Monolithic integrated non-refrigerated infrared/ultraviolet double-color detector and manufacture method thereof

An uncooled infrared and two-color detector technology, which is applied in the field of photoelectric detectors, can solve the problems of bulky refrigeration systems and the difficulty of realizing low-cost portable system requirements, so as to reduce the size of devices, improve the probability of detection and identification, and reduce processing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

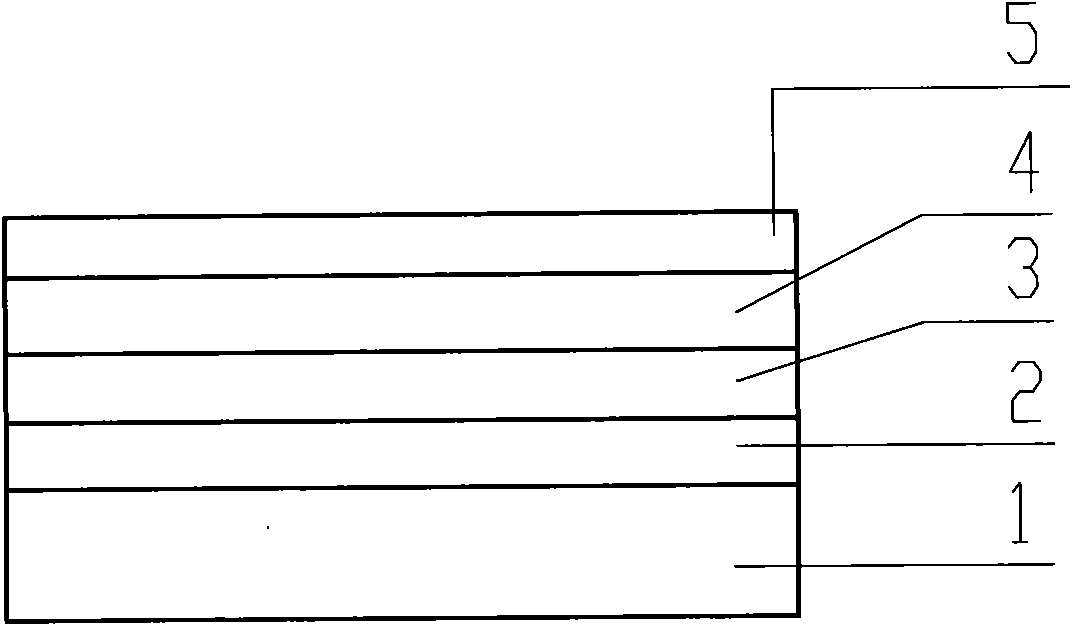

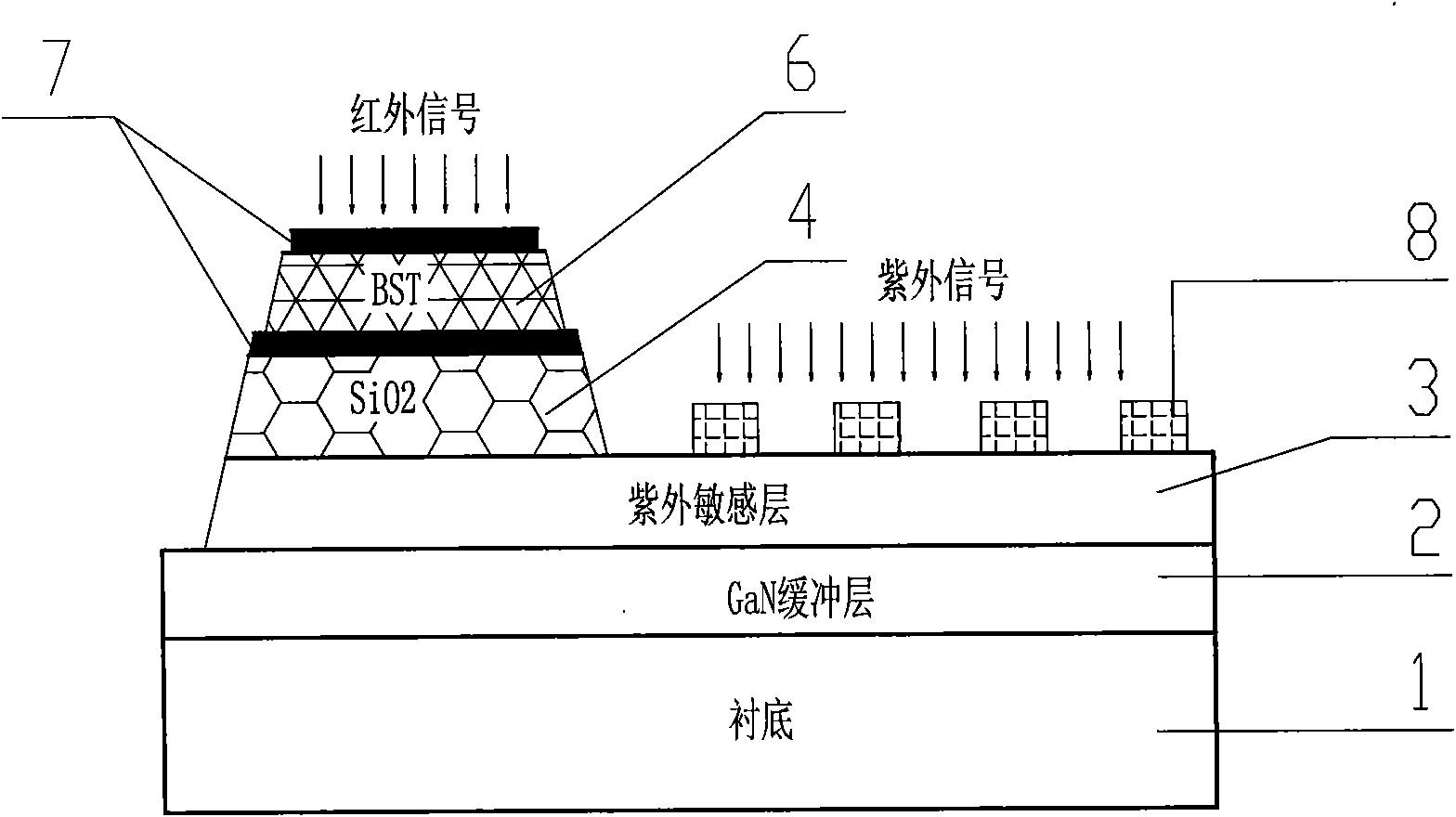

[0020] This embodiment is a specific manufacturing process of a BST / GaN uncooled monolithic integrated infrared / ultraviolet dual-color detector. The infrared / ultraviolet dual-color detector manufactured by using this method and material has the following characteristics: figure 2 For the structure shown, the specific steps are as follows:

[0021] 1) Firstly, the basic material structure is grown, and a 1.5μm GaN buffer layer and a 2μm non-doped GaN ultraviolet absorption layer (Si doping concentration is 1×10) are grown on a sapphire substrate with MOCVD system. 16 cm-3); 2μm porous silica grown by gel sol method and 200nm SiNx grown by PECVD as isolation layer; Pt / Ti deposited by magnetron sputtering system, 30nm Pt / 100nm Ti composite metal film as infrared detection Bottom electrode of the detector; use a magnetron sputtering system to deposit barium strontium titanate (BST) film with a thickness of 500nm and a temperature of 700℃; then use conventional semiconductor photolith...

