Enhanced AlGaN/GaN field effect tube and manufacturing method thereof

A fabrication method and technology for field effect transistors, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as deteriorating device performance and reliability, and achieve a simple and reliable implementation method, reduce complexity, and reduce sources of energy. The effect of leakage access resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

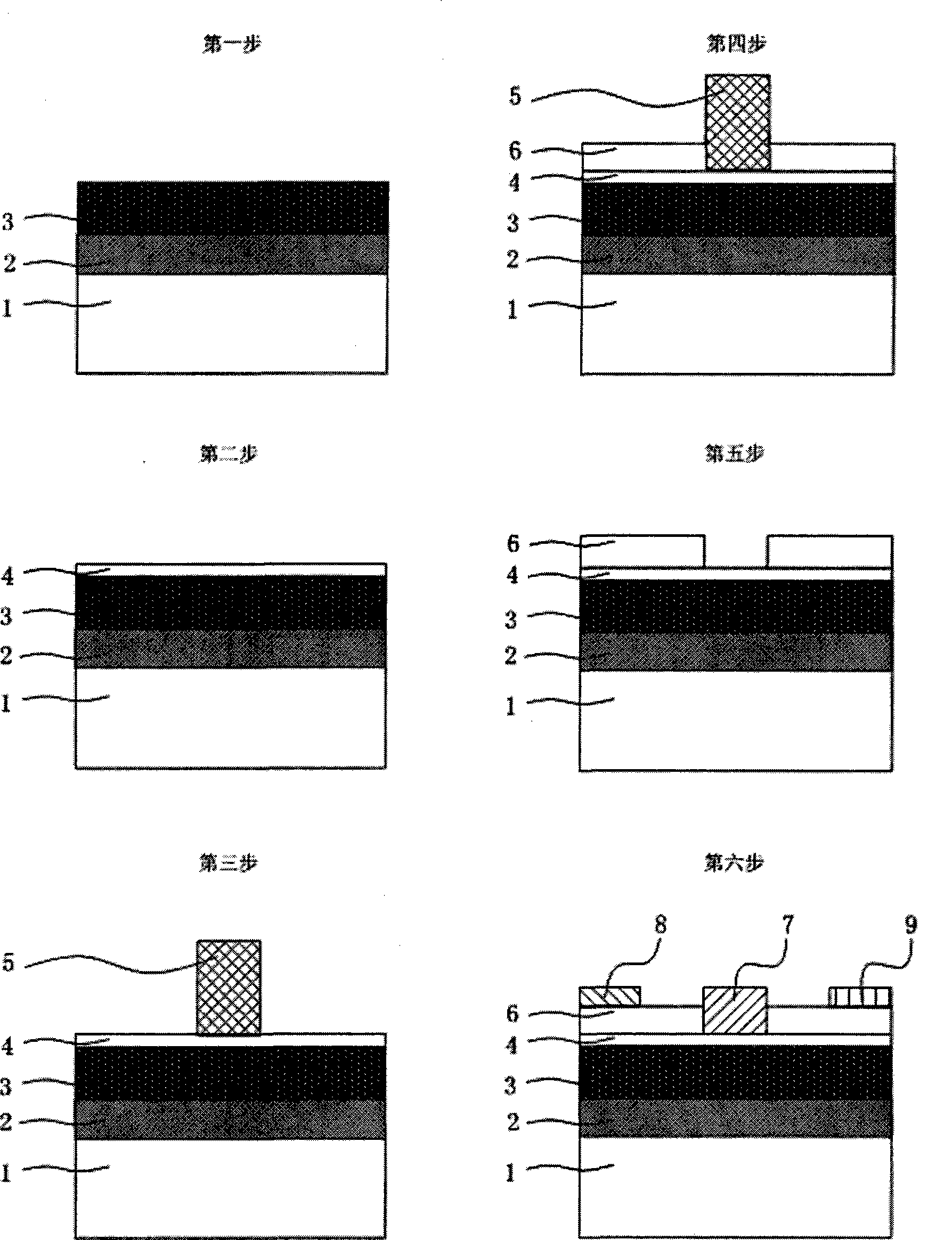

[0033] Such as image 3 As shown, the present invention provides a method for manufacturing an enhanced AlGaN / GaN field effect transistor, which includes the following steps:

[0034] Step 1: Using a 300 μm thick sapphire (Sapphire) substrate 1, using the MOCVD method, at a temperature of 1100 ° C, hydrogen and ammonia as protective gases, first grow a 20 nm thick AlN buffer layer 2, and then control the growth conditions A high-resistance GaN layer 3 with a thickness of 3 μm is grown thereon.

