Vertical cavity surface emitting laser and manufacturing method thereof

A technology of vertical cavity surface emission and manufacturing method, which is applied in the field of vertical cavity surface emitting laser and its production, which can solve the problems of AlInP material oxidation, low threshold, and affecting output power, so as to reduce free carrier absorption and reduce difficulty , the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

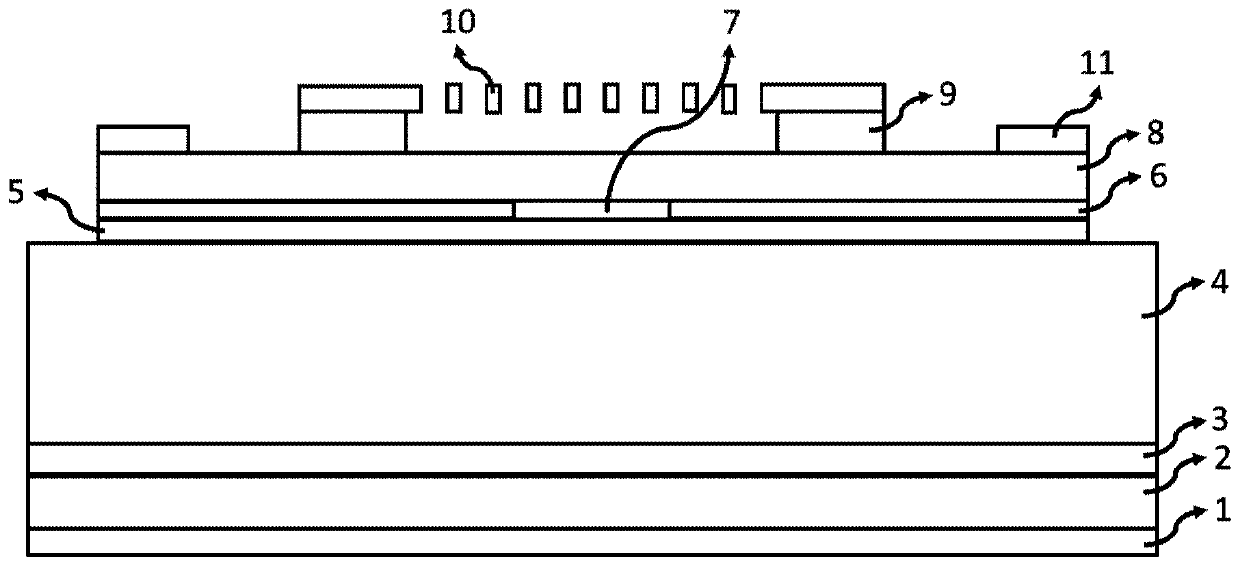

[0070] Embodiment 1 of the present invention provides a vertical cavity surface emitting laser. figure 1 It is a schematic structural diagram of a vertical cavity surface emitting laser according to Embodiment 1 of the present invention; Figure 4 It is a scanning electron microscope image of the suspended GaAs-based HCG layer in Example 1 of the present invention. Such as figure 1 with Figure 4 As shown, the vertical cavity surface emitting laser of the present invention has an operating wavelength of 940nm, including a substrate 2, a buffer layer 3, a lower DBR4, an active layer 5, a current confinement layer 6, a current confinement aperture 7, and a current diffusion layer 8. GaInP sacrificial layer 9 , non-doped suspension type GaAs-based HCG layer 10 , n-side electrode 1 and p-side electrode 11 .

[0071] Substrate 2 is an n-type GaAs substrate.

[0072] The buffer layer 3 is n-type GaAs.

[0073] Lower DBR4 is n-type Al 0.12 Ga 0.88 As / Al 0.9 Ga 0.1 As is DBR....

