Light-emitting diode and preparation method thereof, and solar cell and preparation method thereof

A technology of light emitting diodes and electrode layers, which is applied in the fields of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of complex electrode preparation process of LED devices, and achieve the effect of improving compound efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the light-emitting diode provided by the present invention and its preparation method will be described in detail below in conjunction with the accompanying drawings.

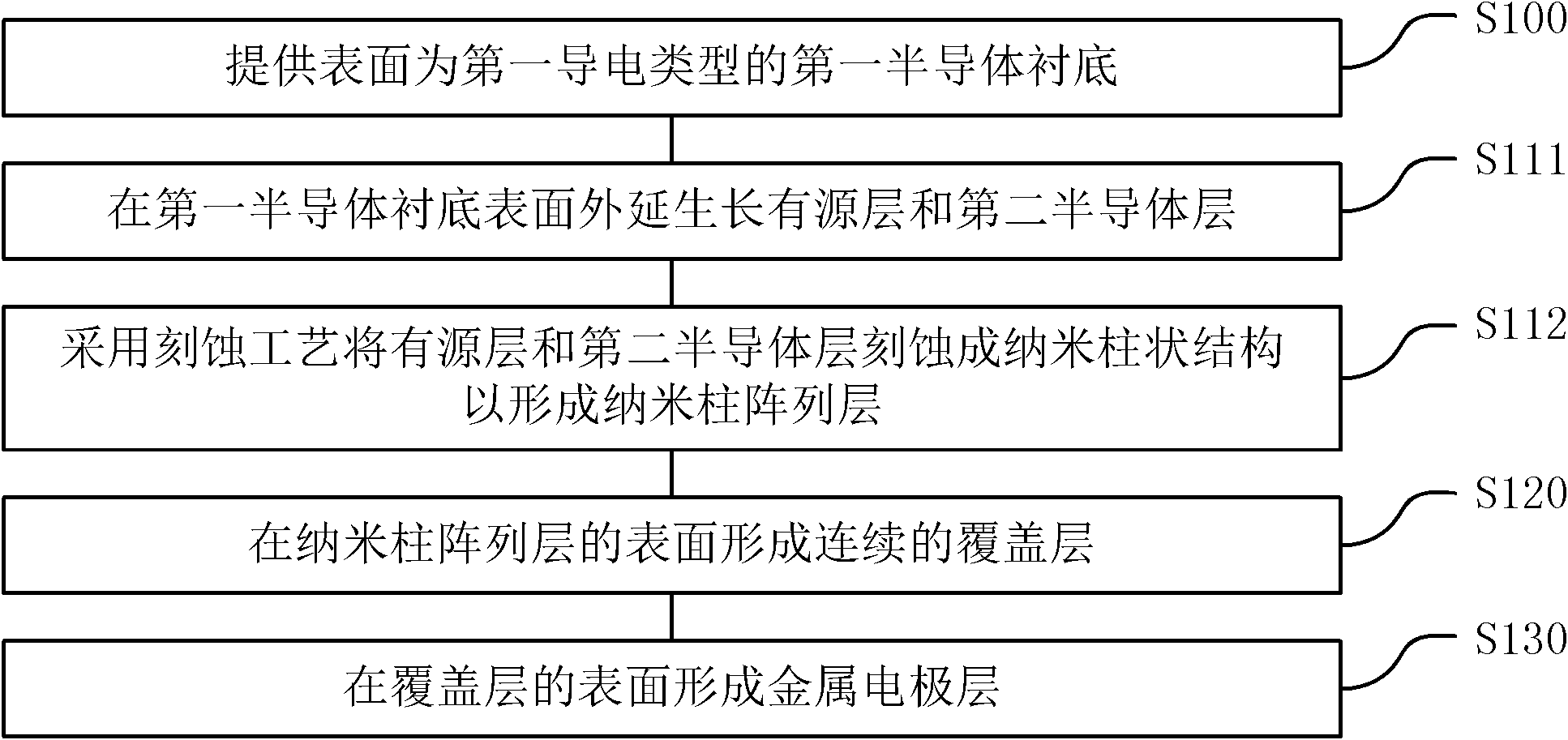

[0021] attached figure 1 Shown is a schematic diagram of the implementation steps of a specific embodiment of the present invention, including: Step S100, providing a first semiconductor substrate with a surface of the first conductivity type; Step S111, epitaxially growing an active layer and a second semiconductor substrate on the surface of the first semiconductor substrate. Semiconductor layer; step S112, using an etching process to etch the active layer and the second semiconductor layer into a nano-pillar structure to form a nano-pillar array layer; step S120, forming a continuous covering layer on the surface of the nano-pillar array layer; step S130, forming a metal electrode layer on the surface of the covering layer.

[0022] attached Figure 2A to attach Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com