Selective absorbing coating

An absorption coating, selective technology, applied in the field of solar thermal, which can solve the problems of low heat loss and high absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

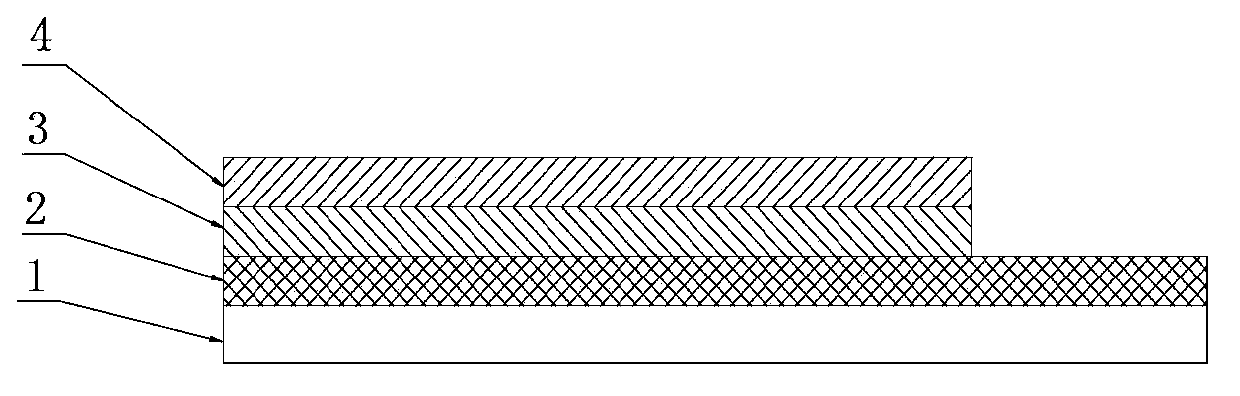

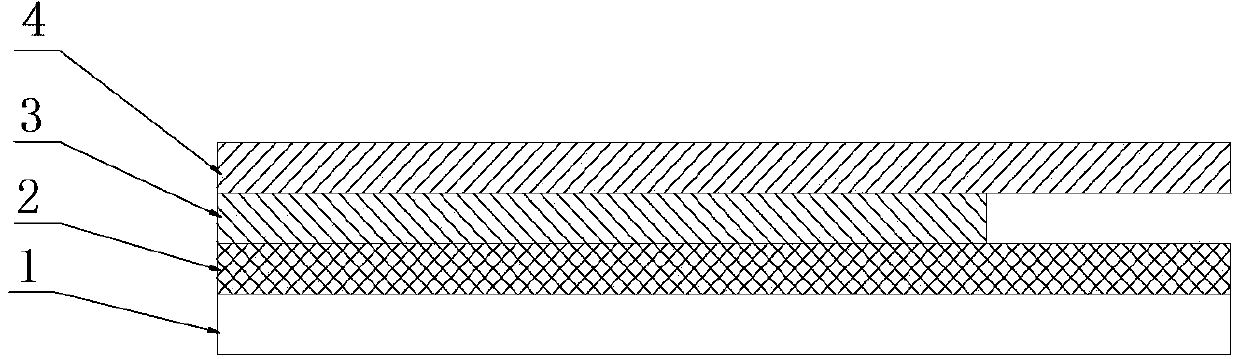

Embodiment 1

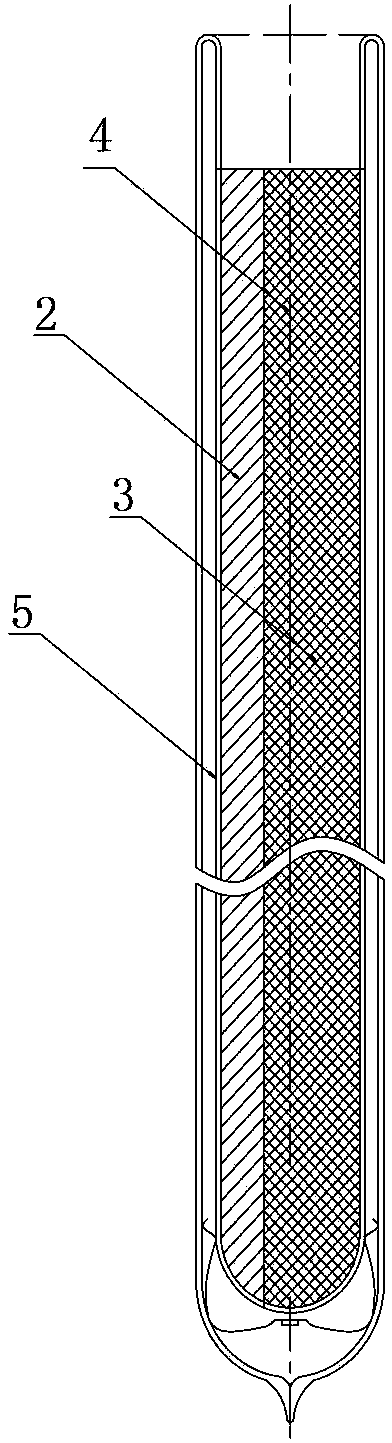

[0038] image 3Shown is the embodiment that the selective absorbing coating of the present invention is used on the all-glass vacuum solar collector tube, the glass inner tube 5 of the all-glass vacuum solar collector tube serves as the substrate 1 of the selective absorbing coating, and the metal Layer 2, absorber layer 3, surface dielectric layer 4. The metal layer 2 is attached to the glass inner tube 5 of the all-glass vacuum solar heat collector tube, and the material is copper, and the thickness of the film layer is 100nm. The absorbing layer 3 is made of stainless steel aluminum nitride, and is attached to the metal layer 2 where it can be irradiated or directly irradiated by sunlight. The molar ratio of metal atoms to nitrides or oxides is 0-1, and the film thickness is 100nm; The surface dielectric layer 4 covers the absorbing layer 3 and the exposed metal layer 2, and is made of aluminum nitride with a film thickness of 50 nm. In this embodiment, in order to increa...

Embodiment 2

[0041] Figure 4 It is the application of the selective absorption coating of the present invention on the all-glass heat pipe vacuum solar collector tube 6 . The inner tube of the all-glass heat pipe vacuum solar collector tube 6 acts as a substrate 1, and the bonding layer, metal layer 2, absorber layer 3, and surface dielectric layer 4 are