Modified technique for refined unit in acrylic acid production device

A production device and acrylic acid technology are applied in the field of improvement of refining units in acrylic acid production devices, which can solve the problems affecting the long-term stable operation of the device, high processing costs, and difficult operation, and achieve obvious economic and social benefits, saving Device operating cost and the effect of significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

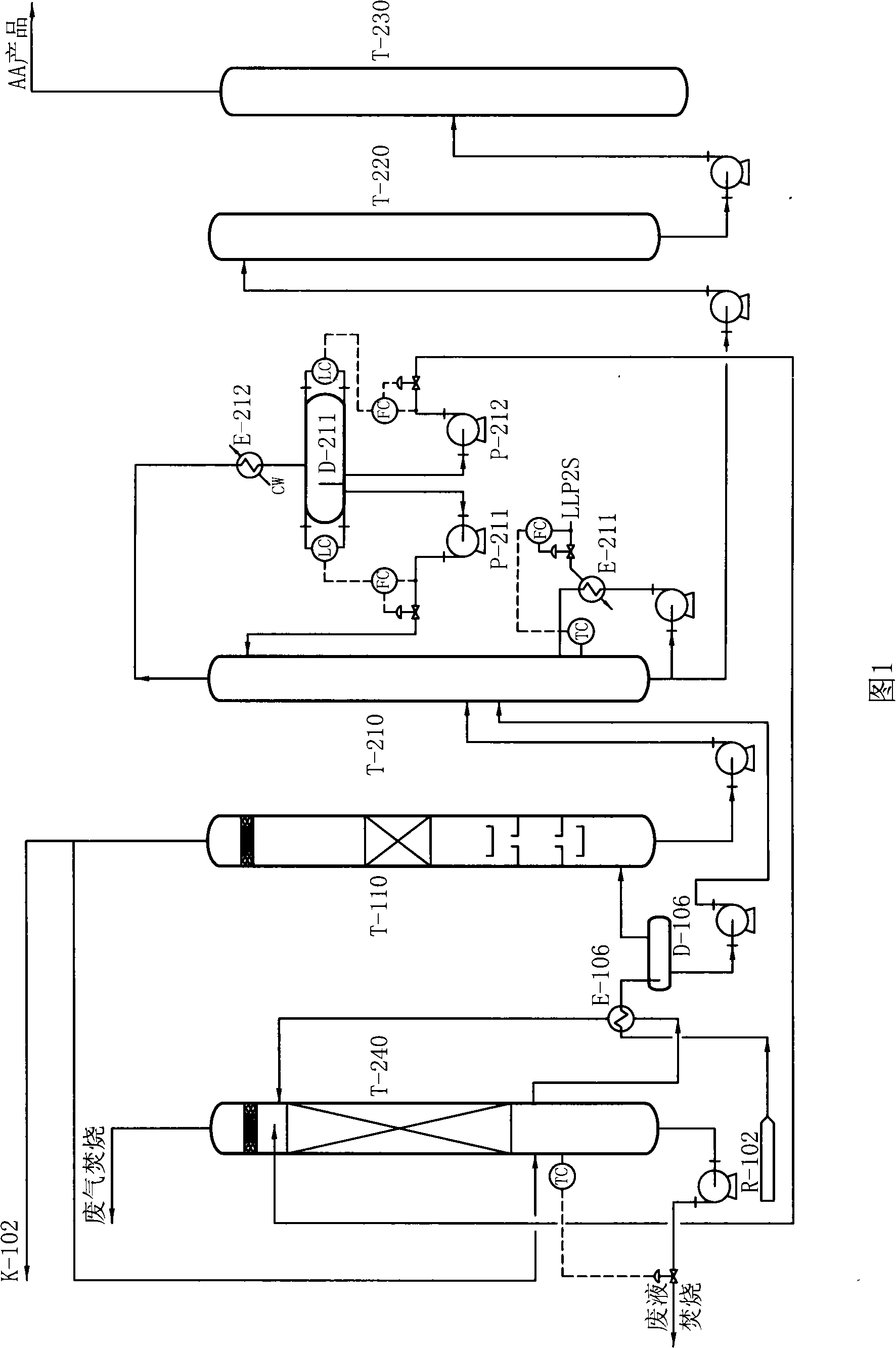

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The acrylic acid gas generated by the second acrylic acid reactor R-102 reaches 67°C after heat exchange between the reactant cooler E-106 and the circulating wastewater of the waste water stripping tower, and the gas enters the absorption tower after being separated by the gas-liquid separation tank D-106 T-110 cools and absorbs, the lower liquid directly enters the light component fractionation tower T-210, and the crude acrylic acid solution at the bottom of T-110 is sent to the acrylic acid refining unit. A part of the unabsorbed gas at the top of the tower is compressed by the circulating compressor and circulated to the mixer for reaction. The rest is sent to the bottom of stripper T-240.

[0026] The crude acrylic acid aqueous solution at the bottom of the T-110 tower is pumped to the middle of the light component fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com