Thermal insulation coating for building exterior walls and preparation method thereof

A technology for heat insulation and building exterior walls, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of thermal insulation characteristics to be improved, complicated process, and many steps in the production process, and achieve excellent thermal insulation performance, Increase the microporosity and improve the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of this coating is as follows:

[0038] Add silicone-acrylic emulsion, modified airgel, floating beads, reinforcing filler, Glauber's salt and additives into the reaction kettle in succession, first stir at 300r / min for 40-50min, and then grind for 10-12min through a high-speed dispersing grinder. Then stir at 3000r / min for 25-30min to obtain the thermal insulation coating.

Embodiment 1

[0040] A thermal insulation coating for building exterior walls, made of the following raw materials in parts by weight: 50 parts of silicon-acrylic emulsion, 18 parts of modified airgel, 7 parts of floating beads, 3 parts of reinforcing filler, 2 parts of Glauber's salt, and 0.6 parts of additives share;

[0041] The thermal insulation coating is made by the following steps:

[0042] Add silicone-acrylic emulsion, modified airgel, floating beads, reinforcing filler, Glauber's salt and additives into the reaction kettle in succession, first stir at 300r / min for 40min, then grind for 10min with a high-speed dispersing grinder, then grind at 3000r / min Stir for 25 minutes to obtain a thermal insulation coating.

Embodiment 2

[0044] A thermal insulation coating for building exterior walls, made of the following raw materials in parts by weight: 55 parts of silicone acrylic emulsion, 20 parts of modified airgel, 8 parts of floating beads, 3.5 parts of reinforcing filler, 2.5 parts of Glauber's salt, and 0.8 parts of additives share;

[0045] The thermal insulation coating is made by the following steps:

[0046] Add silicone-acrylic emulsion, modified airgel, floating beads, reinforcing filler, Glauber's salt and additives into the reaction kettle in proportion, first stir at 300r / min for 45min, then grind for 11min through a high-speed dispersing grinder, and then 3000r / min Stir for 28 minutes to obtain a thermal insulation coating.

PUM

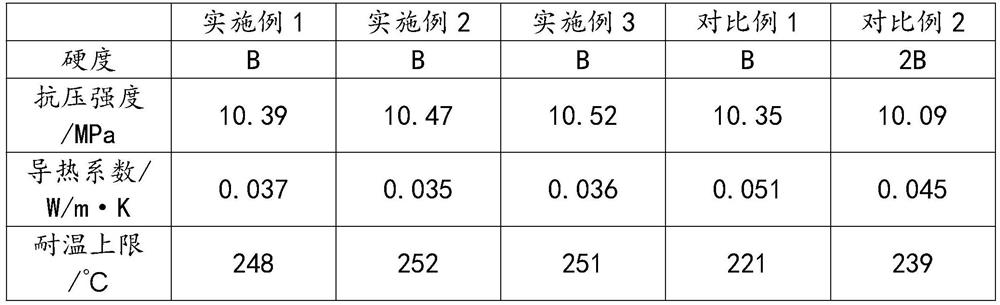

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com