Light-emitting diode with composite polar face electron blocking layer

An electron blocking layer, light-emitting diode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of large lattice mismatch, uneven distribution of carriers, low carrier recombination efficiency and low luminous efficiency, etc. Achieve the effect of increasing the probability and reducing the leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

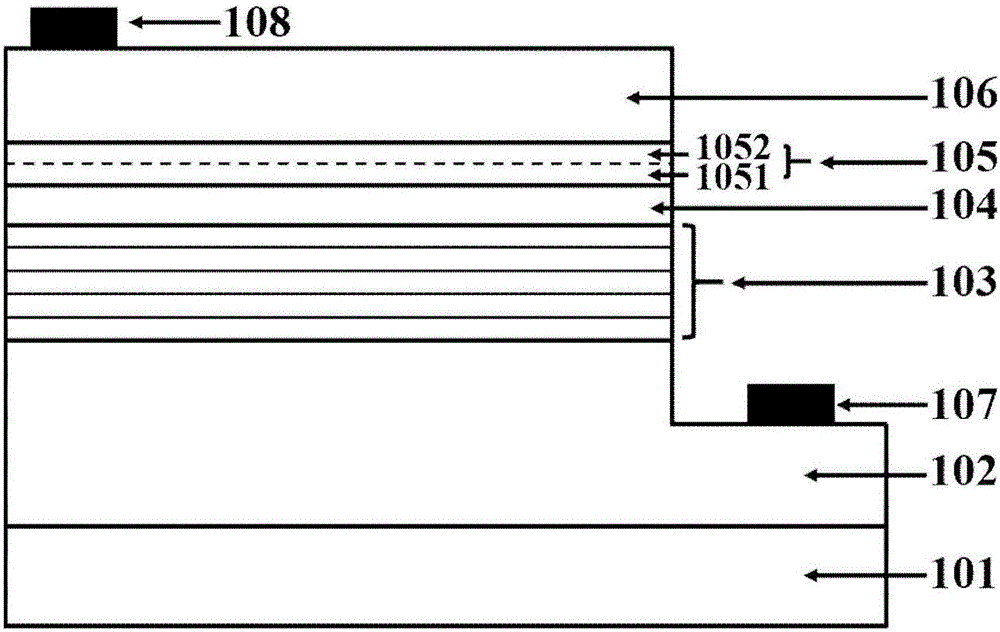

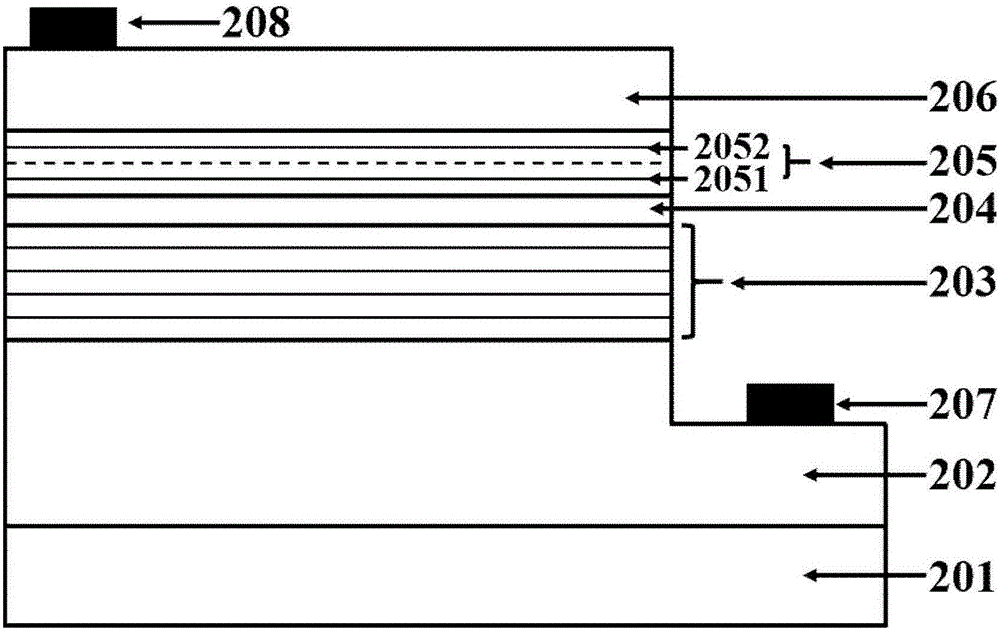

[0034] Such as figure 2 Shown is an LED with a composite polar surface electron blocking layer, including a sapphire substrate 201, a metal polar surface n-type GaN layer 202, a metal polar surface InGaN / GaN multi-quantum well layer 203, Metal polar plane p-type AlGaN layer 204, metal polar plane p-type electron blocking layer 2051 of GaN / AlGaN superlattice structure and nitrogen polar plane p-type electron blocking layer 2052 of GaN / AlGaN superlattice structure The composite polar plane p-type electron blocking layer 205, the nitrogen polar plane p-type GaN layer 206, the n-electrode 207 provided on the metal polar plane n-type GaN layer, and the nitrogen polar plane p-type GaN layer The p-electrode 208 .

[0035] The n-type GaN layer 202 on the metal polar surface is used as the n-type region of the LED, and its thickness is between 0.5 and 2 μm. This layer is doped with Si element, and the free electron concentration in it is 1×10 18 ~1×10 21 cm -3 between.

[0036] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com