Double-layer airflow quartz fairing reaction chamber apparatus for MOCVD system

A fairing and reaction chamber technology, applied in the field of III-V compound semiconductor material epitaxial growth equipment, can solve the problems that the reaction chamber device cannot take into account the equipment structure, production quality and equipment cost at the same time, and achieve simple structure, guaranteed sealing performance, Guarantee the effect of heating function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

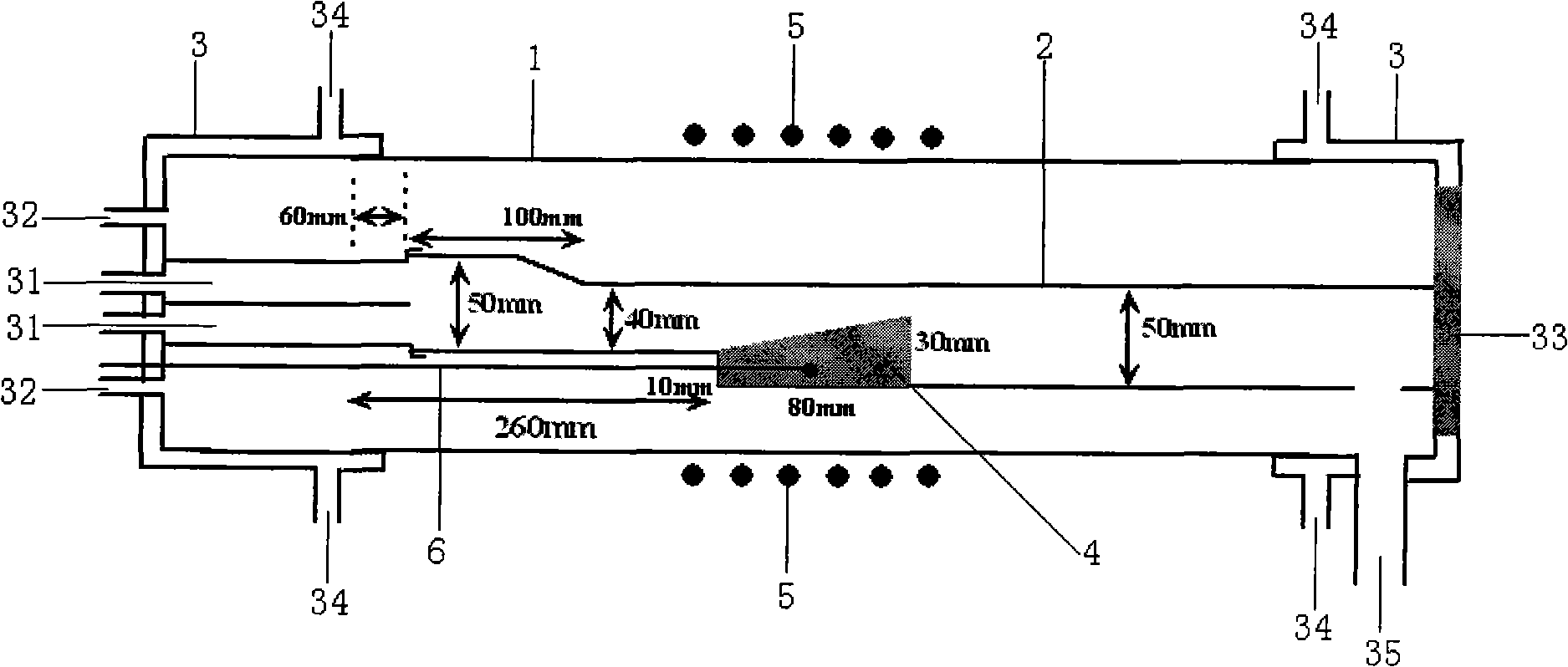

