Double-carrier ozone catalyst and modular catalytic oxidation waste water treatment device

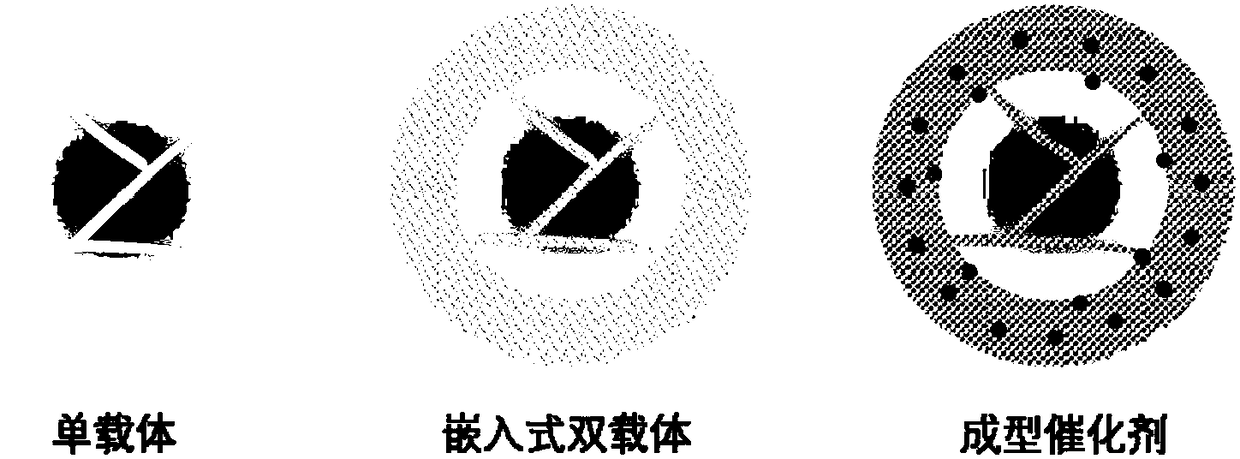

An ozone catalytic oxidation, dual-carrier technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, degassed water/sewage treatment, etc., can solve the problem of short service life of carbon-based catalysts, easy loss of catalytic components, and catalytic performance Reduce problems such as improving stability and catalytic performance, high stability and catalytic performance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

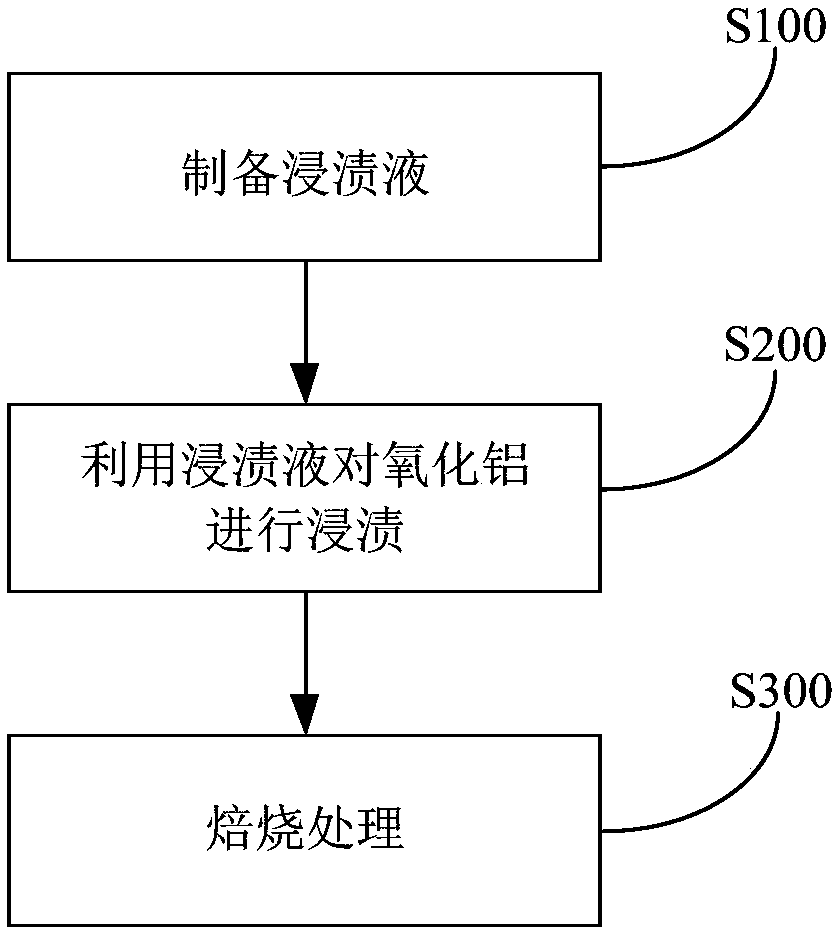

[0106] Follow the steps below to prepare a dual carrier ozone catalyst:

[0107] (1) Select 25 g of γ-alumina particles with a size of 3-5 mm, wash them with deionized water, and dry them at 105° C. for 12 hours.

[0108] (2) Weigh 2.5 g of glucose and 0.5 g of nickel acetate tetrahydrate at room temperature, and add 25 mL of deionized water to prepare the first impregnating solution.

[0109] (3) Weigh 1.3 g of copper acetate monohydrate and 0.4 g of cobalt acetate tetrahydrate at room temperature, and add them into the first impregnating liquid to dissolve completely to obtain the impregnating liquid.

[0110] (4) Vacuum impregnate the weighed γ-alumina in the above impregnation solution. After the impregnation is sufficient, place the impregnated γ-alumina at room temperature for 6 hours to fully diffuse the precursor, and then place it at 65°C Dry and pre-pyrolyze in a vacuum oven.

[0111] (5) Put the above-mentioned dried γ-alumina in a nitrogen-protected furnace at a ...

Embodiment 2

[0113] refer to Figure 10 , through the module switching control system 500 to control the opening and closing of the corresponding solenoid valve 400 to form a series operation mode of the catalytic reaction modules, and at the same time open the cut-off valve 330 of the catalytic reaction module that is determined to participate in the reaction and keep it unblocked. Waste water enters through the water inlet 110 of the waste water pipeline 100, ozone is generated by the ozone generation system 200, mixed with the waste water and enters the catalytic reaction module ①, and then passes through the remaining four catalytic reaction modules ②~⑤, and is separated by the gas-liquid separation system 600 , the liquid phase flows out from the treated wastewater outlet 630 to become effluent, and the gas phase is treated and harmless by the tail gas treatment system 700 and then emptied.

Embodiment 3

[0115] refer to Figure 11 , through the module switching control system 500 to control the opening and closing of the corresponding solenoid valve 400, forming a series operation mode of the catalytic reaction module, and closing the stop valve 330 at both ends of the catalytic reaction module ①, at this time, the catalytic reaction module ① has been separated from the process, The catalyst can be serviced, cleaned or replaced. The remaining four reaction modules operate normally in series.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com