[0035] Step 2: Using the MOCVD method to maintain a growth temperature of about 1100° C., and controlling the flows of the aluminum source and the gallium source fed into the reaction chamber, grow an AlGaN thin layer 4 with a thickness of 5-10 nm. The AlGaN layer and the GaN layer 3 have different compositions. A low-concentration two-dimensional electron gas is formed at the interface.

[0036] Step 3: On the AlGaN thin layer 4 with a thickness of 5-10nm, first deposit SiO with a t...

Embodiment 2

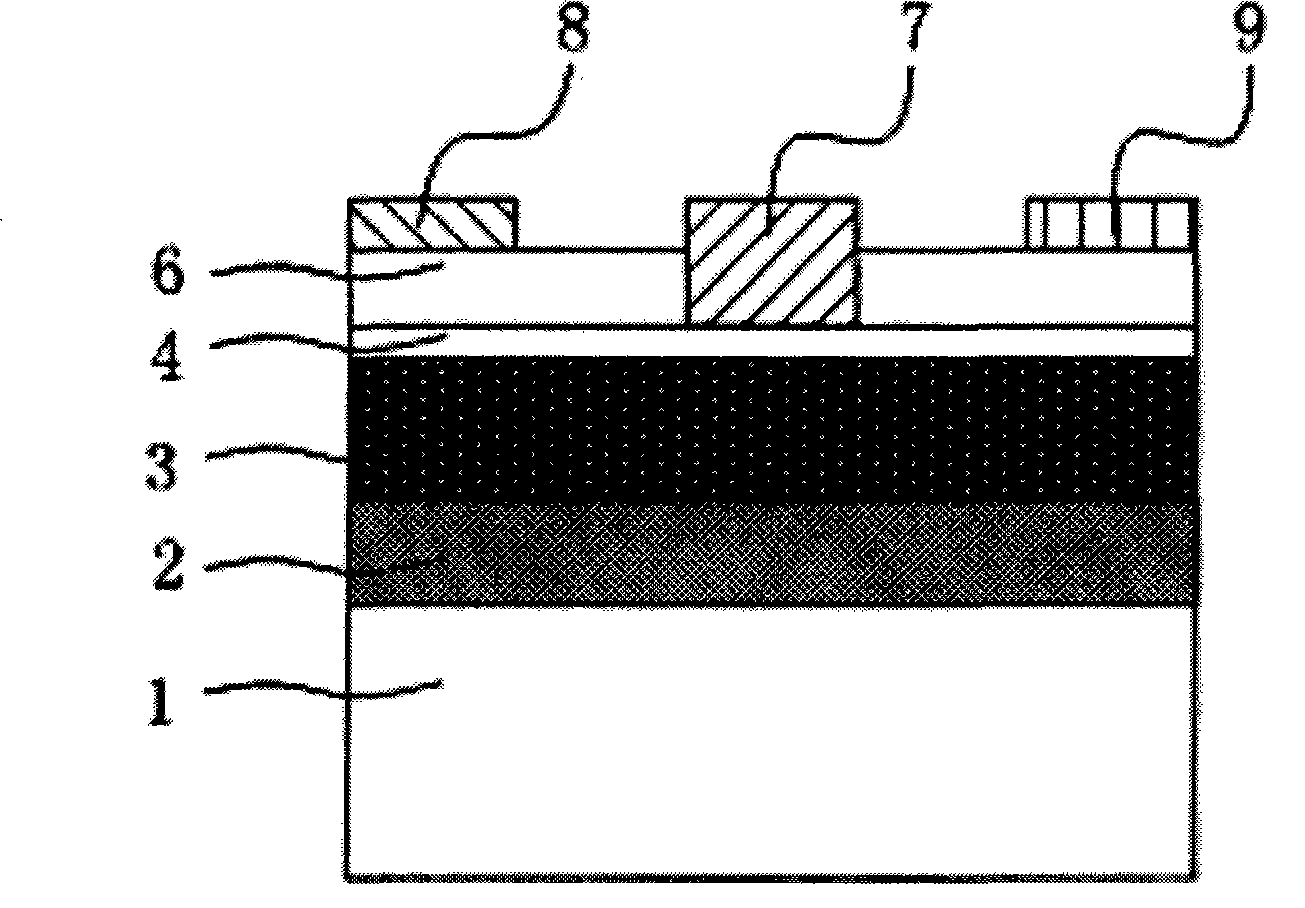

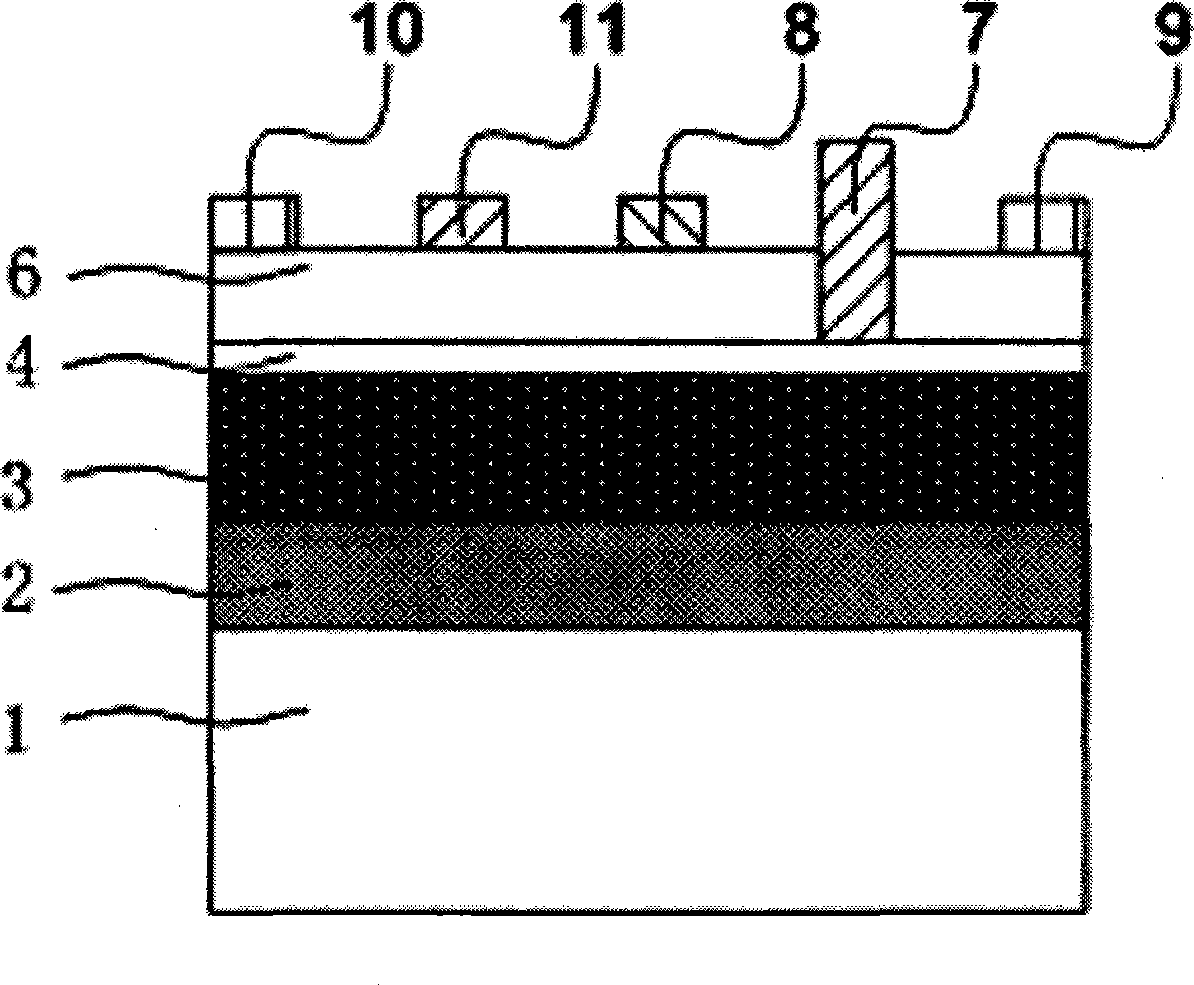

[0045] Such as figure 2 As shown, this embodiment adopts the same steps as Step 1 to Step 6 in Embodiment 1. Then, on the secondary grown second AlGaN layer 6 , continue to use the vapor deposition method to form the Ti / Al / Ni / Au second drain 10 first, and then form the Ni / Au second gate 11 . In this way, the gate electrode 7 on the first AlGaN layer 4 grown once and the source electrode 8 and drain electrode 9 on the second AlGaN layer 6 grown secondarily constitute a local enhanced AlGaN / GaN HFET structure; On the grown second AlGaN layer 6, a local depletion-type AlGaN / GaN HFET structure is formed by the source 8, the drain 10, and the gate 11, thereby forming a composite AlGaN / GaN HFET in which enhancement and depletion coexist. structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com