Semiconductor device and method for mfg. same

A semiconductor and device technology, applied in the field of manufacturing such semiconductor devices, can solve the problems of reducing mechanical reliability of packaging and defects in connection parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

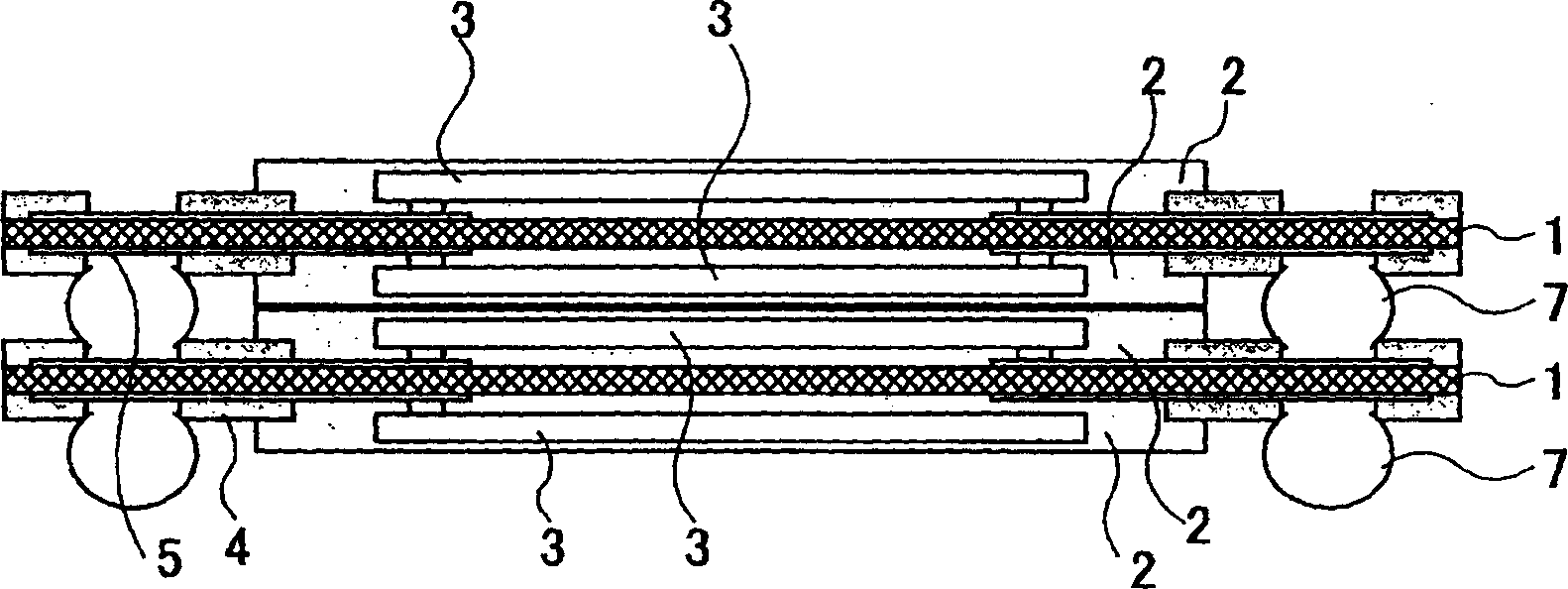

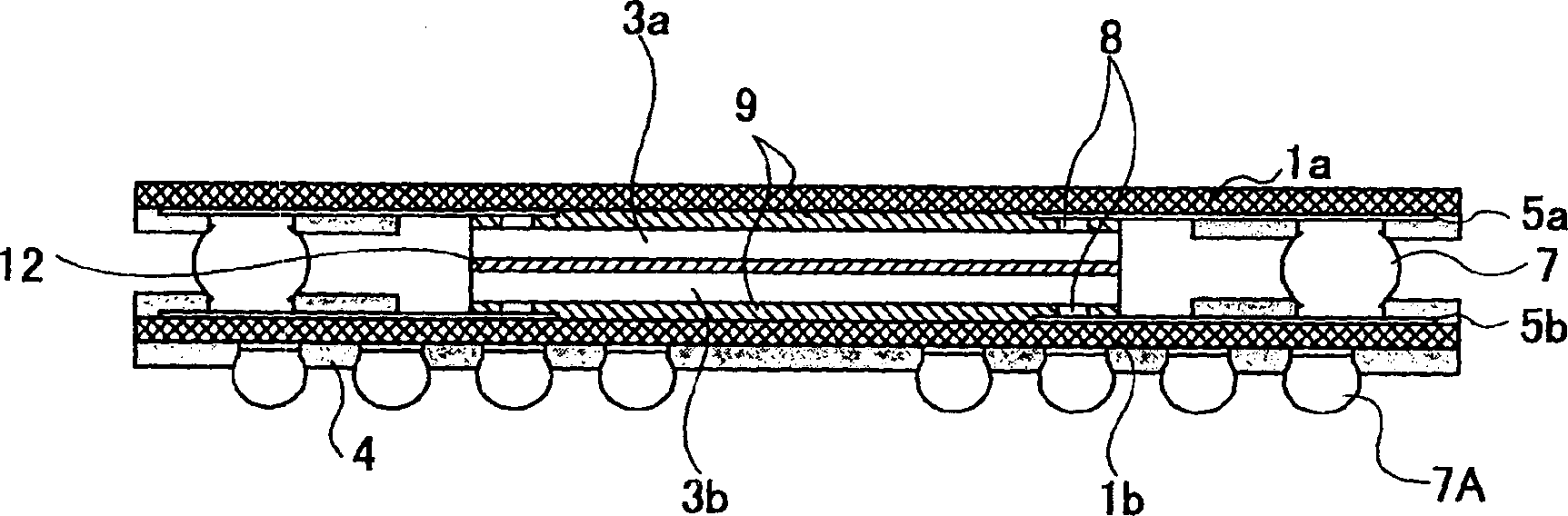

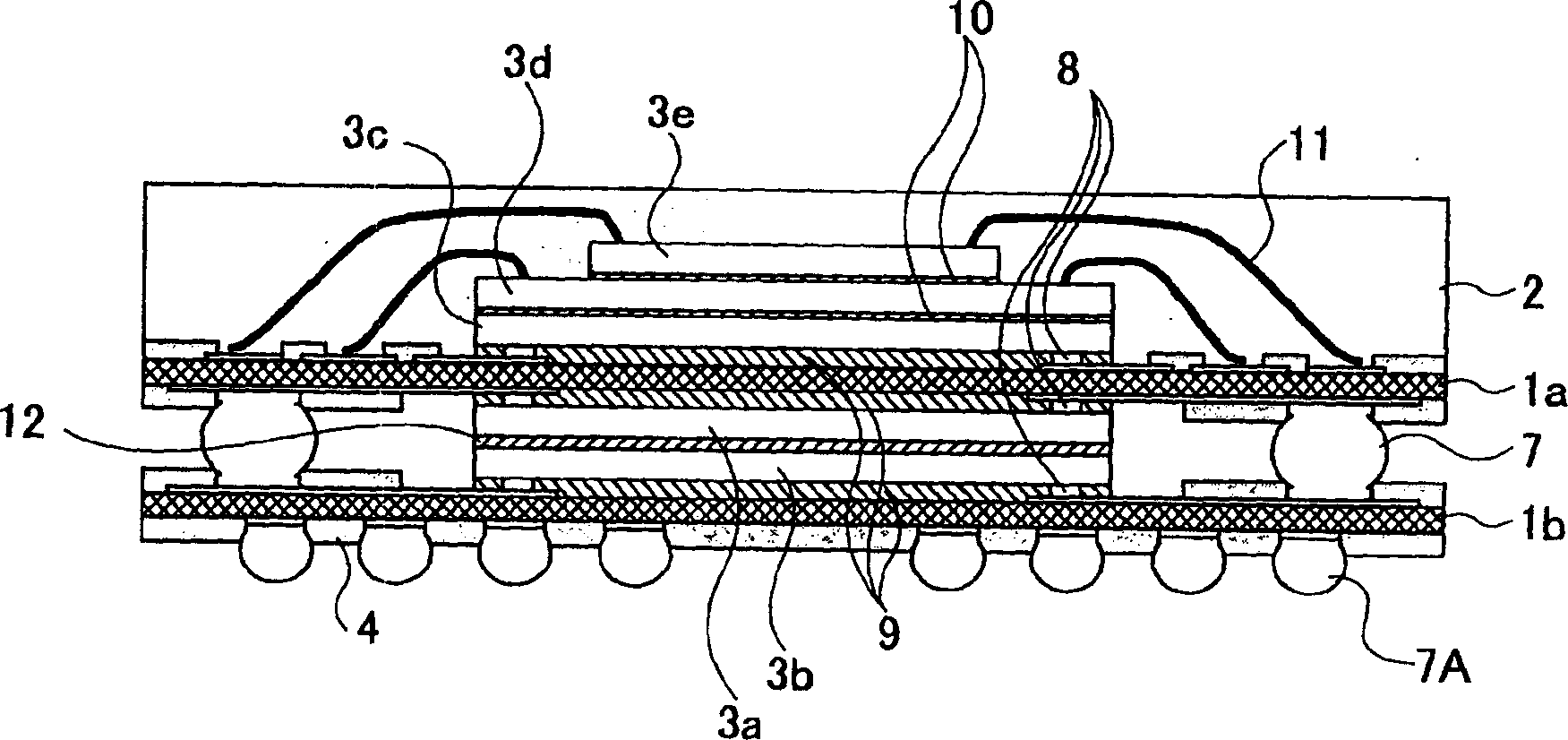

[0039] will now refer to figure 2 A semiconductor device according to a first embodiment of the present invention is described. figure 2 is a cross-sectional view of the semiconductor device according to the first embodiment of the present invention.

[0040] figure 2 The semiconductor device shown in has a structure in which an interposer 1a mounted with a semiconductor chip 3a and an interposer 1b mounted with a semiconductor chip 3b are superimposed. The interposer 1a and the interposer 1b are rearranged substrates, and are formed of polyimide tape substrates, glass epoxy resin substrates, organic substrates (polycarbonate), or the like. The interposer 1a and the interposer 1b are connected to each other by solder balls 7 as conductive members.

[0041] The semiconductor chip 3a is mounted on the interposer 1a by a flip-chip mounting method generally called face-down mounting. That is, the semiconductor chip 3 a is electrically connected to electrode blocks formed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com