A kind of graphene composite material and preparation method thereof for fuel-saving ambulance

A composite material and graphene technology, applied in the direction of fuel, mechanical equipment, charging system, etc., can solve the problem of not very obvious fuel saving effect, achieve low production cost, reduce wear and tear, and achieve high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A graphene composite material for a fuel-saving ambulance, comprising: 5% graphene material, 85% mineral powder, 5% additive, and 5% binder. Wherein graphene or graphene oxide powder is prepared by mechanical exfoliation; mineral powder contains iron, zinc, copper, cobalt; additive contains polyisobutylene amine, n-butanol; binder contains polyvinyl alcohol, the above bonding The agent contained 0.03% polydimethylsiloxane and 0.07% cobalt acetylacetonate hydrate.

[0050] A kind of preparation method of the graphene composite material that is used for fuel-saving ambulance, its concrete steps are as follows:

[0051] (1) Weigh the negative ion powder raw material, mix it with graphene or graphene oxide evenly, grind it through a grinder for 5 minutes to form a fine sand powder, separate the heavy metal through magnetic separation, and sieve to obtain the graphene material. The above negative ion The body includes the following raw materials in parts by weight: 20 parts...

Embodiment 2

[0057] A graphene composite material for a fuel-saving ambulance, comprising: 5% graphene material, 85% mineral powder, 5% additive, and 5% binder. Wherein graphene or graphene oxide powder is prepared by mechanical exfoliation; mineral powder contains iron, zinc, copper, cobalt; additive contains polyisobutylene amine, n-butanol; binder contains polyvinyl alcohol, the above bonding The agent included 0.05% polydimethylsiloxane and 0.05% cobalt acetylacetonate hydrate.

[0058] The preparation method of the graphene composite material in this embodiment is consistent with the steps in Example 1, and a block-shaped graphene composite material is obtained.

Embodiment 3

[0060] The raw material of graphene composite material in this embodiment is consistent with embodiment 2.

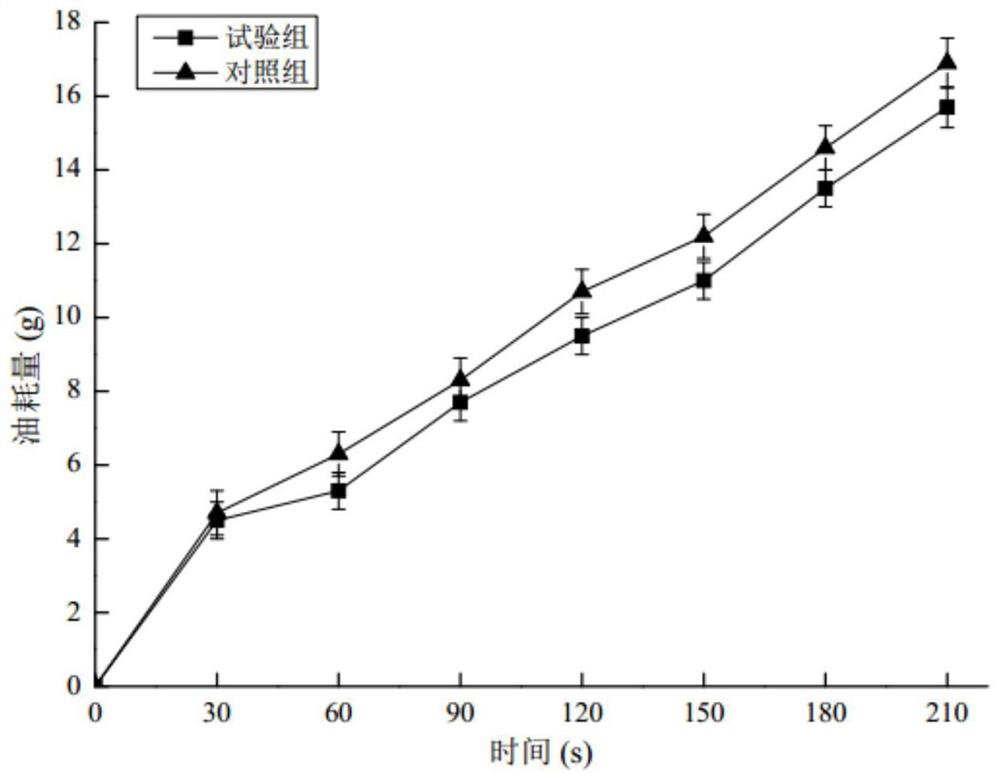

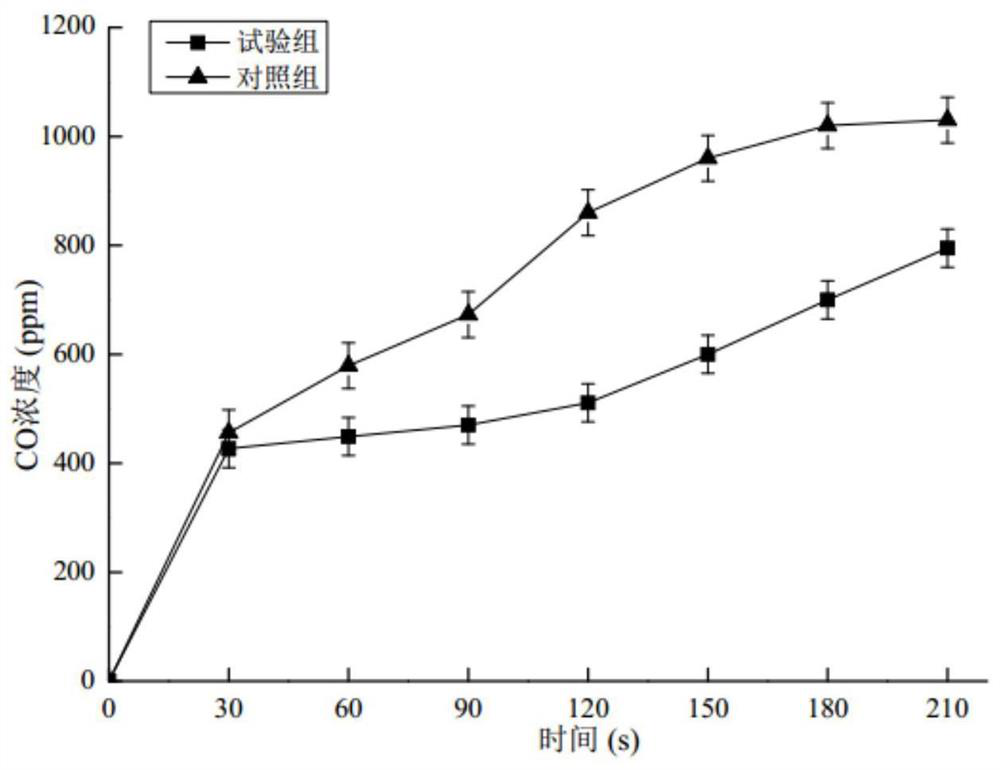

[0061] The preparation method of graphene composite material in the present embodiment is consistent with other steps in embodiment 2, difference only is: in step (1), add grinding aid, its addition is 0.03% of negative ion powder weight, this grinding aid It includes propylene oxide and 2-mercaptobenzimidazole, and its weight ratio is 2.3:0.7. When the two are added to the grinding process, the mechanical energy is used to combine with the surface layer of the graphene structure, which can not only improve the infrared radiation rate of graphene, but also link Part of the negative ions stay on the surface of graphene, which weakens the link between negative ions and graphene, and the negative ions are released more easily, which shortens the time required for the release of negative ions after the block structure contacts gasoline to improve oil quality, and achieves fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com