Method for producing light-emitting device and light emitting device

A technology for a light-emitting device and a manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, and electric-solid-state devices, etc., can solve the problems of poor operation efficiency, the quality of the light-emitting device 300 is kept constant, and the removal of the substrate 302 is difficult. Effects of improved heat dissipation characteristics and simple quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

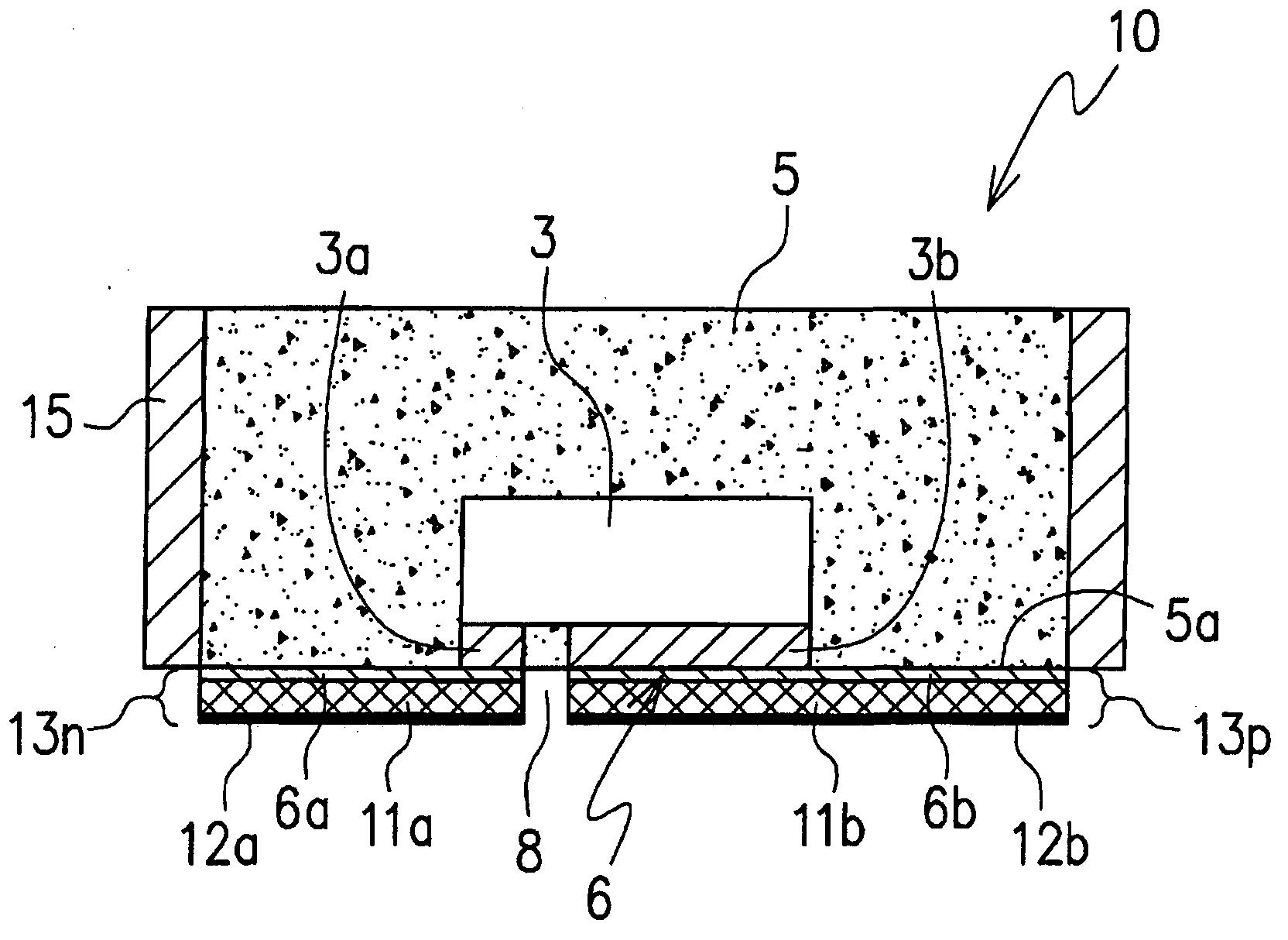

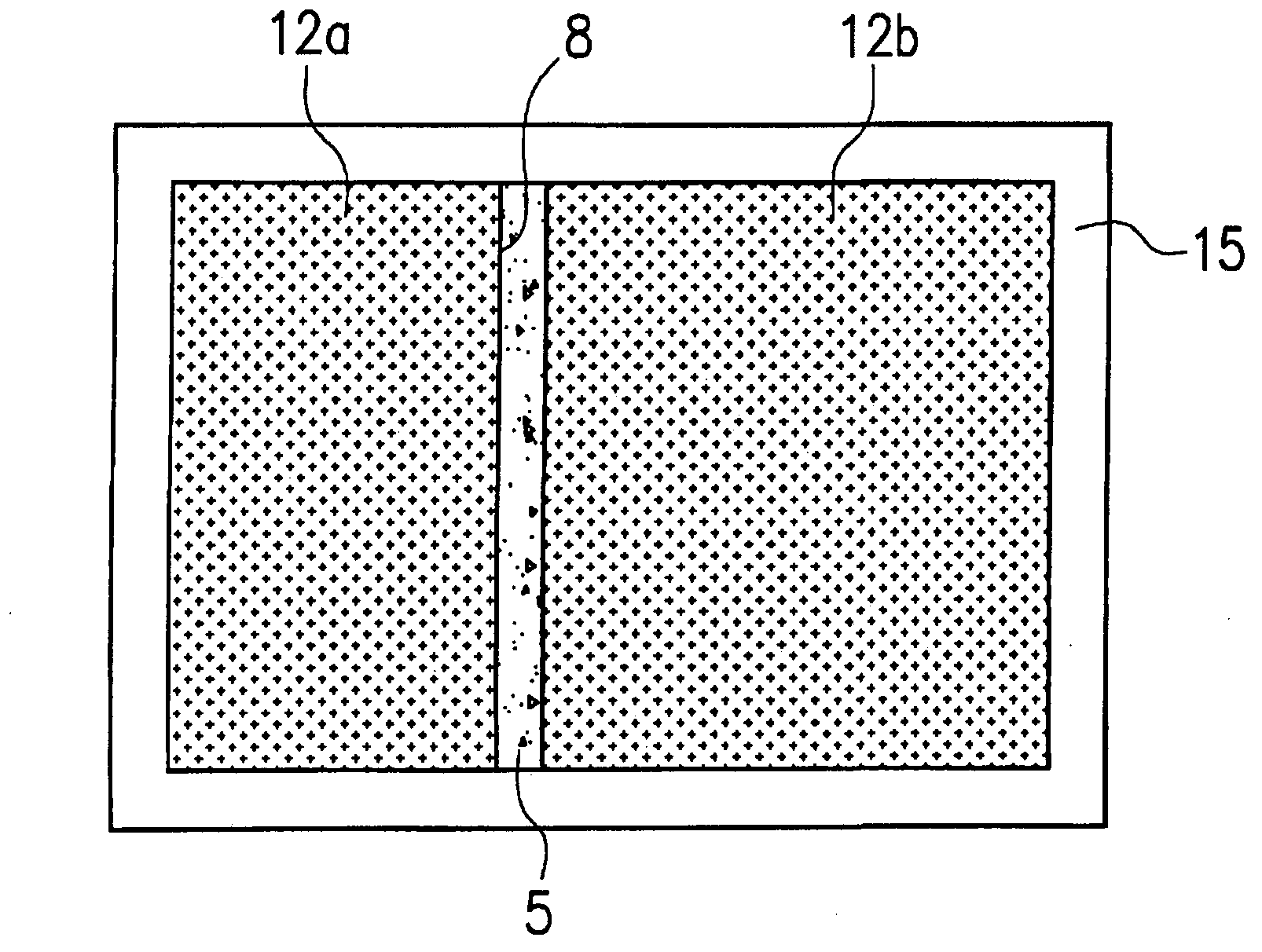

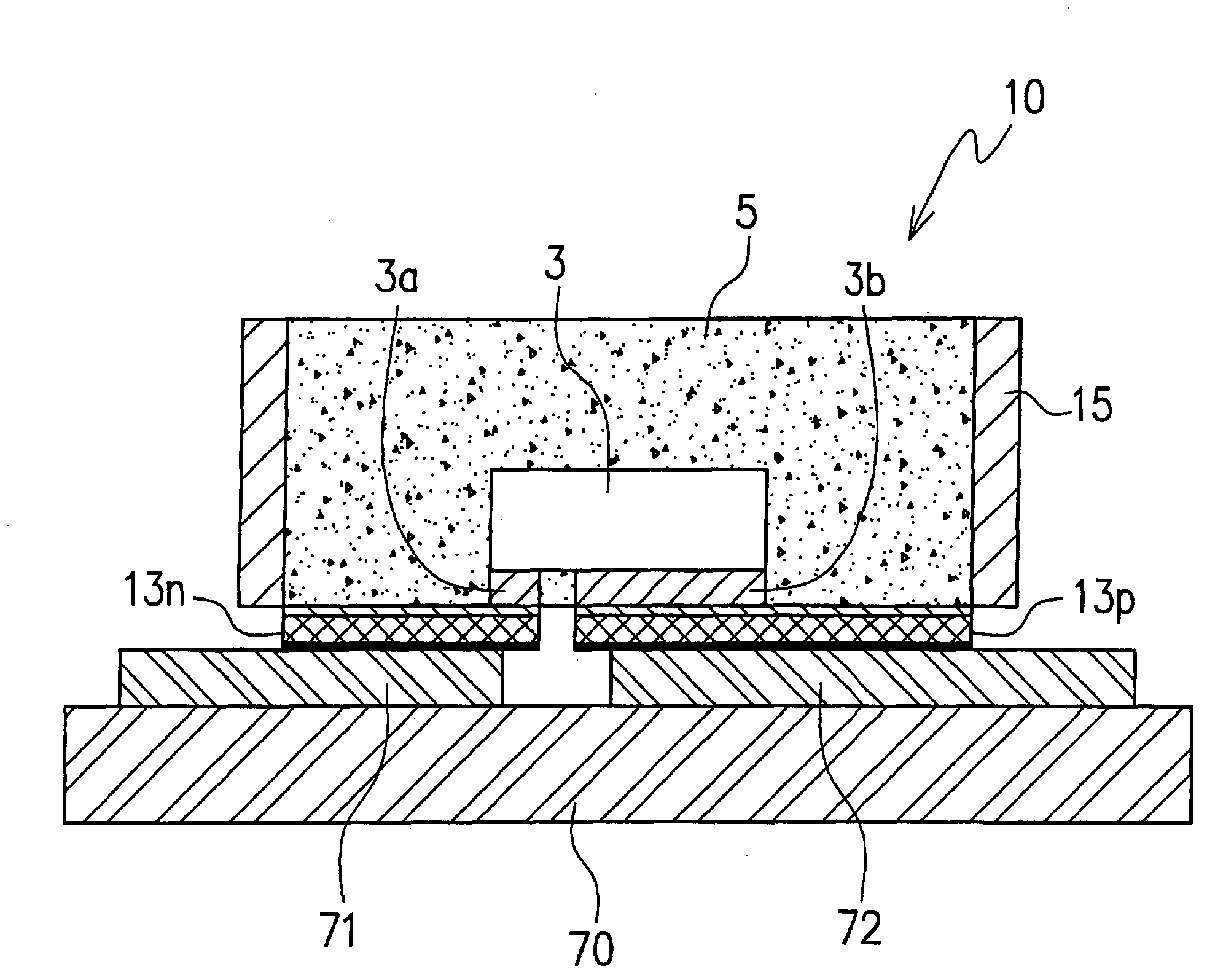

[0071] Figure 1 to Figure 3 A light-emitting device manufactured by the manufacturing method of the first embodiment of the present invention is shown, Figure 4 to Figure 25 The steps of the manufacturing method of the first embodiment are shown.

[0072] exist figure 1 as well as figure 2Among them, the light-emitting device 10 has: a light-emitting diode element (hereinafter, a light-emitting element) 3 having an N electrode 3a and a P electrode 3b as a pair of element electrodes; a transparent sealing resin or a light-transmitting sealing resin 5 mixed with fluorescent particles (hereinafter the