Embodiment 2

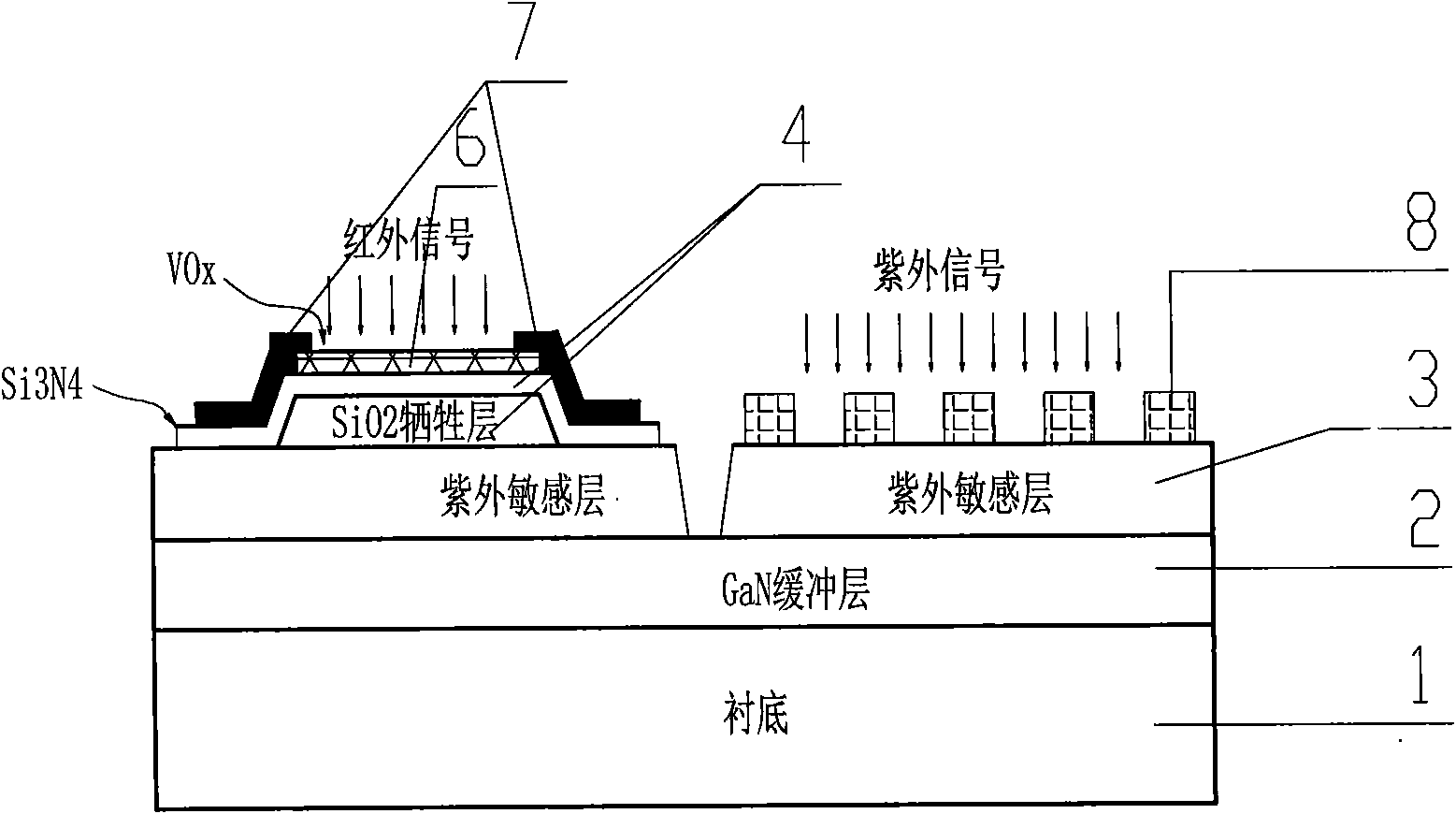

[0031] This embodiment is a specific manufacturing process of a VOx / GaN uncooled monolithic integrated infrared / ultraviolet dual-color detector. The infrared / ultraviolet dual-color detector manufactured by using this method and materials has the following characteristics: image 3 For the structure shown, the specific steps are as follows:

[0032] 1) On a sapphire substrate, a 1.5μm GaN buffer layer and a 2μm non-doped GaN ultraviolet absorption layer (Si doping concentration is 1×10 16 cm-3), such as Figure 5a Shown

[0033] 2) Use PECVD to grow 2.5μm thick porous structure SiO2 as the sacrificial layer, such as Figure 5b Shown

[0034] 3) Photoetch the support leg pattern of the bridge deck, and remove the SiO2 at the support leg position by reactive ion etching, such as Figure 5c Shown

[0035] 4) PECVD growth of 0.5μm Si3N5 bridge support layer, such as Figure 5d Shown

[0036] 5) Use magnetron sputtering to grow 50nm VOx film; use photoresist to mask and etch sensitive el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com