Circuit board and electronic device provided with same

一种电路基板、贯通孔的技术,应用在电路热装置、电路、印刷电路等方向,能够解决散热特性降低、接合面积小、接合不良等问题,达到减小凹陷、提高散热特性、提高接合强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

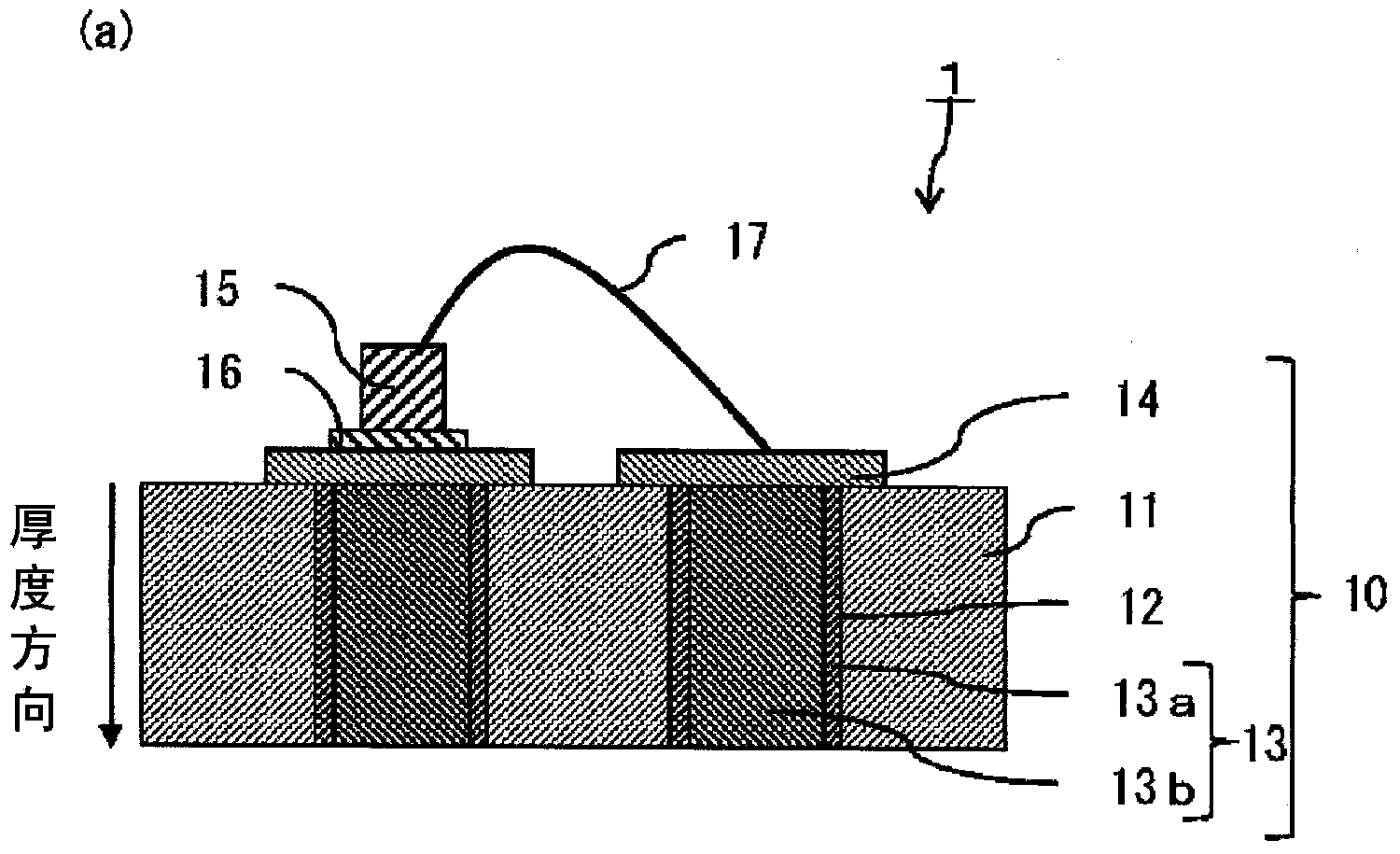

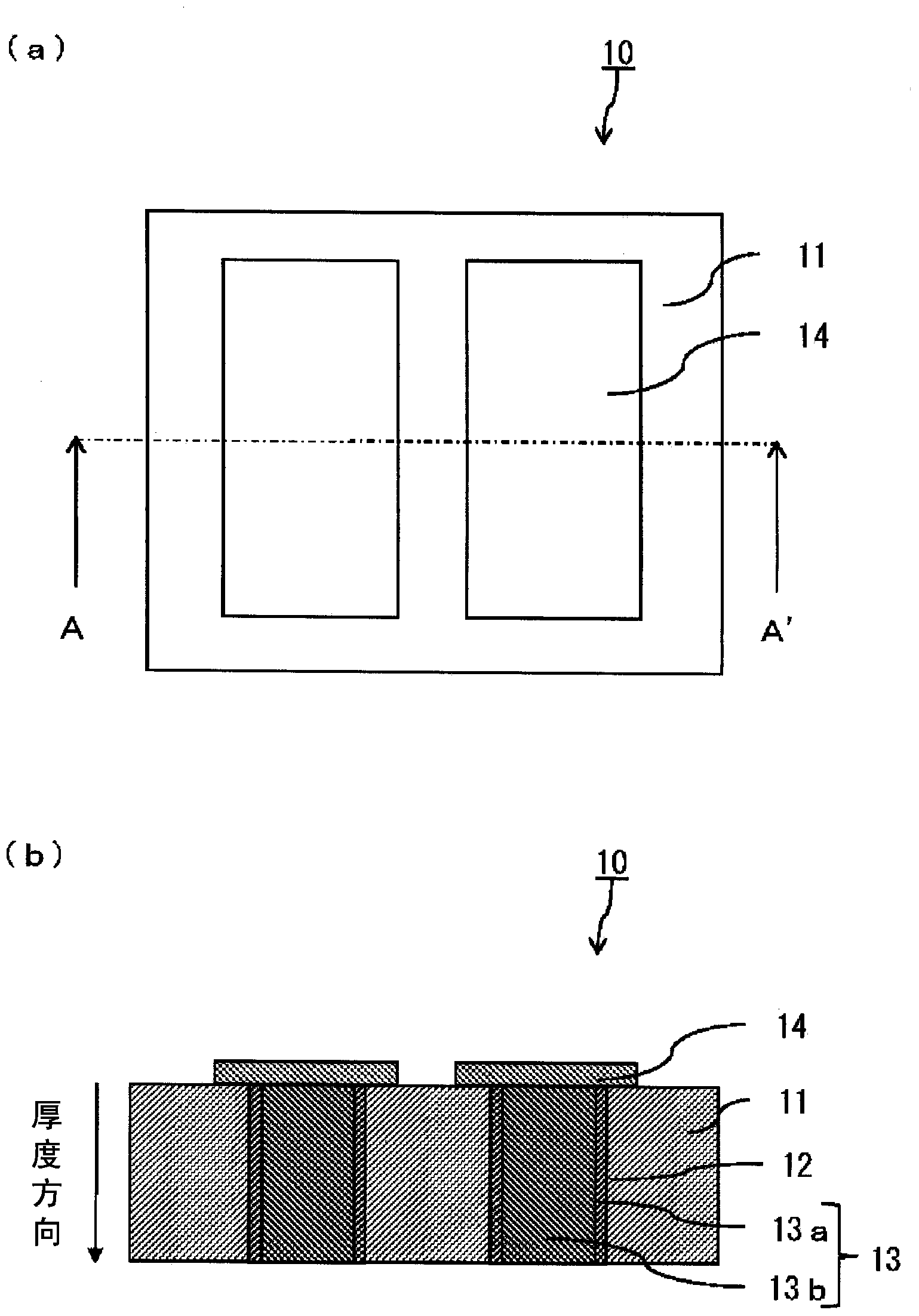

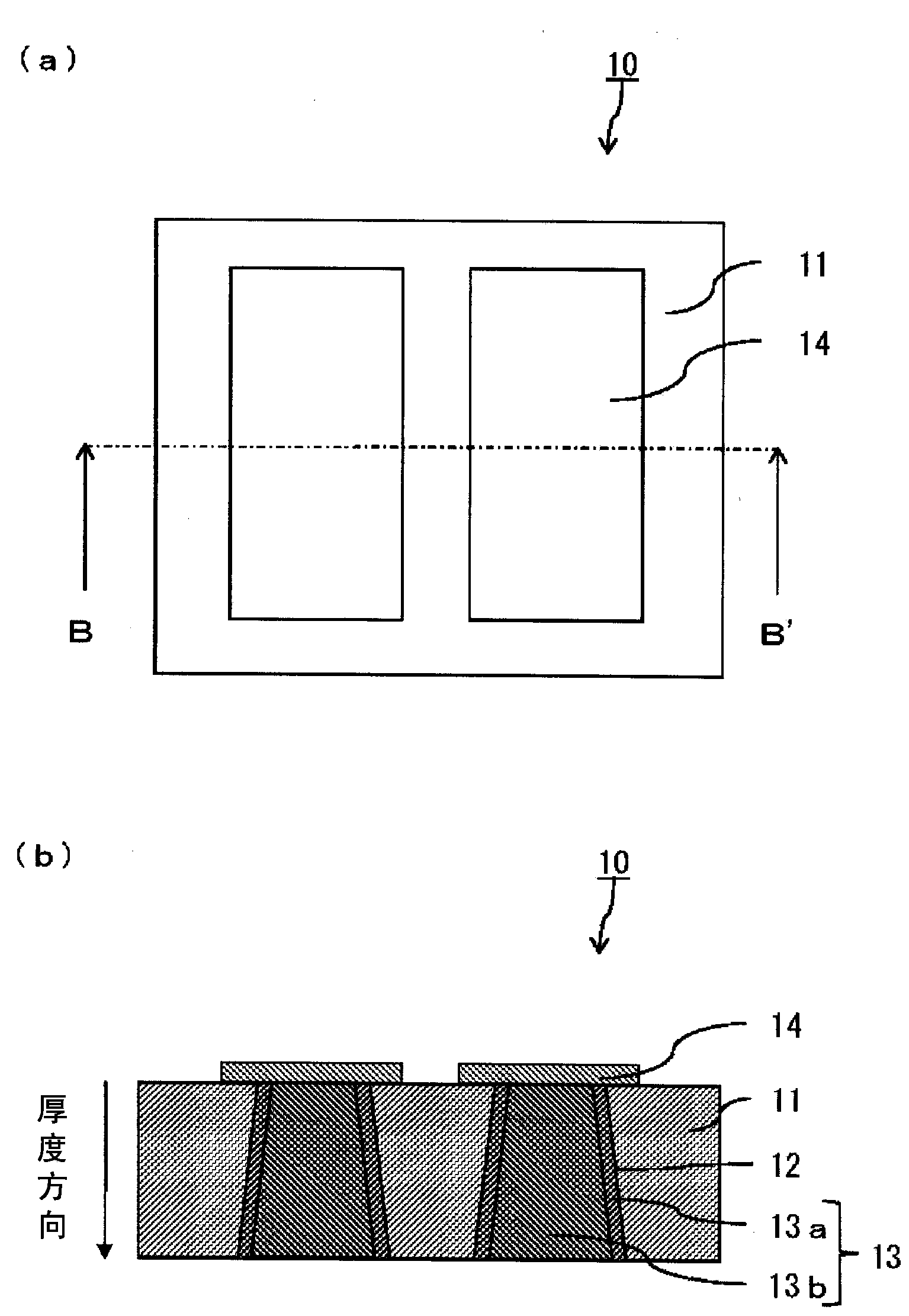

[0067] Samples were produced in which the average crystal grain diameters of the first region 13 a and the second region 13 b were different, and tests were performed on the dishing, heat dissipation characteristics, and reliability of the via conductor 13 .

[0068] First, using silica and magnesia as sintering aids, an alumina-based sintered body having an alumina content of 96% by mass was produced. It should be noted that groove processing is performed on the ceramic sintered body 11 so that a plurality of samples can be obtained.

[0069] Then, laser processing was performed on the ceramic sintered body 11 to form a through-hole 12 having a diameter of 130 μm from one end to the other end. Next, for the metal pastes used to prepare the samples, those made of copper and having an average particle