Aqueous heat dissipation coating and preparation method thereof

A technology of heat-dissipating coatings and water-based dispersions, applied in epoxy resin coatings, coatings, etc., can solve the problems of small contact area and large contact thermal resistance, achieve high infrared emissivity, reduce interface thermal resistance, and improve dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

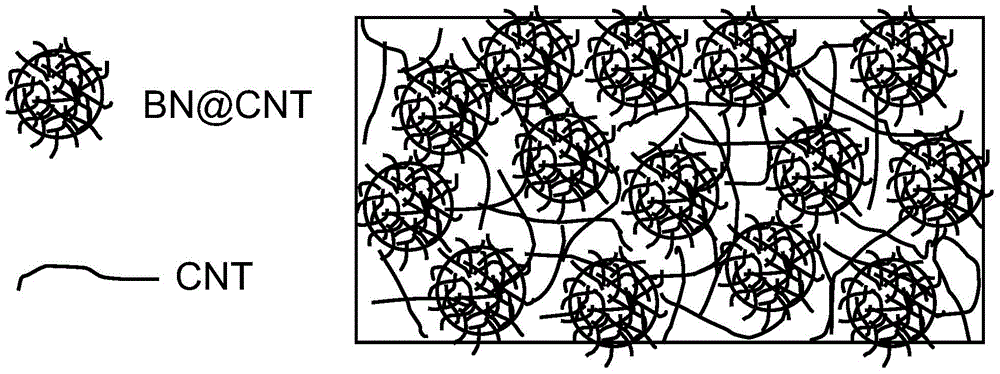

[0044] In a typical embodiment, the preparation method of the nano-carbon-wrapped boron nitride composite powder may include the following steps:

[0045](1) Add the nano-carbon material raw material into the nitric acid solution with a concentration of 2-8 M, reflux at 100-140°C for 1-24 h, then filter, wash the filtrate until neutral, and collect it for later use;

[0046] (2) Disperse the boron nitride powder in an anhydrous solvent, add an amino coupling agent accounting for 1-30% of the weight of the boron nitride powder, mix and stir for 1-24h, then stir at 70-100°C for 30min-1h , then filter, and collect the filtrate for subsequent use;

[0047] (3) Disperse the product obtained in step (1) in water, gradually add the product obtained in step (2) under high-speed stirring, mix and stir for 10min-2h, then filter, collect the filtrate, and vacuum dry at 60-100°C 1-6h, obtain nano-carbon material wrapped boron nitride composite powder;

[0048] In addition, the aforement...

Embodiment 1

[0061] Weigh raw materials according to the following formula (if not specified below, all refer to weight percentage):

[0062] Acrylic modified water-based epoxy resin 20%;

[0063] Auxiliary 3%;

[0064] Carbon nanotube-wrapped boron nitride composite powder 1%;

[0065] Carbon nanotubes 1%;

[0066] Polyacrylic Grinding Resin 2%

[0067] water balance. The aforementioned additives include defoamers, leveling agents, co-solvents, etc. commonly used in the industry.

[0068] The acrylic modified epoxy resin aqueous dispersion is used as the matrix resin, and the ratio is calculated according to the metering ratio. The matrix resin, carbon nanotubes, polyacrylic acid grinding resin, defoamer BYK021, etc. are ground and dispersed in a grinding disperser for 8 hours. Nano carbon material dispersion slurry. Then, under stirring by a high-speed disperser, slowly add the remaining additives and carbon nanotube-wrapped boron nitride composite powder into the carbon nanotube d...

Embodiment 2

[0069] Example 2: The difference between this example and Example 1 lies in that the addition amount of carbon nanotubes is 2%, the infrared radiation coefficient of the coating after film formation is 0.95, the thermal conductivity is 1.2 W / m K, and the hardness is 2H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com