A kind of preparation method of coordination cross-linked rubber containing crystal water metal salt

A technology of coordination cross-linking and metal salt, applied in the field of coordination and cross-linking of rubber, can solve the problem of deteriorating compatibility between metal salts and rubber, high activation energy of coordination cross-linking reaction, uneven coordination and cross-linking reaction, etc. problems, to achieve the effects of improving wettability and blending uniform dispersion, increasing melting and ionization probability, and improving coordination and crosslinking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

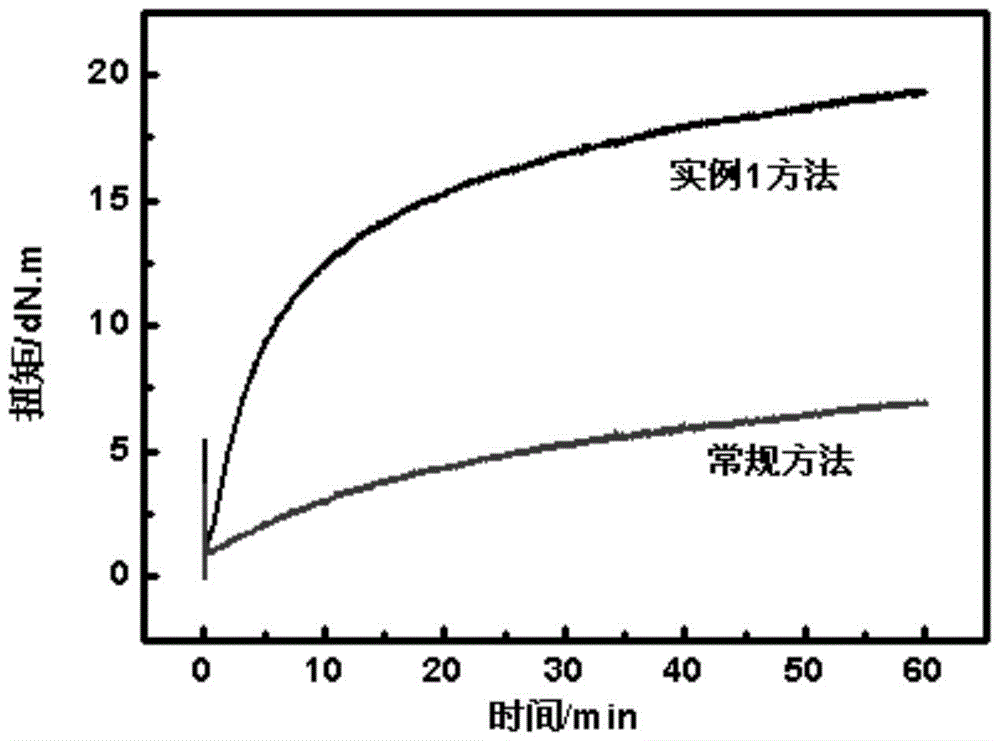

Embodiment 1

[0033] (1) Formula

[0034]

[0035]

[0036] (2) steps

[0037] a. Low-temperature mixing: put acrylate-butadiene rubber into the internal mixer, masticate at 40°C for 1 min; then, add copper sulfate pentahydrate, silane coupling agent and octyl phthalate according to the formula, Mix evenly at 50°C to obtain low temperature mixed rubber;

[0038] b. High-temperature mixing: In the open mill, mix the obtained low-temperature rubber mixture at 110°C for 8 minutes, then add calcium oxide, continue mixing evenly, and obtain high-temperature rubber mixture;

[0039] c. Coordination cross-linking: Send the obtained high-temperature mixed rubber into the vulcanization equipment, preheat at 180°C for 1 min under normal pressure, then vulcanize at 10 MPa for 34 min, discharge, and cool to obtain a coordination cross-linked rubber.

[0040]Preparation of the comparison sample: according to the conventional method, that is, the method reported in the patent ZL200410025013.0.

...

