Electronic component package and method for producing same

A technology for electronic components and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, etc., can solve problems such as insufficient connection reliability of heat dissipation characteristics, and achieve the effect of improving connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] The electronic component package of the present invention was produced as follows.

[0113] Materials used in the production of the electronic component package of the present invention are as follows.

[0114] 1. Adhesive carrier (adhesive film): Adhesive single-sided tape (adhesive layer about 15 μm + polyester film about 200 μm) about 200mm×about 200mm

[0115] 2. Sealing resin layer: liquid epoxy resin

[0116] 3. Metal foil: single-sided glossy copper foil (about 18μm) / roughened surface on the resin side

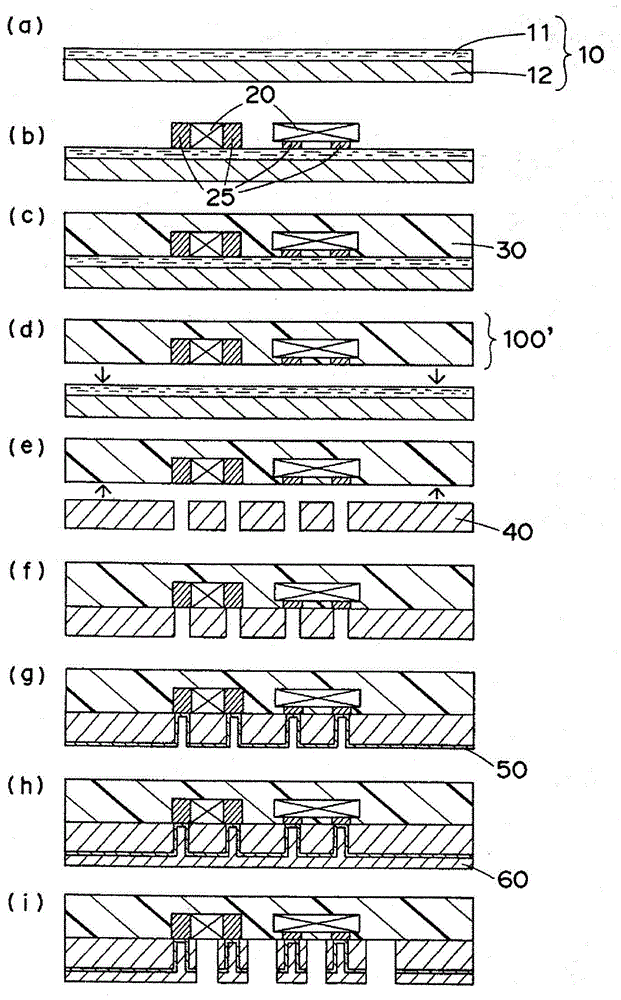

[0117] An electronic component package was manufactured according to the following steps.

[0118]

[0119]

