Display panel module and display device

A display screen, staggered configuration technology, applied in the direction of identification devices, printed circuits, electrical equipment structural parts, etc., can solve problems such as increased power consumption, increased heating temperature, and reduced display quality, and achieves the effect of improving heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

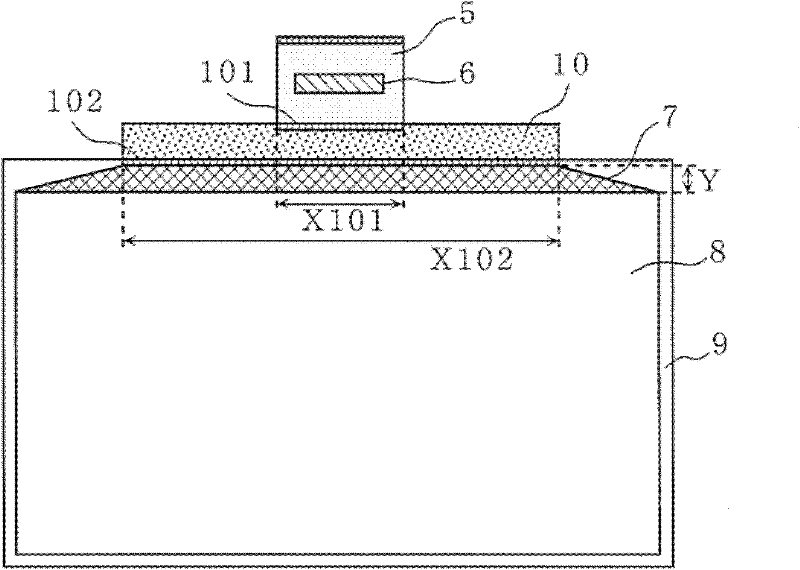

[0075] figure 1 is a plan view showing the structure of the display panel module in this embodiment.

[0076] The display module includes a film package 5 , a display 9 and a flexible printed board 10 . This display module has a structure in which the electrodes (terminals) of the film package 5 are connected to the display panel through the flexible printed board 10 while reducing the number of drive circuit elements 6 mounted on the film package 5 to one. 9 electrodes (terminals) are connected. Here, by making the width X102 of the connecting portion 102 between the flexible printed board 10 and the display screen 9 longer than the width X101 of the connecting portion 101 between the thin film package 5 and the flexible printed board 10, it is compatible with the thin film package 5 and the flexible printed board 10. Compared with the case where the display screen 9 is directly bonded, the length Y in the vertical direction of the wiring region 7 located on the display sc...

Deformed example 1

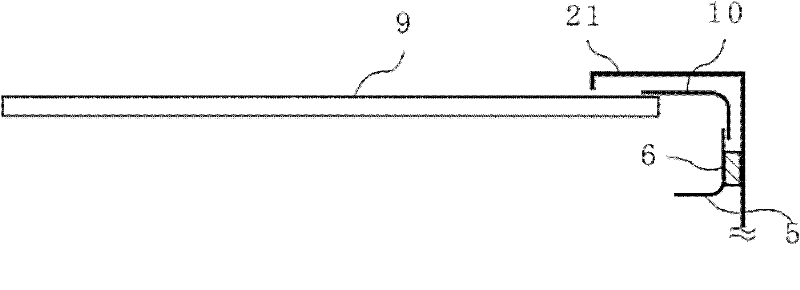

[0084] Second, use Figure 4 A modified example of the display module according to this embodiment will be described.

[0085] Such as Figure 4 It shows that in the display module of this modified example, by making the shape of the flexible printed board 10 trapezoidal, the area of the flexible printed board 10 can be suppressed to a necessary and minimum limit, and the number of parts required for the display module can be reduced. the cost of.

[0086] A plurality of electrodes 301 connected to the film package 5 are arranged on the upper bottom of the trapezoidal-shaped flexible printed board 10, and a plurality of electrodes 302 connected to the display screen 9 are arranged on the trapezoidal-shaped flexible printed board 10. The bottom of the plate 10. Also, the lower base of the trapezoidal shape is a side longer than the upper base.

Deformed example 2

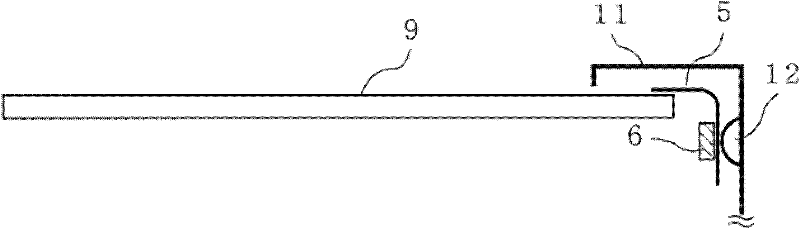

[0088] Second, use Figure 5 Another modified example of the display module according to the present embodiment will be described.

[0089] Such as Figure 5 As shown, the display module of this modified example has a structure in which a circuit element (hereinafter referred to as a control circuit element) 1 and a driving circuit element 6 are mounted on one thin film package 5, that is, a plurality of circuit elements are mounted on one thin film package 5. , a control circuit for controlling the drive circuit of the display screen 9 is mounted (mounted) on the circuit element (hereinafter, control circuit element) 1 . According to the structure of the present embodiment, in the display panel module, the number of drive circuit elements 6 can be reduced to one. As a result, by reducing the Figure 17 In the structure of the conventional display module shown, the cable 3, the source substrate 4, and the control substrate 2 used to connect the control circuit element 1 to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com