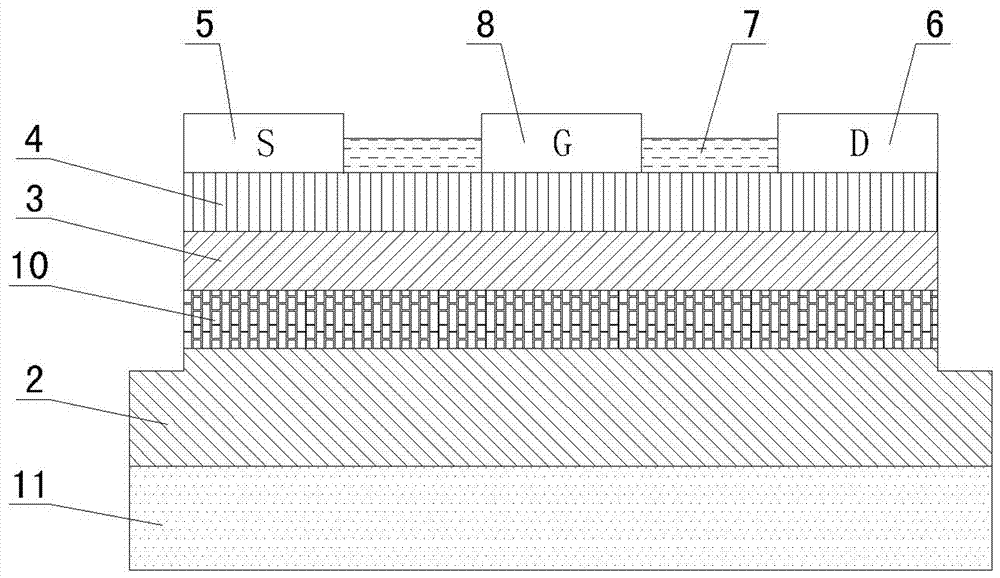

GaN power device based on ion implantation and manufacturing method thereof

A power device and ion implantation technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as implantation damage, quality degradation of material growth, and treatment pollution, so as to avoid damage, high repeatability, The effect of reducing electric leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

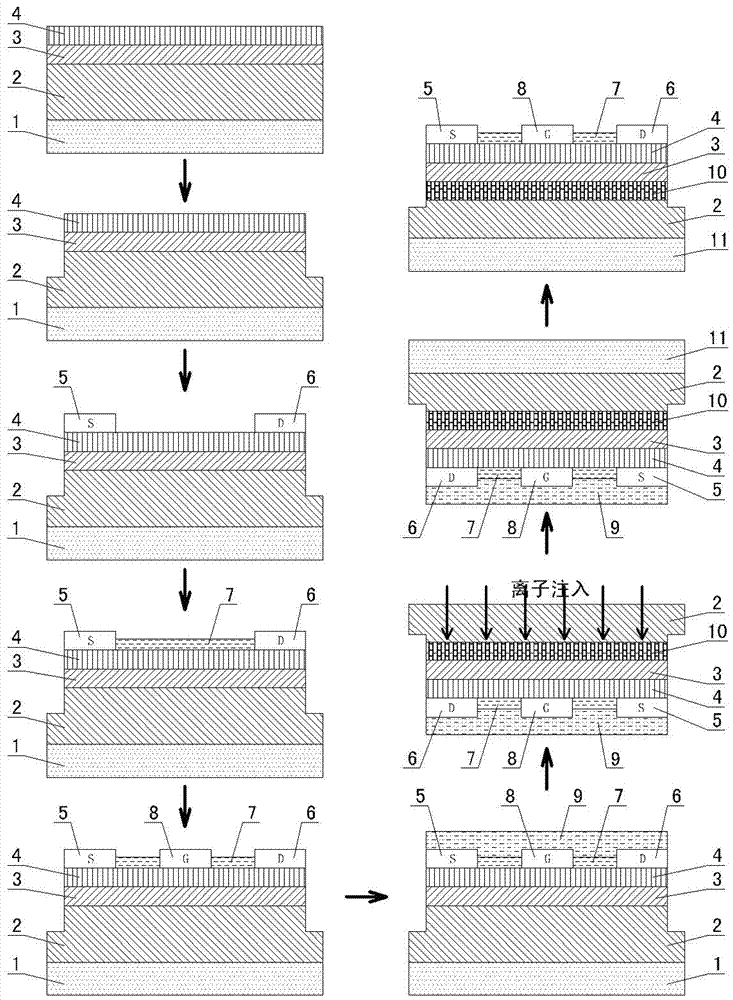

[0053] The embodiment of the present invention provides a method for manufacturing a GaN power device based on ion implantation, which includes the following steps:

[0054] Step 1), using metal organic chemical vapor deposition equipment to sequentially grow GaN buffer layer, GaN channel layer and AlGaN barrier layer on the silicon substrate, the epitaxial growth temperature is between 950°C and 1350°C;

[0055] Step 2) Clean the surface of the AlGaN / GaN sample grown on the silicon substrate. The specific method is: ultrasonic cleaning in acetone and isopropanol solutions for 5 minutes, and then soaking in the mixed solution of sulfuric acid and hydrogen peroxide and pure hydrochloric acid. 10 minutes, and after rinsing in deionized water, blow dry with nitrogen, and use a hot plate to dry the residual moisture on the surface;

[0056] Step 3) Prepare a photoresist mask on the AlGaN barrier layer using a conventional UV lithography process as a pattern for mesa etching in the...

Embodiment 2

[0065] This embodiment differs from Embodiment 1 in that:

[0066] In step 1), a GaN buffer layer, a GaN channel layer and an AlGaN barrier layer are sequentially grown on the SiC substrate;

[0067] Step 5) is to use LPCVD equipment to make SiN x As a passivation layer for GaN power devices, the deposition temperature is 780°C, SiN x The thickness is 300nm;

[0068] In step 8), the silicon carbide substrate is removed by grinding combined with ICP etching.

Embodiment 3

[0070]This embodiment differs from Embodiment 1 in that:

[0071] In step 1), a GaN buffer layer, a GaN channel layer and an AlGaN barrier layer are sequentially grown on the sapphire substrate;

[0072] Step 5) is to use atomic layer deposition equipment (ALD) to make Al 2 o 3 As the passivation layer of the device, the deposition source uses Al-CH 3 And Al-OH, the deposition thickness is 50nm;

[0073] In step 8), the sapphire substrate is removed by laser lift-off; moreover, the ion implantation uses Al ions for implantation isolation and is performed twice, the first implantation is performed with an energy of 135 KeV, and the implantation dose is 5 ×10 14 cm 2 , the second implantation was performed using an energy of 90 KeV with an implantation dose of 3 × 10 14 cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com