Semiconductor packaging structure and preparation method thereof

A packaging structure and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of difficulty in ensuring vertical interconnection of different layers, low integration of antenna packaging structures, and high packaging costs , to achieve the effect of saving production and development costs, meeting the requirements of three-dimensional packaging, good electrical and thermal performance and high-efficiency antenna performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

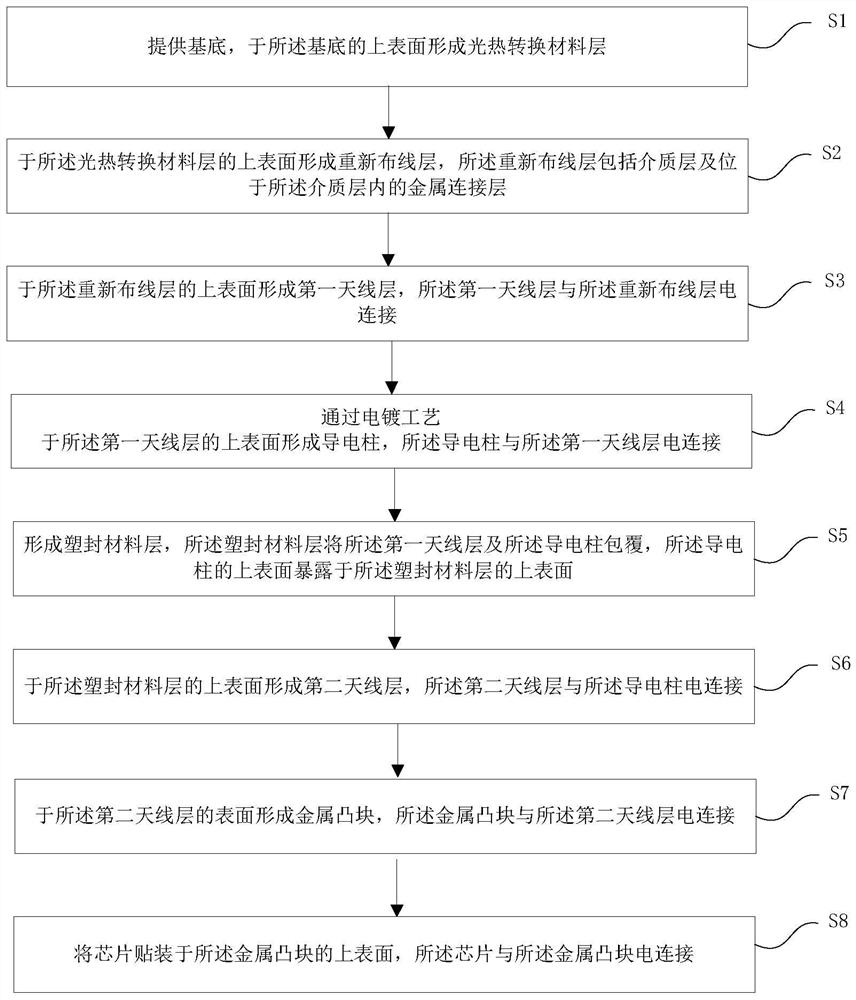

[0052] Such as figure 1 As shown, the present invention provides a kind of preparation method of semiconductor package structure, and described preparation method comprises steps:

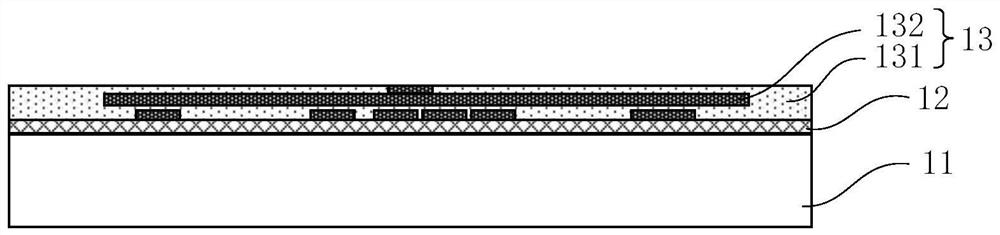

[0053] S1: providing a substrate 11, forming a light-to-heat conversion material layer 12 on the upper surface of the substrate 11;

[0054] S2: Form a rewiring layer 13 on the upper surface of the light-to-heat conversion material layer 12, the rewiring layer 13 includes a dielectric layer 131 and a metal connection layer 132 located in the dielectric layer 131, specifically as figure 2 shown;

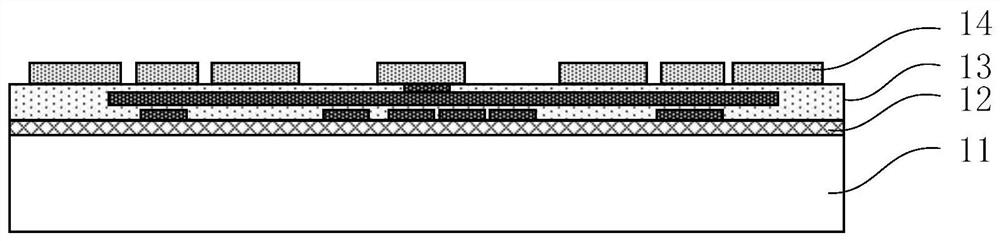

[0055] S3: Form the first antenna layer 14 on the upper surface of the rewiring layer 13, the first antenna layer 14 is electrically connected to the rewiring layer 13 (more precisely, it is electrically connected to the metal connection layer 132 ), specifically as image 3 shown;

[0056] S4: Form a conductive column 15 on the upper surface of the first antenna layer 14 through an electroplating pro...

Embodiment 2

[0079] Such as Figure 12As shown, the present invention also provides a semiconductor packaging structure, which can be prepared based on the preparation method of the first embodiment, so the description of the relevant structural layers in the first embodiment is fully applicable to this embodiment. Specifically, the semiconductor package structure includes a substrate 11, a light-to-heat conversion material layer 12, a rewiring layer 13, a first antenna layer 14, a conductive column 15, a plastic packaging material layer 16, a second antenna layer 17, a metal bump 18 and chip 19; the light-to-heat conversion material layer 12 is located on the upper surface of the substrate 11; the rewiring layer 13 is located on the upper surface of the light-to-heat conversion material layer 12, and the rewiring layer 13 includes a dielectric layer 131 and The metal connection layer 132 located in the dielectric layer 131; the first antenna layer 14 is located on the upper surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com