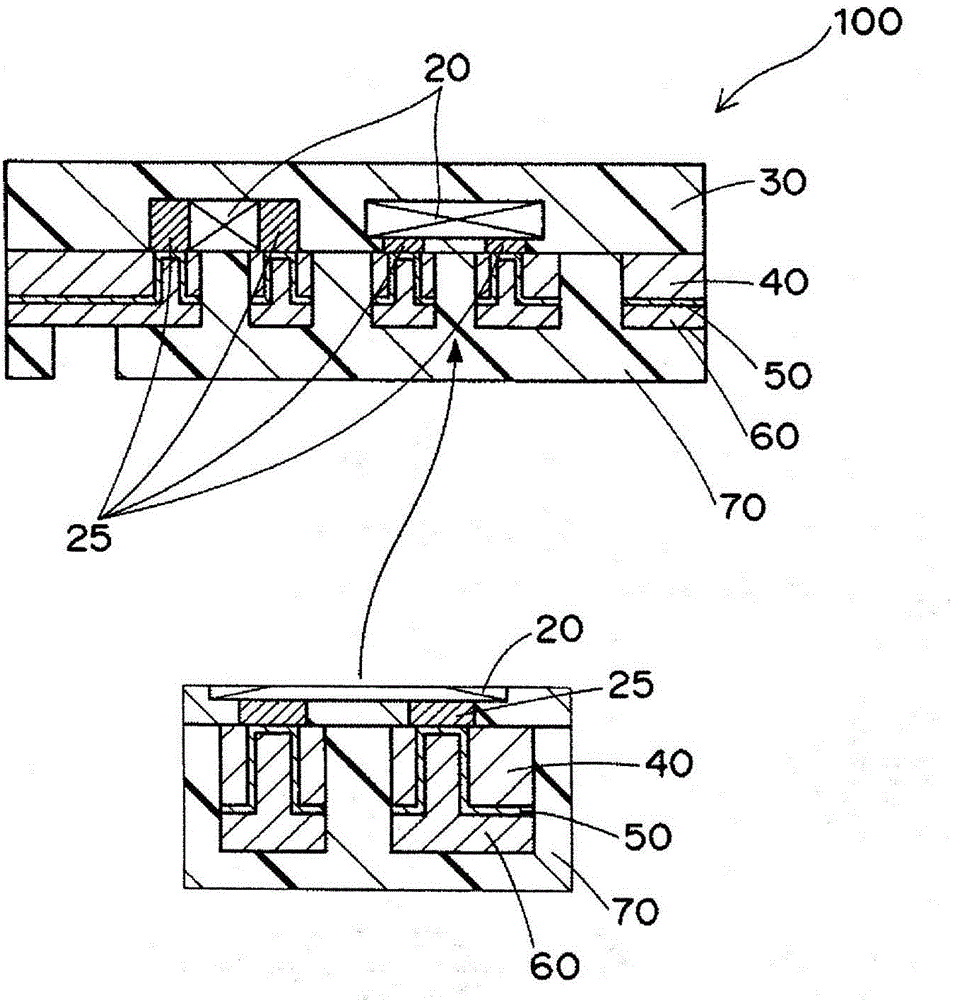

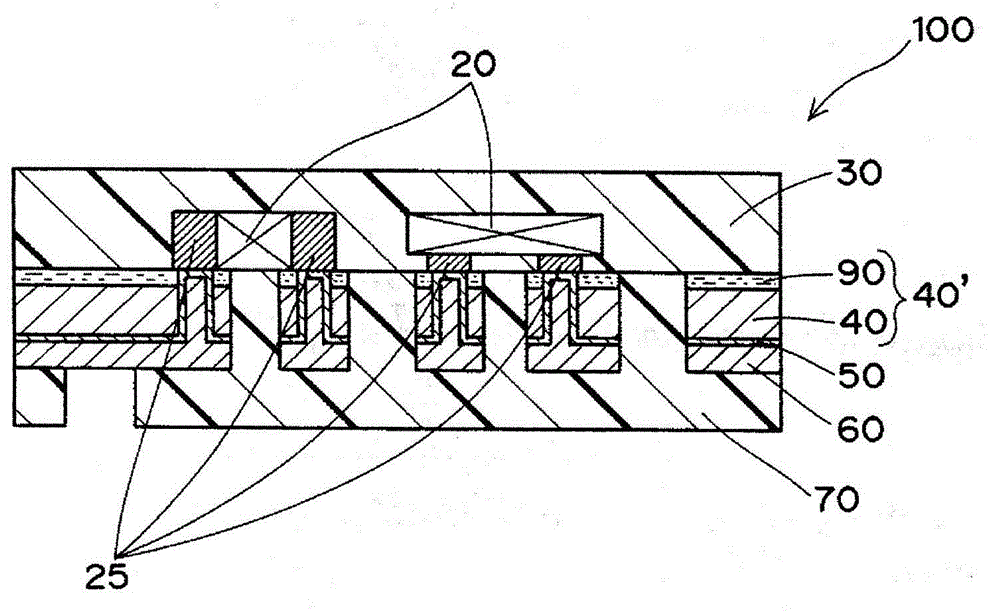

[0120] Since the metal foil 40 constituting the metal wiring layer is in direct contact with the sealing resin layer 30 through the above steps, and the metal plating layer constituting the metal wiring layer is in direct contact with the electrode 25 of the electronic component 20, the heat from the electronic component can be suppressed. The he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com