High infrared emitting electrothermal film based on graphene and preparation method of high infrared emitting electrothermal film

An infrared emission and graphene technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of affecting the practical effect of heating, film heat accumulation, and low heat radiation ratio, so as to reduce internal transmission loss and improve Radiation heat transfer ratio and the effect of enhancing the infrared radiation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

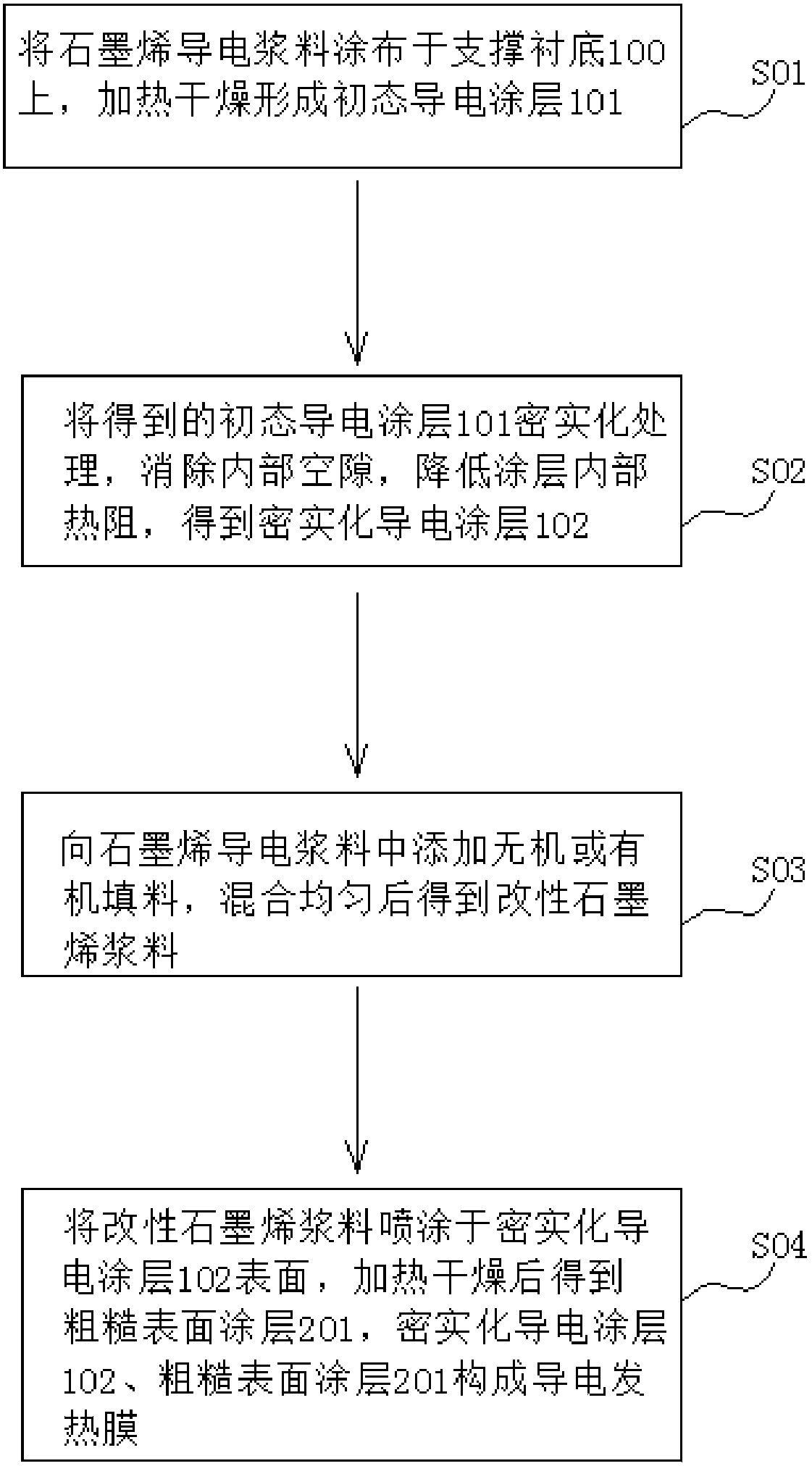

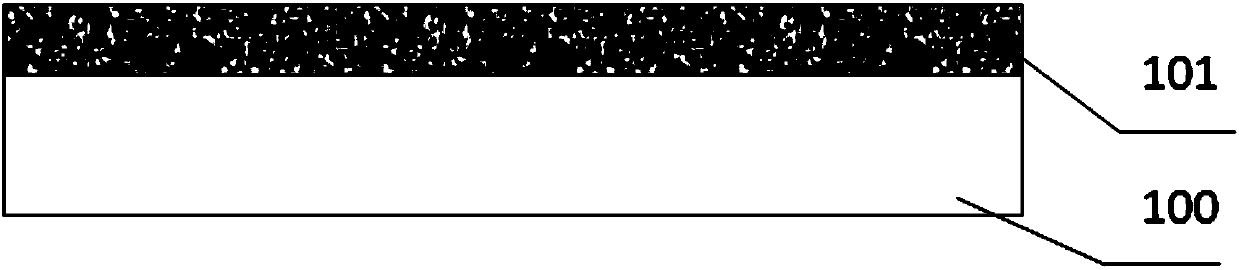

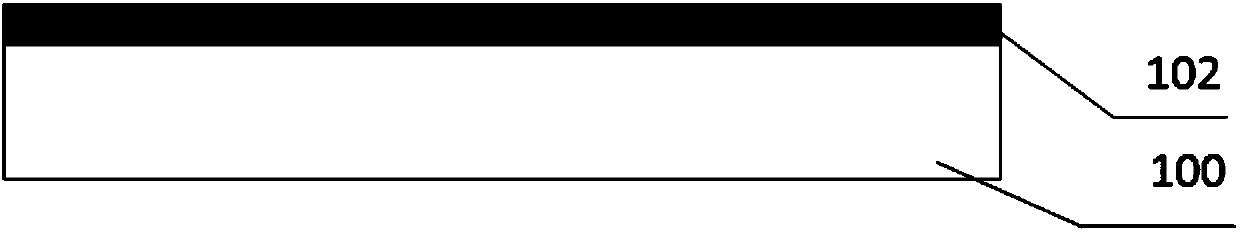

[0047] Such as figure 1 Shown is a schematic diagram of the preparation process of the conductive heating film, Figure 2-4 Shown is a schematic diagram of the product structure in the preparation process.

[0048] It should be noted that there are many graphene conductive pastes suitable for the present invention, and its main components include: film-forming resin, wetting and dispersing agent, graphene powder, and defoaming agent. Among them, the film-forming resin includes: polyacrylate, polyurethane, epoxy resin, polyolefin resin (such as EVA, PVB), etc.; wetting and dispersing agent and defoaming agent are commercially available common additives, such as BYK (BYK), Corresponding products of EFKA, TEGO and other companies.

Embodiment 1

[0050] S01. Graphene conductive paste consists of (the following parts are all parts by weight): polyacrylate emulsion (prepared by copolymerization of IBOMA and MMA monomers with a mass ratio of 5:1, Tg is 130 ° C, solid content 35wt% ) 25 parts, dispersant (DISPERBYK-190) 6 parts, graphene powder 7 parts, defoamer (BYK-019) 1 part. The above components were mixed evenly to form a graphene conductive paste, which was coated on the support substrate 100, dried at 85° C. for 5 minutes, heated and dried at about 150° C. for 10 minutes, and an initial conductive coating 101 was obtained.

