Meshed porous electric heating material for built-in porous heater and manufacturing method thereof

A technology for reticulated porous and electrothermal materials, which is applied in heating element materials, electrothermal devices, ohmic resistance heating, etc., can solve the problem that reticulated porous electrothermal materials cannot be prepared by conventional methods, and the electrothermal performance and formability are not examined. Small space and other problems, to achieve the effect of easy molding, high resistivity, high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

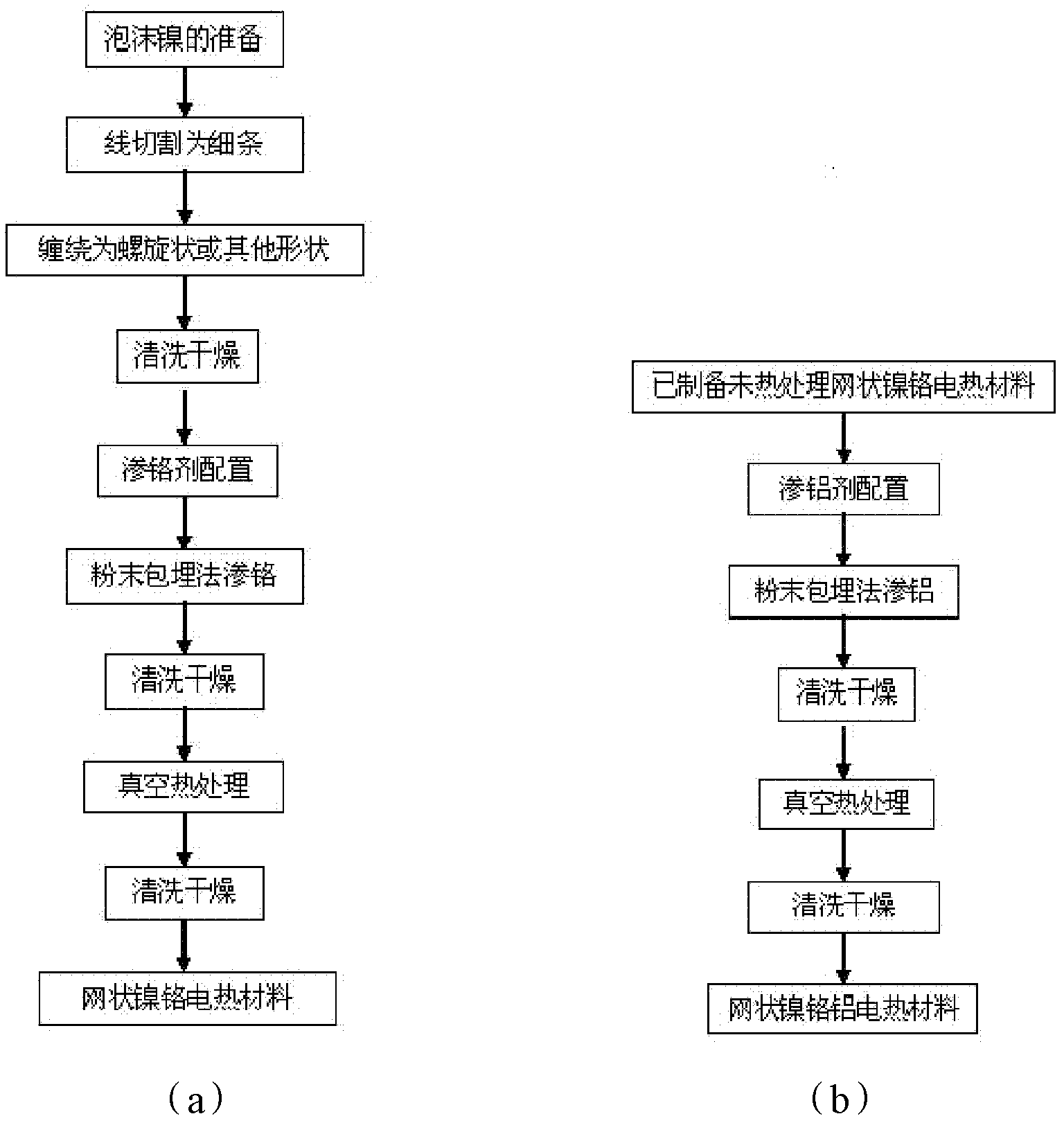

[0024] 1. Preparation of mesh porous nickel-chromium alloy electric heating material:

[0025] 1. Preparation and processing of nickel foam board

[0026] According to the internal space size and technical index requirements of the foam heater, determine the specifications of the foamed nickel plate through calculation, that is, surface density, pore size, thickness, porosity, etc., determine the apparent resistivity of the foamed nickel, and select a good quality foamed nickel plate . CNC wire cutting machine is used to process it into thin strips of the required size. During the cutting process, it is necessary to ensure that the nickel foam plate remains flat to ensure the uniformity of the size of the strip-shaped nickel foam; tap water is used as the cutting fluid, and nickel foam should be avoided as much as possible. Contamination, manual feeding, increased cutting rate. After the nickel foam is cut, wind it into a spiral shape, then add it to the boiling water contai...

Embodiment 1

[0045] Preparation of mesh porous nickel-chromium alloy electrothermal material with chromium mass fraction of 20%:

[0046] The internal size of the built-in porous heater is only Φ15×25mm, and the resistance of the mesh porous electric heating material in this space should reach 36.5±3.5Ω. The selected area density is 320g / m 2 1. A nickel foam plate with a pore diameter of 110PPI, a porosity of 97.6%, and a size of 1000mm×500mm×1.5mm has a resistivity of about 8.66μΩ.m. It is processed into a thin strip of 1000mm×1.2mm×1.5mm by a CNC wire cutting machine, and then wound into a spiral shape on a thin ceramic tube of Φ1.0mm, with a pitch of 0.5mm and a diameter of 1.0mm. The total length of nickel foam is about 220mm. Clean and dry, weigh and measure the resistance, the resistance value is about 4.5~5.0Ω.

[0047] Chromizing at 1000°C. The penetrating agent used is composed of 1200-mesh high-purity alumina powder, 300-mesh high-purity chromium powder and analytically pure ...

Embodiment 2

[0050] Preparation of mesh-like porous nickel-chromium-aluminum alloy electrothermal material with chromium mass fraction of 20% and aluminum mass fraction of 5%:

[0051] On the basis of Example 1, the mesh porous nickel-chromium alloy sample without vacuum heat treatment after solid-phase chromizing is placed in the aluminizing agent for aluminizing, and the used infiltrating agent consists of 1200 mesh high-purity alumina powder, chemical Pure aluminum-nickel alloy powder and analytically pure ammonium chloride were mixed and ground thoroughly, the mass ratio was 82:15:3, and the basic operation was the same as that in Example 1. Insulate at 750°C for 30 minutes, wash and dry the sample after cooling, and weigh it; calculate the aluminum mass fraction to be 5-6%, measure the resistance and size, the resistance value is about 15-19Ω, and the calculated resistivity is 33-37μΩ.m; then Put the aluminized sample into a vacuum furnace with a vacuum degree of 5×10-3Pa, raise the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com