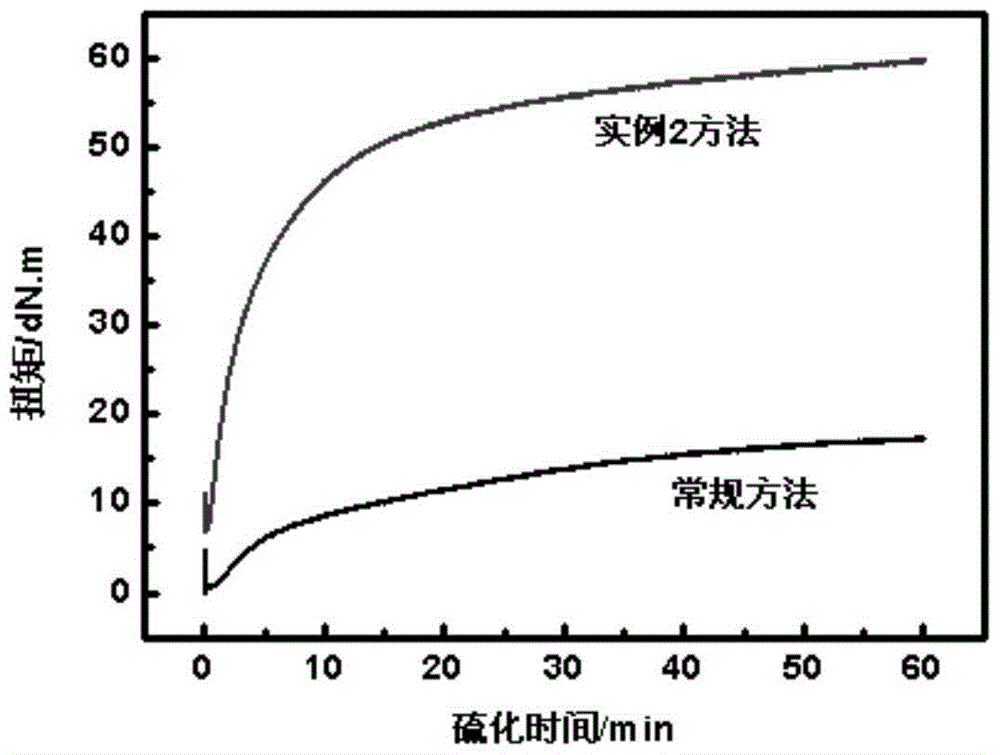

Embodiment 2

[0048] (1) Formula

[0049]

[0050] (2) steps

[0051] a. Low-temperature mixing: put nitrile rubber into the open mill, and masticate at 35°C for 3 minutes; then, according to the formula, add aluminum sulfate octadecahydrate, white carbon black, aluminate coupling agent and liquid nitrile, Mix evenly at 45°C to obtain low temperature mixed rubber;

[0052] b. High-temperature mixing: In an open mill, mix the obtained low-temperature rubber mixture at 120°C for 5 minutes, then add zinc oxide, continue mixing evenly, and obtain a high-temperature rubber mixture;

[0053] c. Coordination cross-linking: send the obtained high-temperature mixed rubber into the vulcanization equipment, preheat at 200°C for 1.5 minutes under normal pressure, then vulcanize at 10 MPa for 25 minutes, discharge, and cool to obtain coordination cross-linked rubber.

[0054] Preparation of the comparison sample: prepared according to the conventional method, that is, the method reported in the pat...

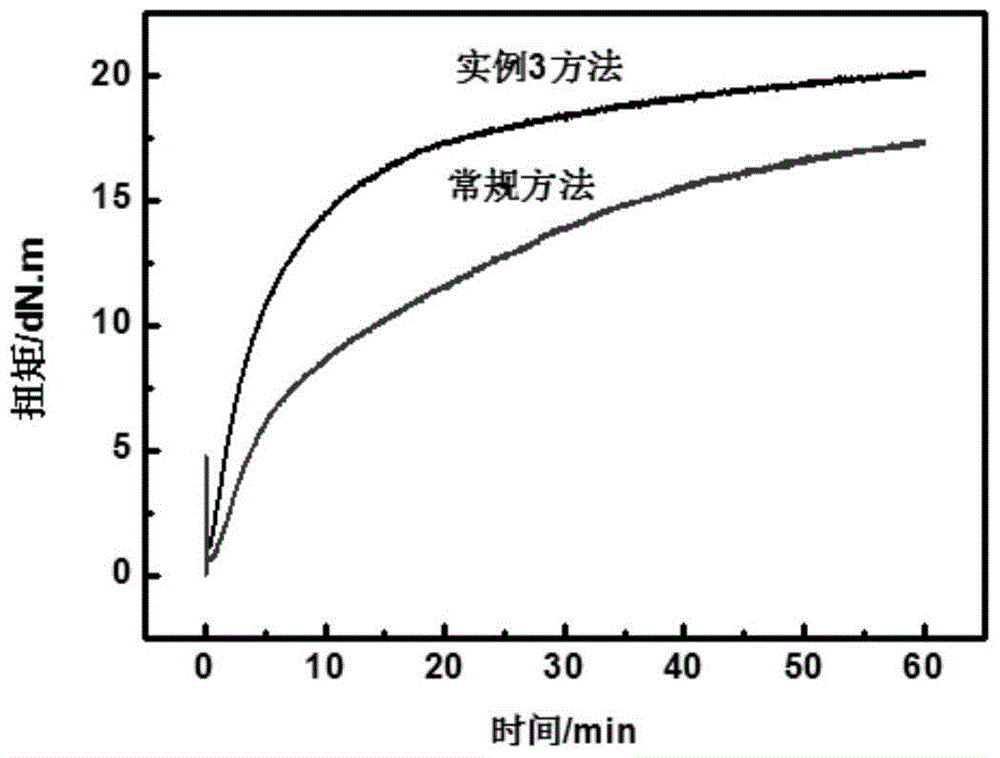

Embodiment 3

[0063] (1) Formula

[0064] Nitrile rubber 100g

[0065] Cerium Sulfate Tetrahydrate 30g

[0067] (2) steps

[0068] a. Low-temperature mixing: put nitrile rubber into the open mill, and masticate at 35°C for 2 minutes; then, add cerium sulfate tetrahydrate according to the formula, and mix evenly at 45°C to obtain low-temperature compounded rubber;

[0069] b. High-temperature mixing: In the open mill, mix the obtained low-temperature rubber mixture at 115°C for 6 minutes, then add magnesium oxide, continue mixing evenly, and obtain a high-temperature rubber mixture;

[0070] c. Coordination cross-linking: send the obtained high-temperature mixed rubber into the vulcanization equipment, preheat at 175°C for 0.5 min under normal pressure, then vulcanize at 15 MPa for 27 min, discharge, and cool to obtain coordination cross-linked rubber.

[0071] Preparation of the comparison sample: prepared according to the conventional method, that is, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com