Embodiment 2

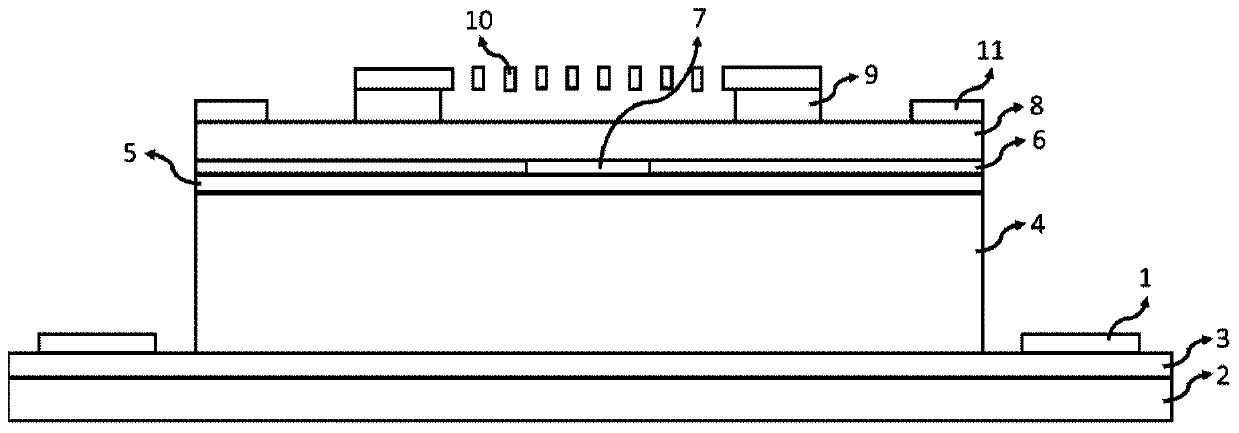

[0092] Embodiment 2 of the present invention provides a vertical cavity surface emitting laser, figure 2 It is a schematic structural diagram of a vertical cavity surface emitting laser according to Embodiment 2 of the present invention; Figure 4 It is a scanning electron microscope image of the suspended GaAs-based HCG layer in Example 2 of the present invention. Such as figure 2 with Figure 4 As shown, the vertical cavity surface emitting laser of the present invention has an operating wavelength of 980nm, including a substrate 2, a buffer layer 3, a lower DBR4, an active layer 5, a current confinement layer 6, a current confinement aperture 7, and a current diffusion layer 8, GaInP sacrificial layer 9 , non-doped suspension type GaAs-based HCG layer 10 , n-side electrode 1 , and p-side electrode 11 .

[0093] Substrate 2 is an n-type GaAs substrate.

[0094] The buffer layer 3 is n-type GaAs.

[0095] Lower DBR4 is n-type Al 0.12 Ga 0.88 As / Al 0.9 Ga 0.1 As is ...

Embodiment 3

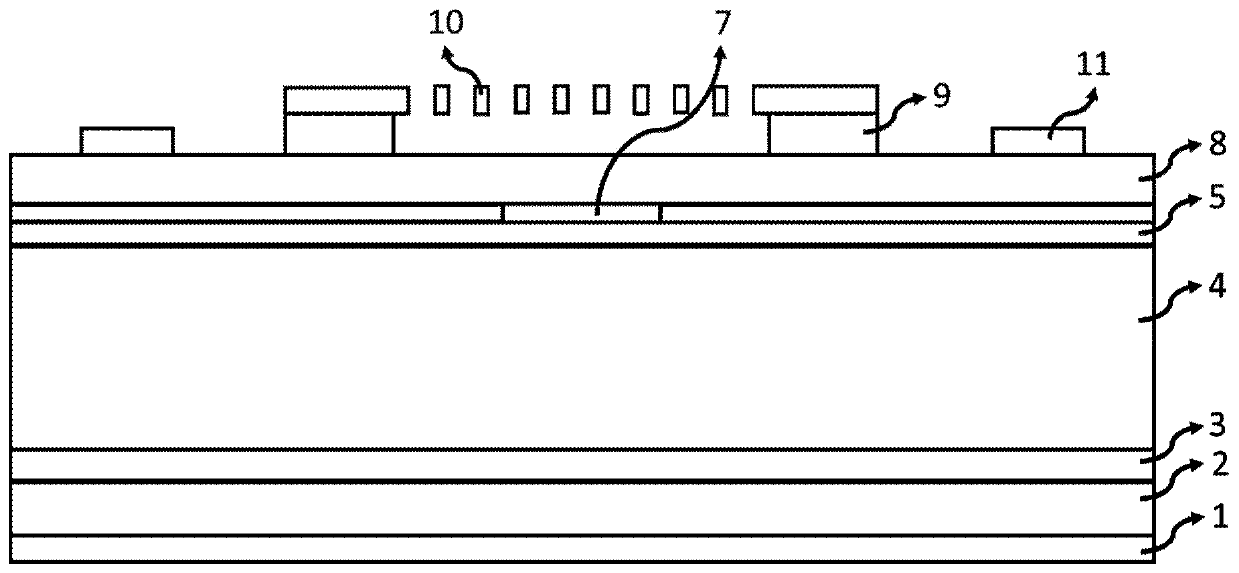

[0115] Embodiment 3 of the present invention provides a vertical cavity surface emitting laser, image 3 It is a schematic structural diagram of a vertical cavity surface emitting laser according to Embodiment 3 of the present invention. Such as image 3 As shown, the vertical cavity surface emitting laser of the present invention has an operating wavelength of 1550nm, including a substrate 2, a buffer layer 3, a lower DBR4, an active layer 5, a current confinement aperture 7, a current diffusion layer 8, and an InGaAs sacrificial layer 9, Non-doped suspension type InP-based HCG layer 10 , n-side electrode 1 , and p-side electrode 11 .

[0116] Substrate 2 is an n-type InP substrate.

[0117] The buffer layer 3 is n-type InP.

[0118] The lower DBR4 is an n-type InGaAlAs / InAlAs-based DBR.

[0119] The active layer 5 is three InGaAlAs quantum wells.

[0120] The current confining aperture 7 consists of a tunnel structure.

[0121] The current spreading layer 8 is n-type I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com