[0051] S02. The supporting substrate 100 coated with the initial conductive coating 101 obtained in step S01 is placed in the cavity, and a glass plate with a smooth surface is placed horizontally on it (the side of the glass plate in contact with the coating is subjected to a release treatment, and the surface The tension is less than 20 dynes / cm). Close the chamber, start the vacuum pump to re...

Embodiment 2

[0056] S01. The composition of graphene conductive paste is (the following parts are all parts by weight): 10 parts of polyurethane emulsion (Netherlands Stahl PU653, Tg is 75 ° C), 5 parts of dispersant (DISPERBYK-190), graphene powder 6 parts, 1 part of defoamer (BYK-019). The above components were mixed evenly to form a graphene conductive paste, which was coated on the support substrate 100, dried at 90°C for 5 minutes, heated and dried at about 95°C for 10 minutes, and an initial conductive coating 101 was obtained.

[0057] S02. The supporting substrate 100 coated with the initial conductive coating 101 obtained in step S01 is placed in the cavity, and a glass plate with a smooth surface is placed horizontally on it (the side of the glass plate in contact with the coating is subjected to a release treatment, and the surface The tension is less than 20 dynes / cm). Close the chamber, start the vacuum pump to reduce the pressure in the chamber to 500Pa, turn on the heating,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com