexible nano-conductive film 3 is bonded The agent 2 bonds another elastic film 1 .

[0056] The preparation method of the above-mentioned electrothermal composite film, the specific steps are:

[0057] Step 1: Immerse the carbon nanotube film in the graphene suspension for 3 hours, take it out, and dry it naturally at room temperature to obtain a flexible nanoconductive film;

[0058] The carbon nanotube film with a size of 1m*10mm (Suzhou Institute of Nanotechnology and Nano-Bionics, Chinese Academy of Sciences) is selected for the carbon nanotube film, which is obtained from multi-walled carbon nanotubes. The diameter of the carbon nanotubes is 10-50nm, and the film thickness 20μm, porosity 75%, te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com