sealing member) seals the light emitting element 3 in a state where each of the pair of element electrodes of the light emitting element 3 exposes the lower surface as at least one side; and a pair of external connection electrodes are formed on the sealing member 5 At least one surface of the exposed pair of element electrodes is electrically connected to an N electrode 3 a ...

no. 2 Embodiment approach )

[0091] Figure 26 A light-emitting device manufactured by the manufacturing method of the second embodiment of the present invention is shown, Figure 27 to Figure 32 The steps of the manufacturing method of the second embodiment are shown.

[0092] The basic structure of the light emitting device 20 of this embodiment and figure 1 The light-emitting device 10 according to the first embodiment shown is the same, so the same symbols are attached to the same structures, and detailed descriptions are omitted.

[0093] This light-emitting device 20 differs from the previous light-emitting device 10 in that a protective film 25 is formed on substantially the entire surface of the lower surface 5 a of the sealing member 5 that resin-seals the light-emitting element 3 . The protective film 25 is formed for the purpose of reinforcing the flexible sealing member 5 made of silicone resin, and the N external connection electrode 23n formed on the lower surface of the sealing member 5 ...

no. 3 Embodiment approach )

[0108] Figure 33 A light-emitting device obtained by the manufacturing method of the third embodiment of the present invention is shown, Figure 34 The characteristic steps of the manufacturing method of the third embodiment are shown. In addition, the same reference numerals are assigned to components equivalent to those in the first embodiment, and detailed description thereof will be omitted.

[0109] Such as Figure 33 As shown, the light-emitting device 30 of this embodiment includes: a light-emitting element 3 having an upper surface, a lower surface, and a peripheral surface between the upper surface and the lower surface, and a pair of element electrodes on the lower surface; a sealing member, so that the light-emitting element 3 is arranged in such a way that a pair of element electrodes of the light emitting element 3 are exposed to seal the light emitting element 3; and a pair of external connection electrodes are electrically connected to the pair of element ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com