Textile material with flexible electric heating function, preparation method and application of textile material

A technology of textile materials and flexible electricity, which is applied in the field of preparation of textile materials with flexible electrical heating function, can solve the problems of poor fit between textile materials and clothing, large volumes of heating wires and heating pipes, and inflexibility of graphene materials. and other problems, to achieve good application prospects, improve wearability and comfort, and good fit with the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

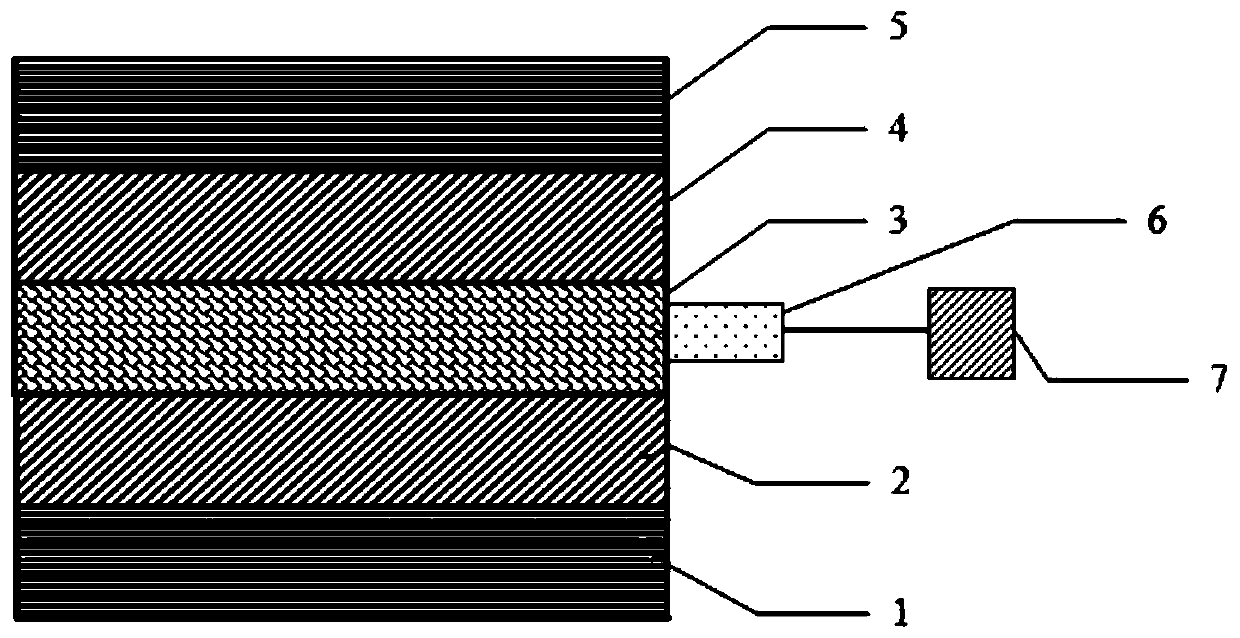

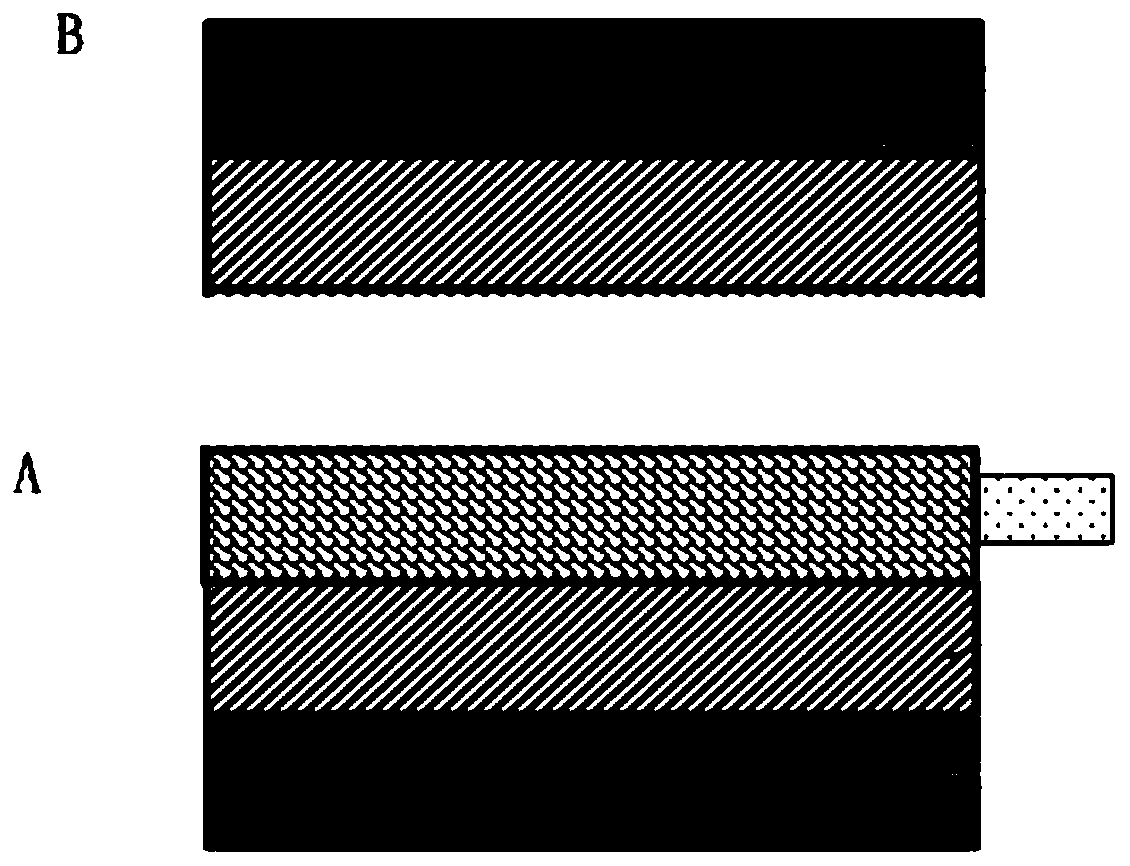

[0044] Such as figure 1 As shown, the textile material with elastic electric heating function is in a laminated structure, from bottom to top are the first textile material layer 1, the first flexible insulating layer 2, the flexible heating layer 3, the second flexible insulating layer 4, and the second Textile material layer 5. The flexible heating layer 3 is electrically connected to one end of the electrode 6 , and the other end of the electrode 6 is connected to a power source 7 .

