Water-based electrothermal coating and preparation method thereof

An electrothermal coating, water-based technology, applied in the direction of coating, etc., can solve the problems of affecting the service life of the coating, small contact area, affecting the electrical conductivity of the coating, etc., to achieve improved utilization efficiency, high infrared radiation rate, and superior electrothermal performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

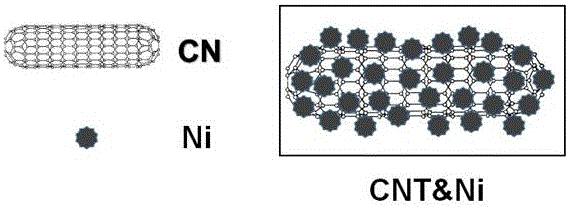

[0036] In a typical embodiment, the preparation method of the metal nickel-wrapped carbon nanotube composite powder may include the following steps:

[0037] Step 1: adding the carbon nanotube material raw material into a nitric acid solution with a concentration of 0.001-10 mol / liter, refluxing at 100-140° C. for 1-24 hours, and then filtering, washing the filtrate until neutral, and collecting it for later use;

[0038] Step 2: Gradually add the product obtained in Step 1 to a 1 mol / L nickel salt solution under high-speed stirring, mix and stir for 30-60 minutes, then filter, wash the filtrate with deionized water, and collect the filtrate for later use ;

[0039] Step 3: adding the product obtained in step 2 to the KBH with a concentration of 5 moles / liter 4 In the solution, in an ultrasonic dispersion environment, reduce for 20 minutes, reduce the adsorbed nickel ions to simple nickel, then filter, wash the filter out with deionized water, and collect the filtrate for lat...

Embodiment 1

[0048] Weigh raw materials according to the following formula (if not specified below, all refer to weight percentage):

[0049] Modified water-based acrylic resin 50%;

[0050] Leveling agent 1.2%;

[0051] Defoamer 0.1%

[0052] Co-solvent 1%

[0053] Carbon nanotube composite powder of nickel metal 10%;

[0054] Polyacrylic Grinding Resin 2%

[0055] water balance

[0056] Using the modified water-based water-based acrylic acid dispersion as the matrix resin, calculate the proportion according to the metering ratio, and slowly add the additive and the carbon nanotube composite powder wrapped in metal nickel into the collective resin under the stirring of the high-speed disperser, and at the same time add the dispersion agent, the stirring speed is 2000 rpm, and the stirring time is 30 minutes. Finally, the remaining amount of water is added to adjust to a suitable viscosity, and the water-based electric heating coating can be obtained after standing still for defoamin...

Embodiment 2

[0057] Example 2: The difference between this example and Example 1 is that the addition of the composite powder of metal nickel-wrapped carbon nanotubes is 20%, the sheet resistance of the coating after film formation is 120Ω / sq, the adhesion is grade 1, and the hardness is 2H .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com