A kind of high-strength nylon 6 filament based on one-step drafting process and preparation method thereof

A nylon, high-strength technology, applied in the field of high-strength nylon 6 filament and its preparation, can solve the problems of reduced fiber toughness, complicated preparation process, cumbersome solvent removal, etc., achieve high elongation at break, low initial modulus, and improve mechanical strength Effects on properties and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

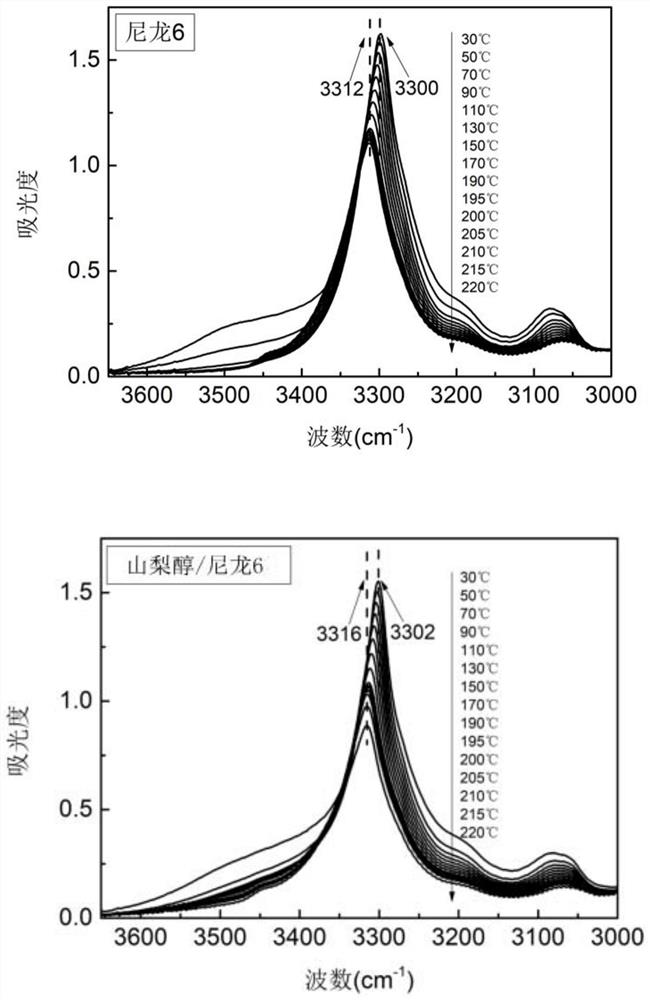

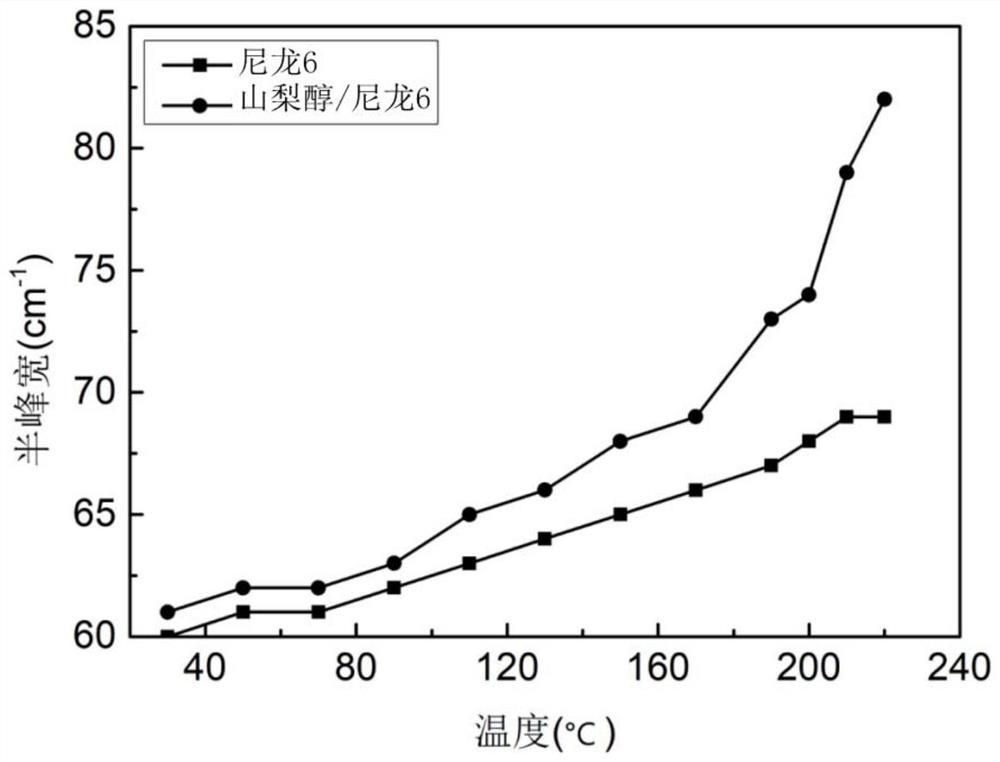

Method used

Image

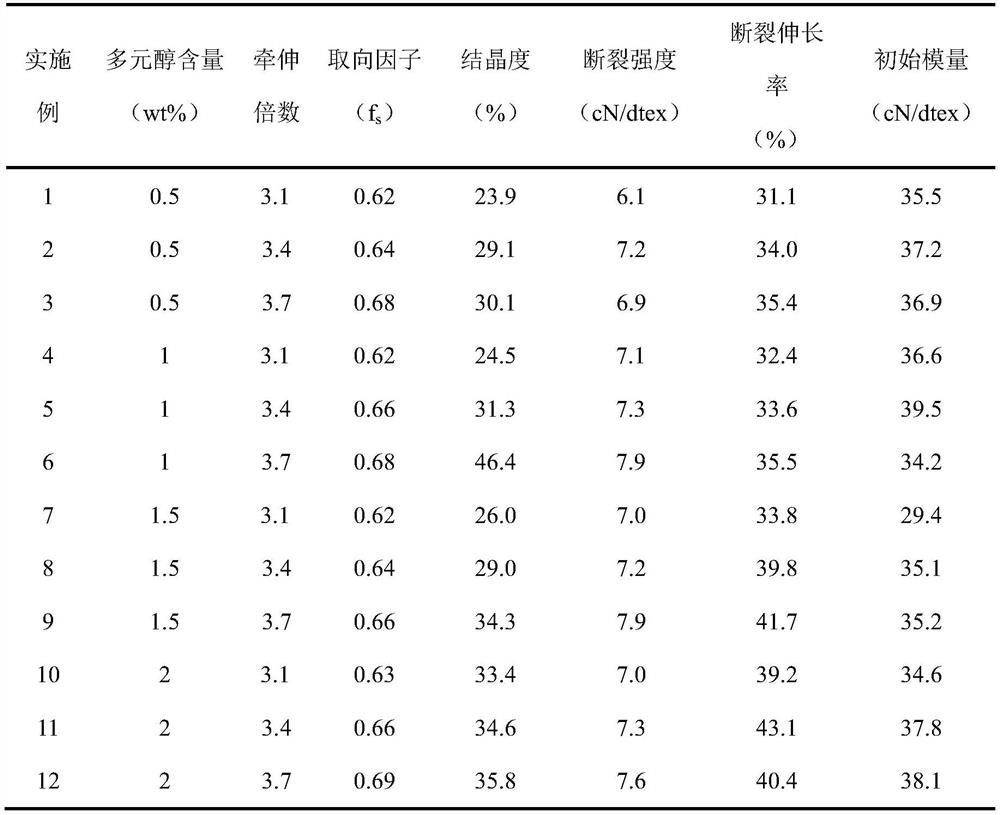

Examples

Embodiment 1

[0026] This embodiment provides a high-strength nylon 6 filament based on a one-step drawing process and a preparation method thereof, which specifically includes the following process steps:

[0027] Step 1: In parts by weight, take 90 parts of nylon 6 slices and place them in a vacuum drying oven at 100°C for 8 hours, then put them in a blast drying oven at 105°C for 5 hours, take 10 parts of solid mannitol and mix them with The nylon 6 slices were stirred evenly, and the mixed mannitol / nylon 6 was fed into the twin-screw extruder for melt blending. The temperatures in each zone of the twin-screw extruder were: 230°C for the first zone, 240°C for the second zone, 245°C for the third zone, The fourth zone is 245°C, the fifth zone is 245°C, the speed of the main machine is 5.8rpm, and the speed of the feeder is 4.7rpm. At the same time, the extruded melt is pelletized by the pelletizer to prepare mannitol / nylon 6 masterbatch;

[0028] Step 2: In parts by weight, mix 5 parts of...

Embodiment 2

[0030] This embodiment provides a high-strength nylon 6 filament based on a one-step drawing process and a preparation method thereof, which specifically includes the following process steps:

[0031] Step 1: In parts by weight, take 90 parts of nylon 6 slices and place them in a vacuum drying oven at 100°C for 8 hours, then put them in a blast drying oven at 105°C for 5 hours, take 10 parts of solid sorbitol and mix them with The nylon 6 slices are stirred evenly, and the mixed sorbitol / nylon 6 is fed into the twin-screw extruder for melt blending. The temperatures in each zone of the twin-screw extruder are: 230°C for the first zone, 240°C for the second zone, 245°C for the third zone, The fourth zone is 245°C, the fifth zone is 245°C, the speed of the main machine is 5.8rpm, the speed of the feeder is 4.7rpm, and the extruded melt is pelletized by the pelletizer to prepare sorbitol / nylon 6 masterbatch;

[0032] Step 2: In parts by weight, mix 5 parts of the masterbatch obta...

Embodiment 3

[0036] This embodiment provides a high-strength nylon 6 filament based on a one-step drawing process and a preparation method thereof, which specifically includes the following process steps:

[0037]Step 1: In parts by weight, take 90 parts of nylon 6 slices and place them in a vacuum drying oven at 100°C for 8 hours, then put them in a blast drying oven at 105°C for 5 hours, take 10 parts of solid pentaerythritol and mix them with nylon at room temperature 6. Stir the slices evenly, and feed the mixed pentaerythritol / nylon 6 blend into the twin-screw extruder for melt blending. The temperatures in each zone of the twin-screw extruder are: 230°C for the first zone, 240°C for the second zone, and 245°C for the third zone. , 245°C in the fourth zone, 245°C in the fifth zone, the speed of the main machine is 5.8rpm, the speed of the feeder is 4.7rpm, and the extruded melt is pelletized by the pelletizer to prepare pentaerythritol / nylon 6 masterbatch;

[0038] Step 2: In parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com