Portable electronic device and method for manufacturing housing of the electronic device

A technology for portable electronic equipment and casings, which is applied in the directions of electrical equipment casings/cabinets/drawers, electrical components, chassis/boxes/drawer parts, etc. , can not be attached, etc., to achieve the effect of improving heat dissipation characteristics and/or heat diffusion characteristics, excellent heat dissipation characteristics, and reliable heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the present invention will be described in detail based on drawings showing embodiments.

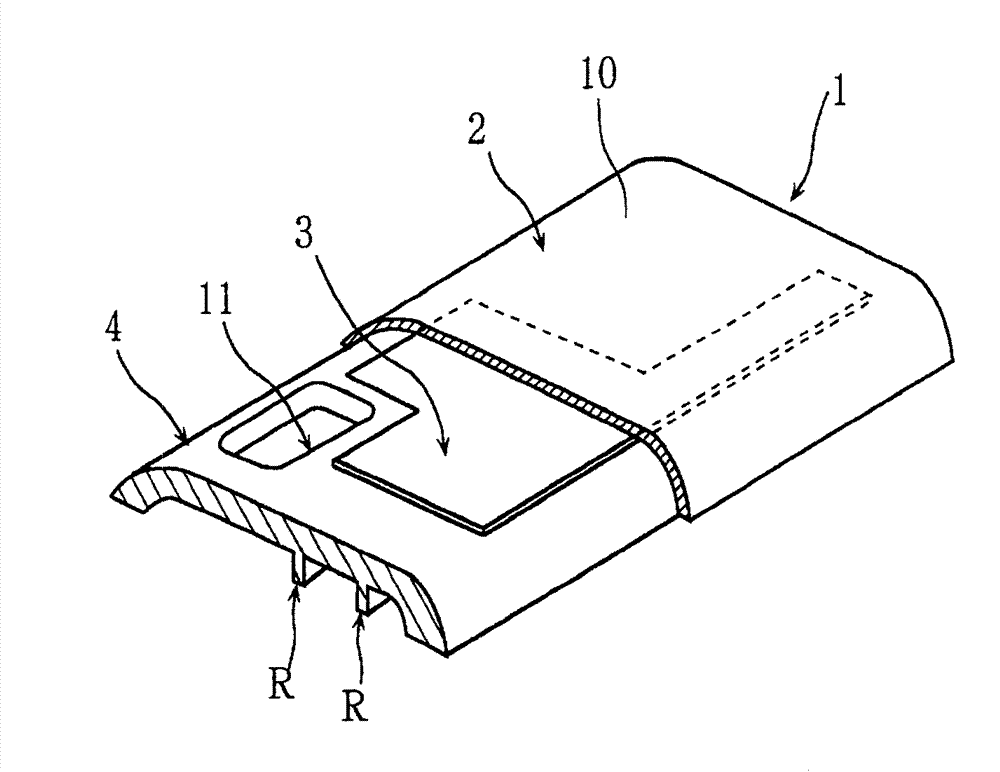

[0043] like figure 1 and figure 2 As shown, the portable electronic device of the present invention is a mobile phone or a smart phone, a tablet type communication terminal, a PDA, an electronic dictionary, and a notebook computer, etc., and utilizes a housing member 1 to encapsulate an internal electronic component 5, and the internal electronic component 5 includes components that generate heat along with use. The heating part6.