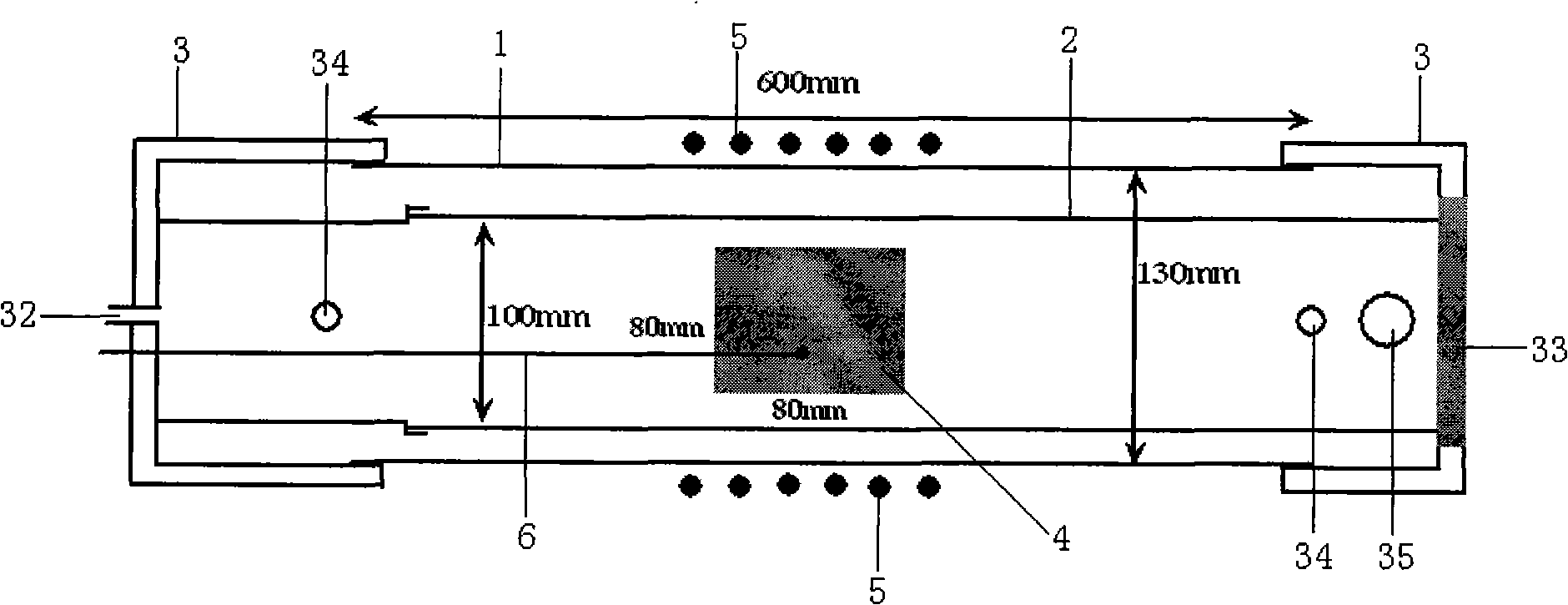

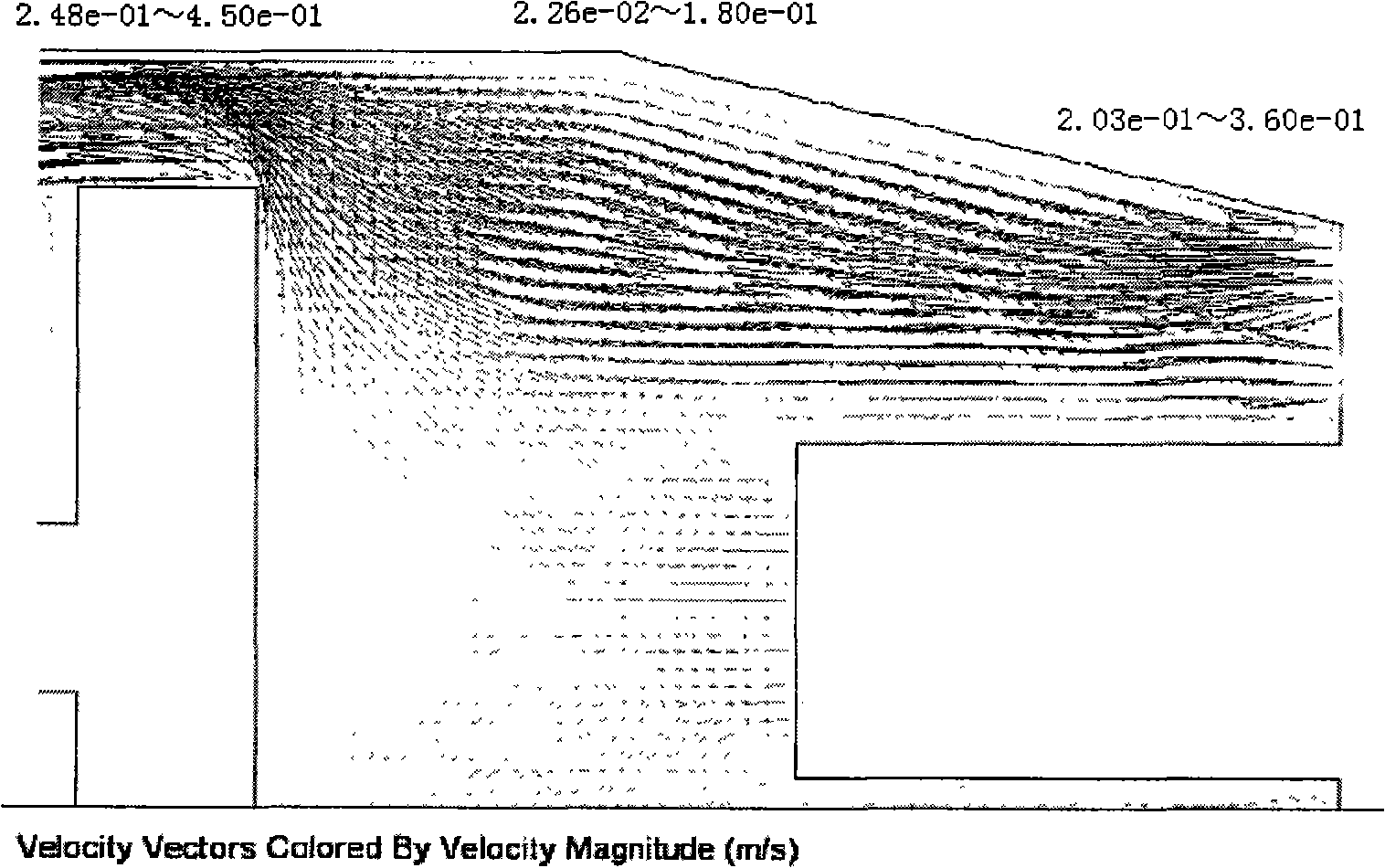

[0016] The specific structure of the device of the present invention is as figure 1 and figure 2As shown, the two ends of the horizontal quartz tube 1 are provided with metal flanges 3, and the metal flanges 3 seal the two ends of the quartz tube 1, and one of the two metal flanges 3 is provided with vertically distributed multi-channel reaction gas inlets 31 and Protective gas inlet 32, one with cover 33 and gas extraction hole 35, reaction gas inlet 31, protective gas inlet 32 and gas extraction hole 35 to ensure the gas circulation of the entire equipment, two metal flanges 3 Both are provided with a cooling water flow port 34 to circulate cooling water to form a water cooling structure; a rectangular quartz fairing 2 and a graphite substrate support 4 are arranged inside the quartz tube 1, and a protective gas inlet is provided between the quartz tube 1 and the quartz fairing 2 32. Pass in protective gas and cleaning balance gas, such as gases such as hydrogen or nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com