size of 0.5 μm, 2 μm, and 6 μm in the mixing ratio of metal powders were used to obtain the average crystal grain size shown in Table 2. The way to adjust the metal mixed powder ...

Embodiment 2

[0082] Next, samples were produced in which the second region 13b of the penetrating conductor 13 and the average crystal grain size of the metal wiring layer 14 were different, and tests regarding heat dissipation characteristics and reliability were performed. As a manufacturing method, in order to make the average crystal grain size of the metal wiring layer 14 different on the penetrating conductor 13 having the same structure as sample No. 14 of Example 1, Sample Nos. 4, 8, and 14 to form the metal wiring layer 14 using the metal paste used in the formation of the second region 13b. It should be noted that the structure of the metal wiring layer 14 is the same as the second region 13b of the sample No. 4 of Example 1 is the sample No. 19, and the same as the sample No. 14 is the sample No. 20. The same as sample No.8 is sample No.21. Except changing the metal paste used, it carried out by the same method as Example 1.

[0083] Furthermore, a heat dissipation characteris...

Embodiment 3

[0088] Next, samples were produced in which the glass content in the first region 13a was different from the glass content in the second region 13b, and tests regarding heat dissipation characteristics and reliability were performed. As a manufacturing method, the mixing ratio of the second metal paste was changed, the glass powder of sample No. 22 was changed to 2.0% by mass, the glass powder of sample No. 23 was changed to 3.0% by mass, and the The glass powder was changed to 4.0% by mass. In addition, the ratio of terpineol to acrylic resin was fixed at 3.4, and the addition amount of the organic vehicle was increased / decreased according to the amount of glass powder. The same method as in Example 1 and Example 2 was carried out except that the second metal paste used was changed.

[0089] The heat dissipation characteristic test and the heating cycle test were performed by the same method as in Example 1. In the method of measuring the glass content in the first region 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com