Complexing type nylon nucleating agent and compound containing nylon nucleating agent, and preparation methods thereof

A technology of nucleating agent and compound, which is applied in the field of complex nylon nucleating agent and its preparation, nylon compound containing the nylon nucleating agent and its preparation, can solve the problems of poor compatibility and difficulty in dispersibility, and achieve Increased crystallinity, increased nucleation sites, and weakened hydrogen bond forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

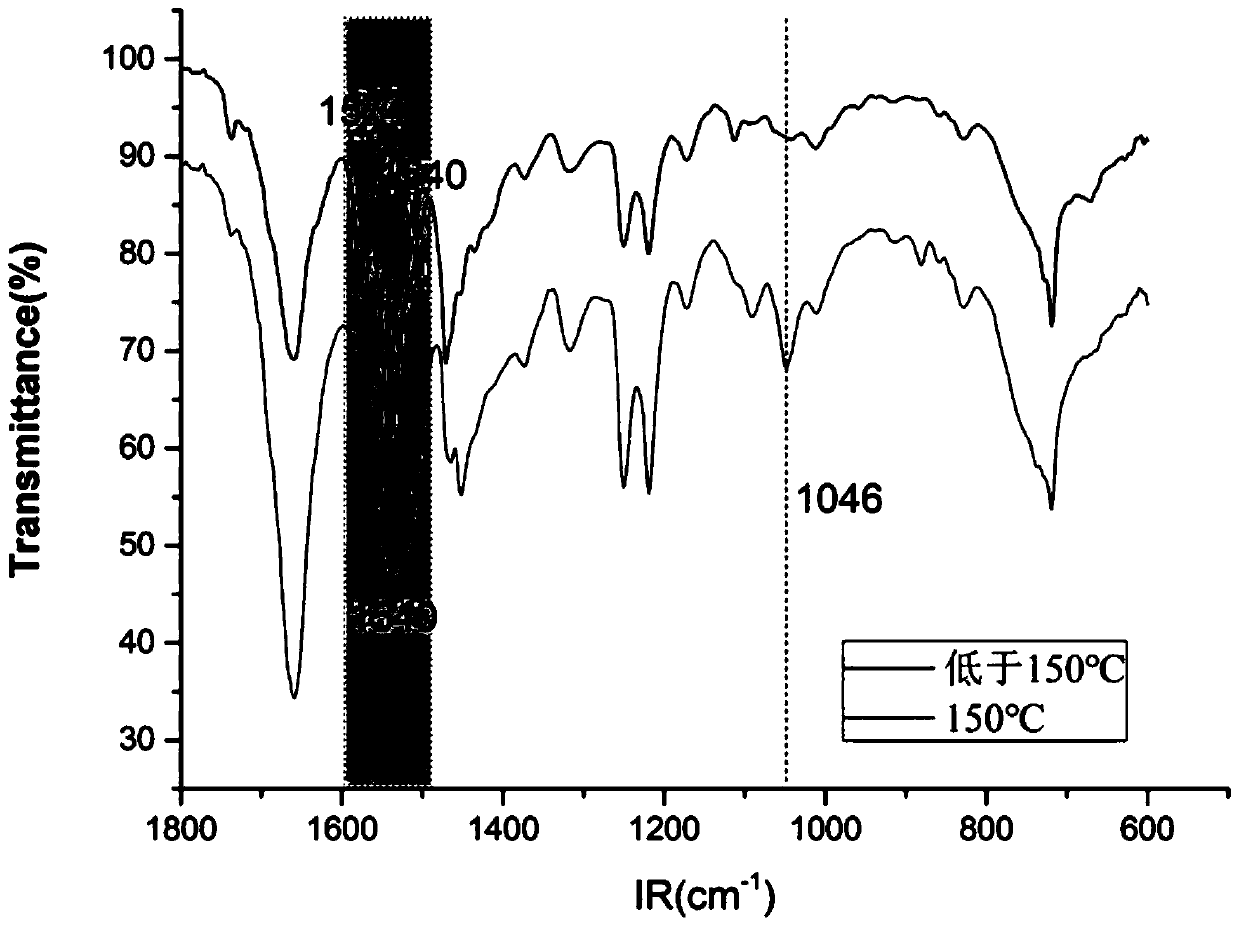

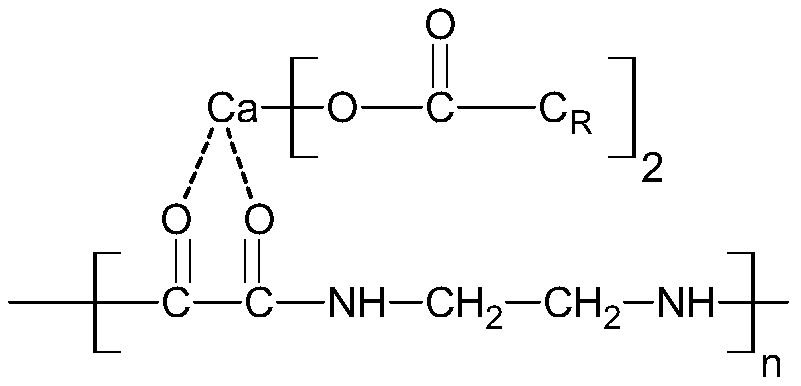

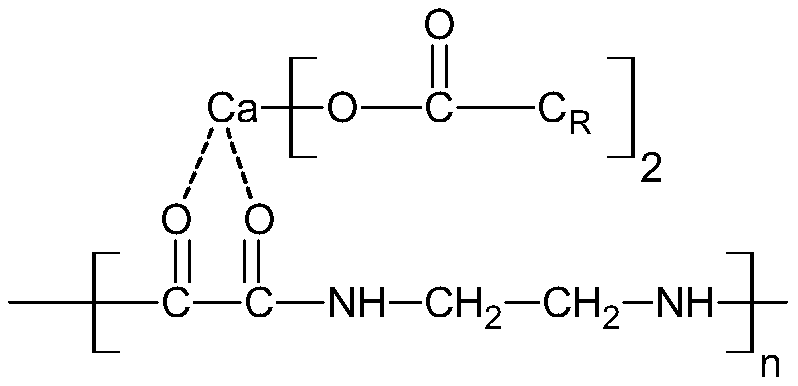

[0029] The complexed nylon nucleating agent of this embodiment is formed by the complexation of polyamide 22 and long carbon chain fatty acid calcium, and has the following formula (I) structure:

[0030]

[0031] In formula (I), R is 11-31, n≥2.

[0032] Preferably, the polyamide 22 has a molecular weight of 700.

[0033] Preferably, the long-chain fatty acid calcium is calcium montan cerate.

[0034] Further, the mass ratio of polyamide 22 to long-chain fatty acid calcium is 1:9.

[0035] The preparation method of the complex type nylon nucleating agent of the present embodiment comprises the following steps: adding polyamide 22 and long carbon chain fatty acid calcium to a high-speed mixer and mixing them evenly, and then adding the mixture to banburying Inside the machine, heat up to the set temperature and banbury for more than 10 minutes, then cool and discharge to obtain complex nylon nucleating agent.

[0036] Further, the set temperature is 120°C.

[0037] The ...

Embodiment 2

[0042] A kind of complex type nylon nucleating agent of this embodiment is formed by the complexation of polyamide 22 and long carbon chain fatty acid calcium, and has the following formula (I) structure:

[0043]

[0044] In formula (I), R is 11-31, n≥2.

[0045] Preferably, the polyamide 22 has a molecular weight of 1000.

[0046] Preferably, the long-chain fatty acid calcium is calcium montan cerate.

[0047] Further, the mass ratio of polyamide 22 to long-chain fatty acid calcium is 3:7.

[0048] The preparation method of the complex type nylon nucleating agent of the present embodiment comprises the following steps: adding polyamide 22 and long carbon chain fatty acid calcium to a high-speed mixer and mixing them evenly, and then adding the mixture to banburying Inside the machine, heat up to the set temperature and banbury for more than 10 minutes, then cool and discharge to obtain complex nylon nucleating agent.

[0049] Preferably, the set temperature is 130°C. ...

Embodiment 3

[0055] The complexed nylon nucleating agent of this embodiment is formed by the complexation of polyamide 22 and long carbon chain fatty acid calcium, and has the following structure of formula (I):

[0056]

[0057] In formula (I), R is 11-31, n≥2.

[0058] Preferably, the molecular weight of the polyamide 22 is 1200.

[0059] Preferably, the long-chain fatty acid calcium is calcium montan cerate.

[0060] Further, the mass ratio of polyamide 22 to long-chain fatty acid calcium is 5:5.

[0061] The preparation method of the complex type nylon nucleating agent of the present embodiment comprises the following steps: adding polyamide 22 and long carbon chain fatty acid calcium to a high-speed mixer and mixing them evenly, and then adding the mixture to banburying Inside the machine, heat up to the set temperature and banbury for more than 10 minutes, then cool and discharge to obtain complex nylon nucleating agent.

[0062] Preferably, the set temperature is 150°C.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com