arranged on the outer wall of the inner tube of the all-glass heat pipe vacuum solar collector tube 6. The adhesive layer is made of aluminum and aluminum nitride or oxide, and the film thickness is 20nm; the metal layer 2 is attached to the adhesive layer, and the material is aluminum, and the film thickness is 100nm; the absorption layer 3 is attached to the metal layer 2 The area that can be irradiated or directly irradiated by sunlight is made of aluminum and aluminum nitride or oxide, the metal molar ratio is 0-1, multi-layer arrangement, and the film thickness is 150nm; the surface dielectric layer 4 is set on the absorption layer 3...

Embodiment approach 3

[0043] Figure 5 , Figure 6 It is the application of the selective absorption coating of the present invention on the glass-metal sealed heat pipe 9 . The metal fins 8 of the glass-metal sealed heat pipe 9 act as the substrate 1 of the selective absorption coating, the bonding layer, the metal layer 2, the absorption layer 3, and the surface dielectric layer 4 are arranged on the metal fins 8, and the glass-metal The getter 7 of the metal-sealed heat pipe 9 is arranged on the metal fin 8 . The adhesive layer is made of silicon and silicon nitride or oxide, and the film thickness is 10nm; the metal layer 2 is attached to the adhesive layer, and the material is copper, and the film thickness is 60nm; the absorption layer 3 is attached to the metal layer 2. The side facing the sun is made of stainless steel, the molar ratio of metal atoms to nitrides or oxides is 0-1, and the thickness of the film layer is 100nm; the surface dielectric layer 4 is arranged on the absorption lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com