[0045] The material of the flexible heating layer is liquid metal GaInSn.

[0046] The flexible heating layer is electrically connected to one end of the copper electrode, and the other end of the copper electrode is connected to a voltage source.

[0047] The first textile material layer 1 is elastic cotton cloth with a thickness of 0.25-1.0 mm, 0.5 mm in this embodiment.

[0048] The first textile material layer 5 is elastic cotton cloth with a thickness of 0.25-1.0 mm, 0.5 mm in this emb...

Embodiment 2

[0062] In this embodiment, the structure of the textile material with elastic electric heating function is basically the same as that in Embodiment 1, except that the material of the flexible heating layer is liquid metal GaInSn doped with graphene.

[0063] In this embodiment, the preparation method of the textile material with elastic electric heating function is basically the same as that of Embodiment 1, the difference is that in process A, the graphene is heated during the preparation of the liquid metal alloy solution to obtain a uniform and stable doped A liquid metal alloy solution of graphene, filling the liquid metal alloy solution doped with graphene in a template.

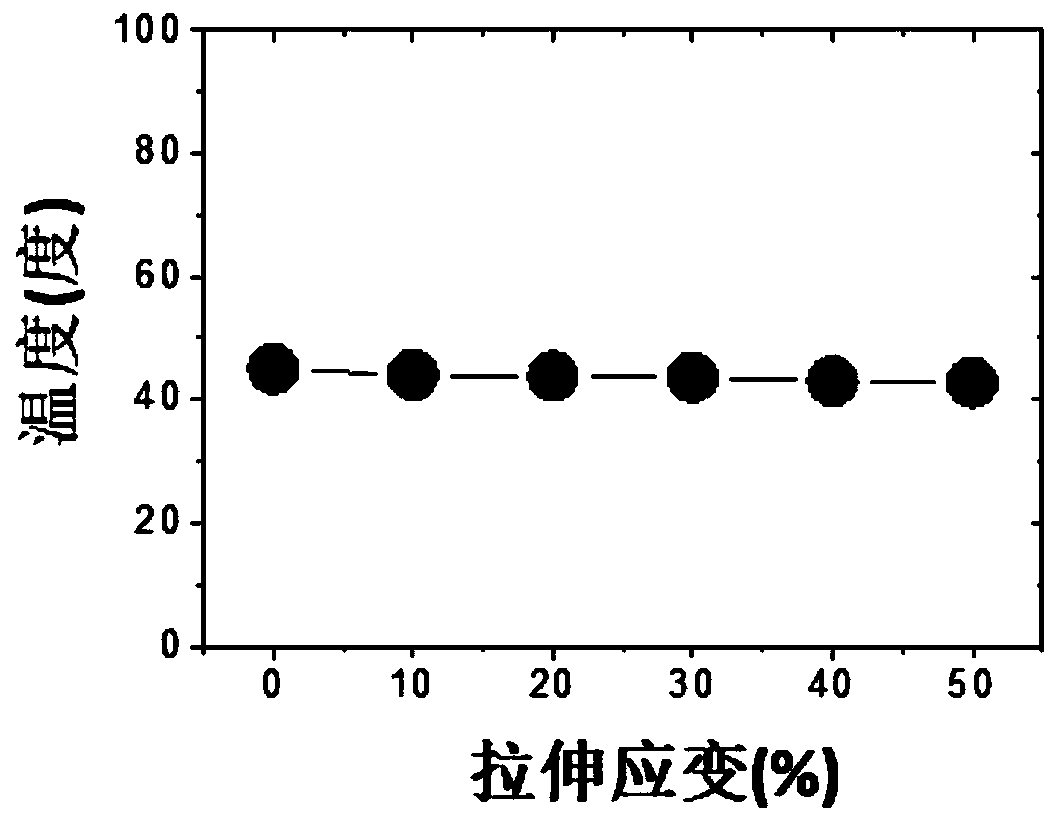

[0064] In this embodiment, a commonly used voltage source with a voltage of 5V and a power of 12W is selected, the control switch of the voltage source is turned on, the flexible heating layer is energized, the liquid metal generates heat, and the temperature of the textile material prepared above increa...

Embodiment 3

[0067] In this embodiment, the structure of the textile material with elastic electric heating function is basically the same as that of Embodiment 1, except that the first flexible insulating layer is polydimethylsiloxane doped with graphene, and its thickness is 0.20 mm.

[0068] In this embodiment, the preparation method of the textile material with elastic electric heating function is basically the same as that of Embodiment 1, the difference is that in process A, the first flexible insulating layer material is polydimethylsiloxane doped with graphene Alkanes, the thickness is 0.20mm.

[0069] In this embodiment, a commonly used voltage source with a voltage of 5V and a power of 12W is selected, the control switch of the voltage source is turned on, the flexible heating layer is energized, the liquid metal generates heat, and the temperature of the textile material prepared above increases through heat conduction. Moreover, in this embodiment, the first flexible insulating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com