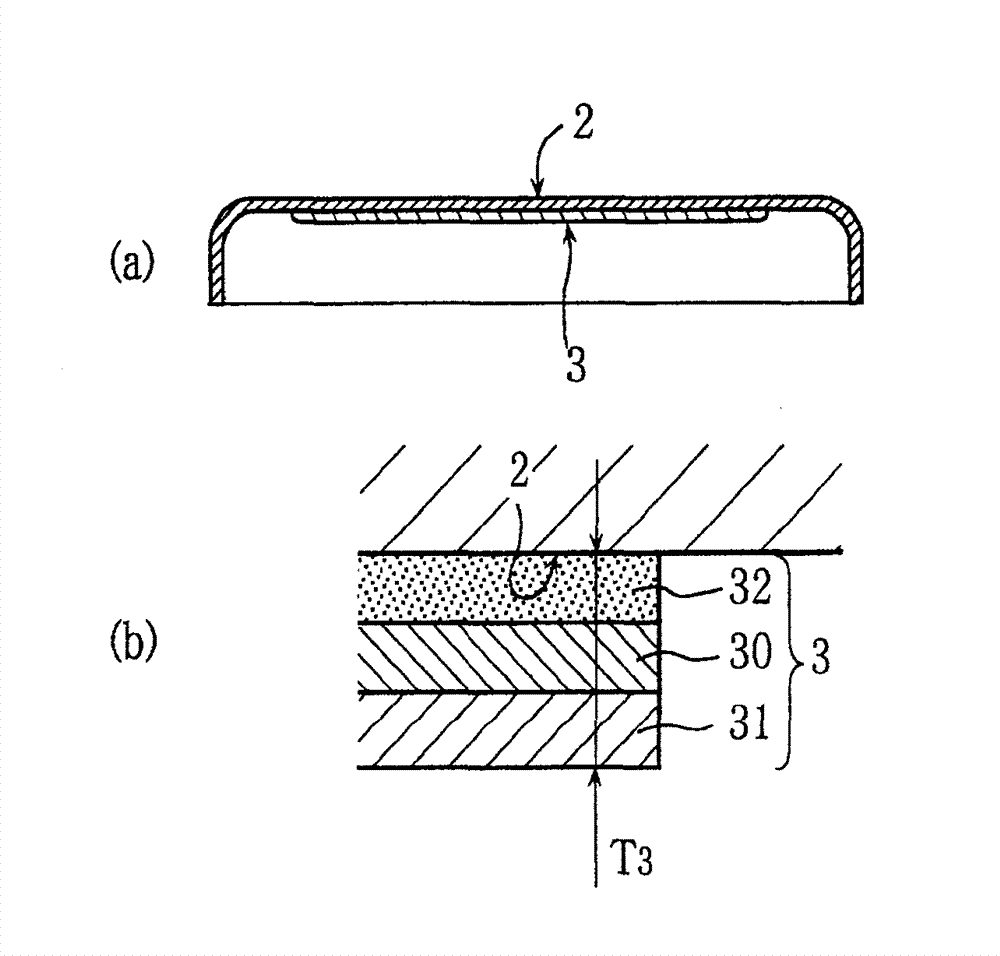

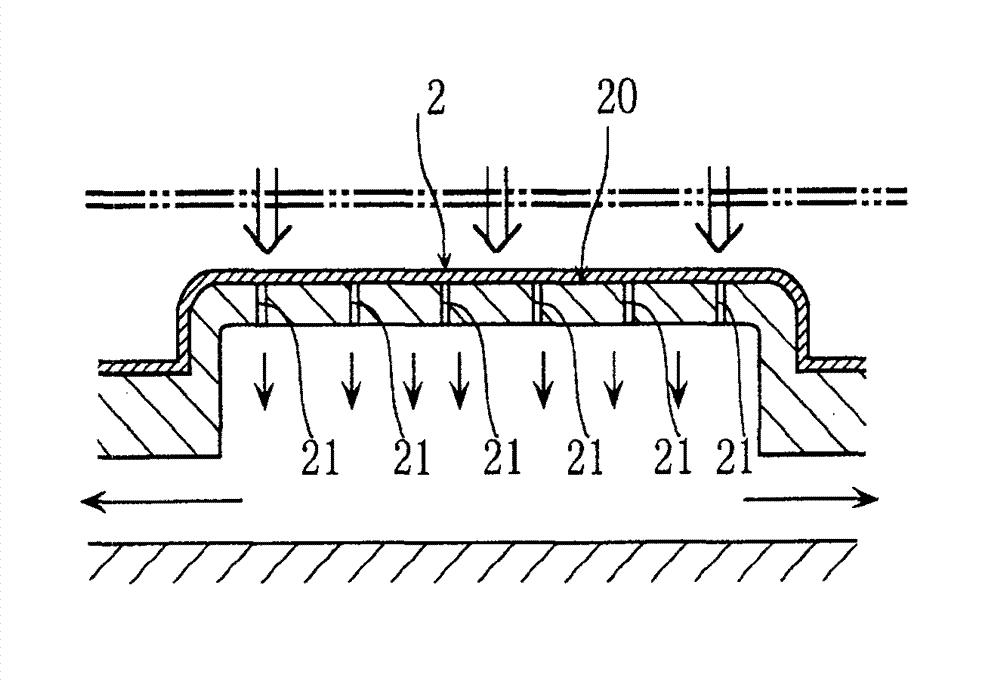

[0044] The portable electronic device of the present invention has a case member 1 comprising: a thin-walled outer wall portion 2 forming a case outer surface 10; a heat-conductive sheet body 3 laminated on a part of the back surface of the thin-walled outer wall portion 2, and , conduct heat from the heat generating part 6 of the internal electronic component 5, and dissipate heat from the outer surface 10 of the housing; Cured, lamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com