Preparation method of holographic grating provided with surface with periodically graded width

A holographic grating and periodic technology, applied in the field of nanomaterials, can solve the problems of complex process, high cost and slow speed, and achieve the effects of large structure area, low production cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

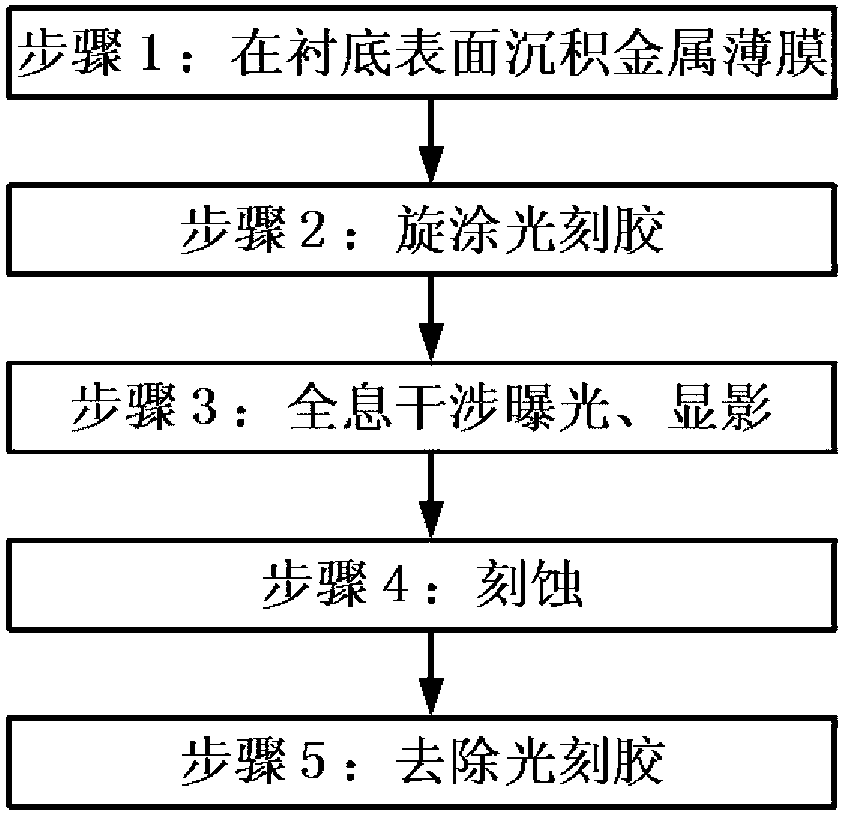

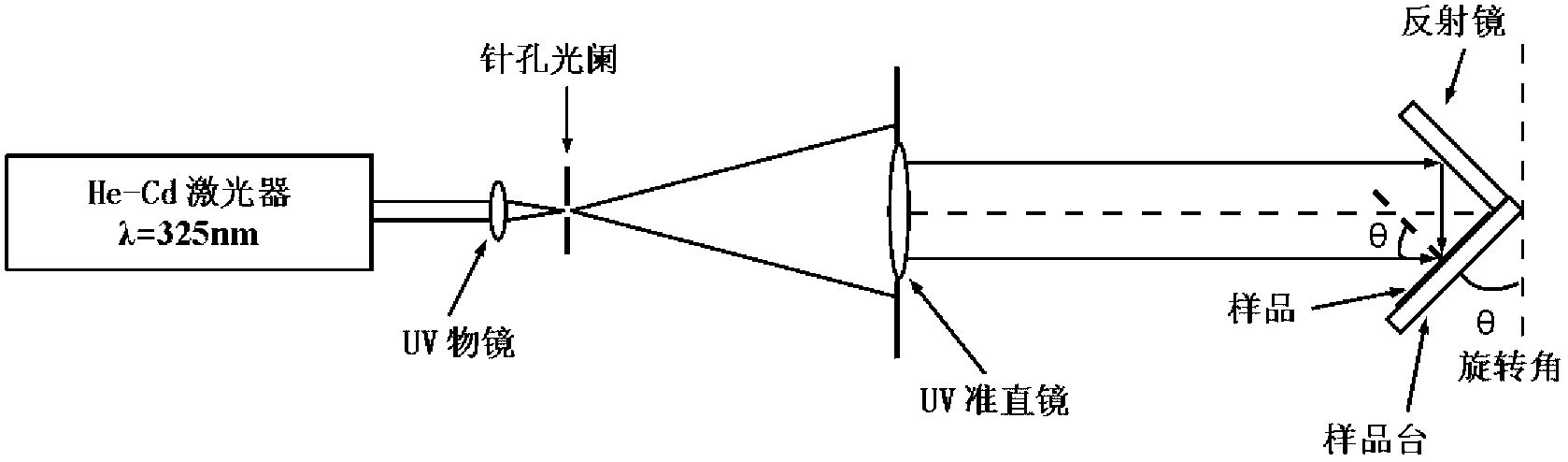

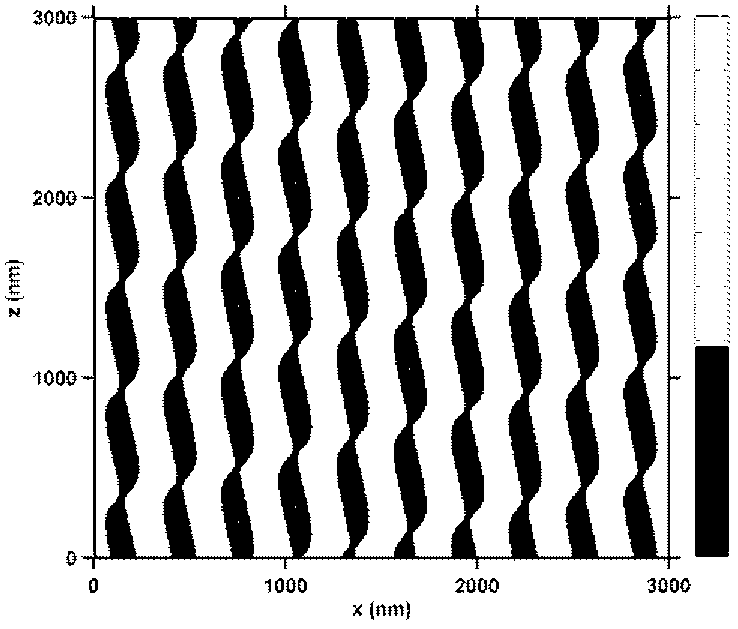

[0024] see figure 1 As shown, the present invention provides a method for preparing a holographic grating with a periodically varying width surface, comprising the following steps:

[0025] Step 1: Take a substrate and clean it to remove surface impurities. Taking a single crystal Si substrate as an example, first scrub the polished surface of the substrate with cotton soaked in acetone; place it in acetone and absolute ethanol in sequence for 5 minutes (temperature 55°C); rinse with deionized water 40 times; Boil it with a mixed solution of sulfuric acid and hydrogen peroxide with a concentration of 4:1 for 10 minutes (add hydrogen peroxide after the sulfuric acid smokes); rinse it with deionized water 40 times; then use a concentration of 3:1:1 deionized water, hydrogen peroxide and The mixed solution of ammonia and water was boiled for 10 minutes (the water was smoking and the other two solutions were added); then rinsed with deionized water for 40 times; finally, it was s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com