Catalyzing cracking slurry oil topping tech. and industry apparatus thereof

A technology of catalytic cracking oil slurry and process equipment, which is applied in the field of catalytic cracking oil slurry topping process and industrial equipment, which can solve the problems of reducing wax content, high wax content, low flash point, etc., and achieves flexible operation and wide adaptability of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

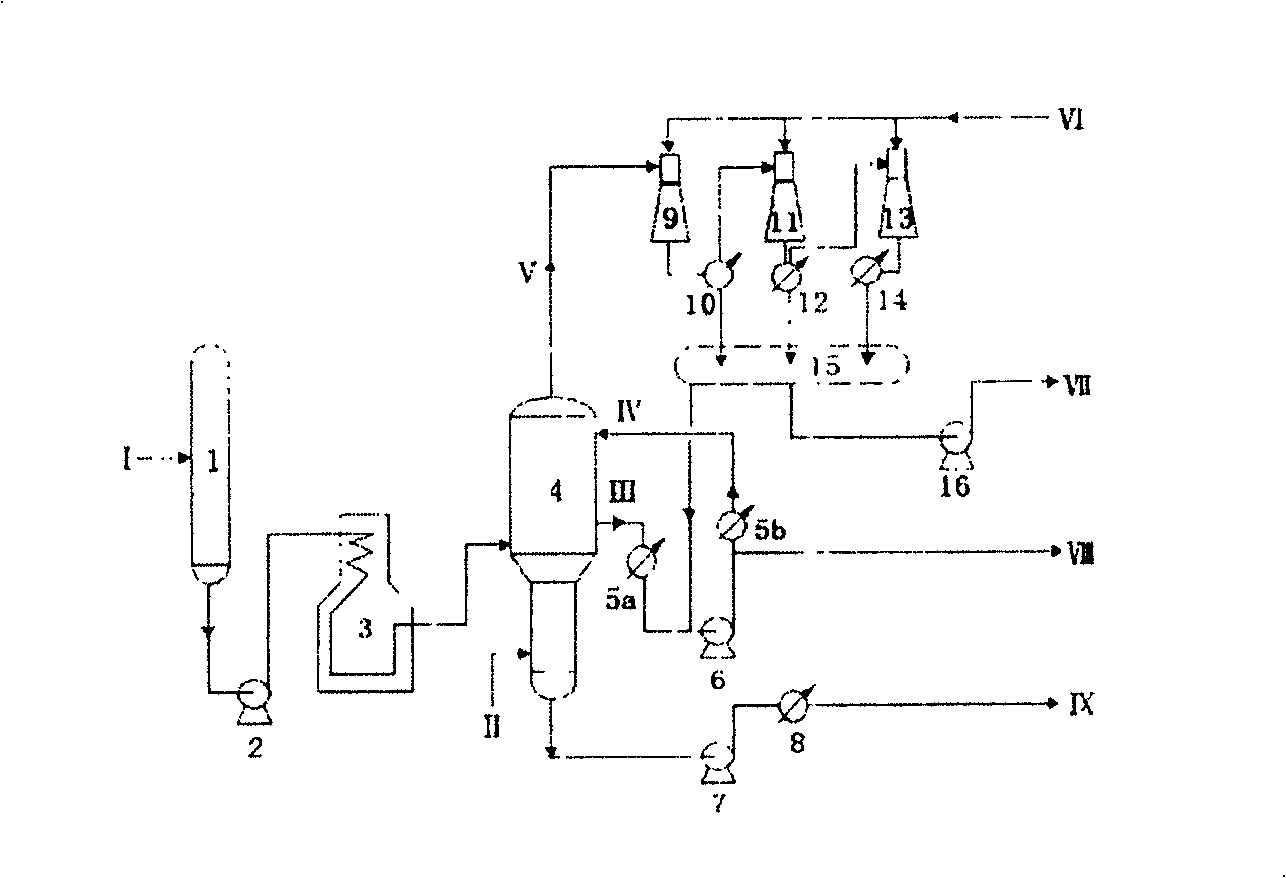

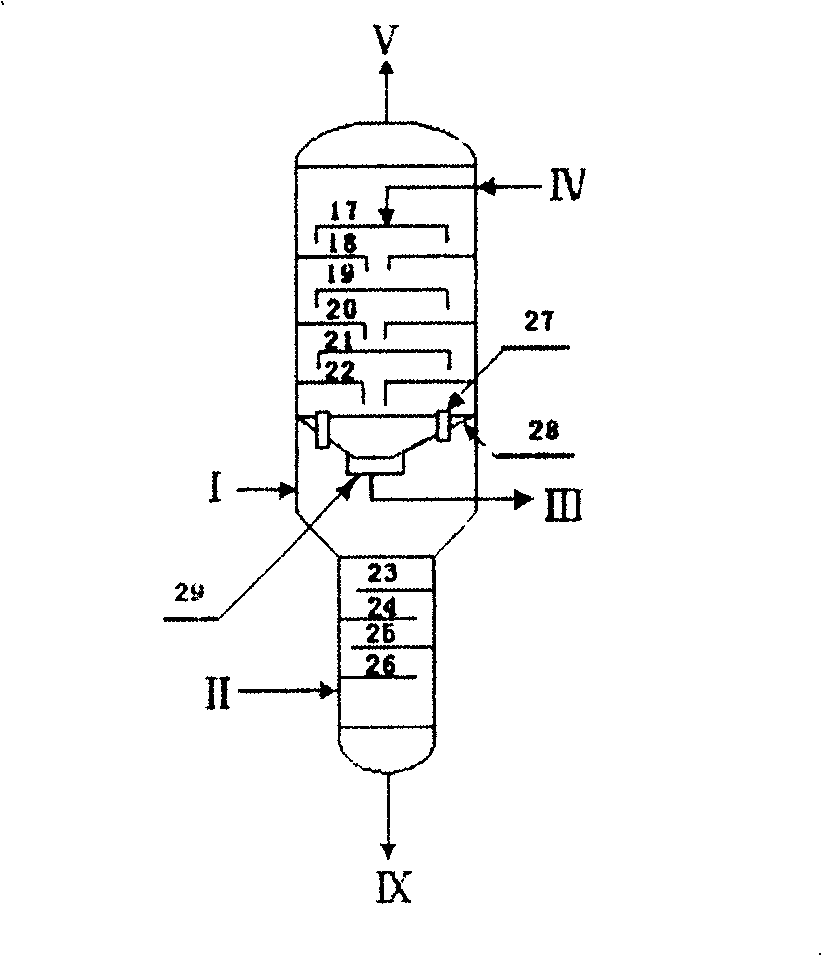

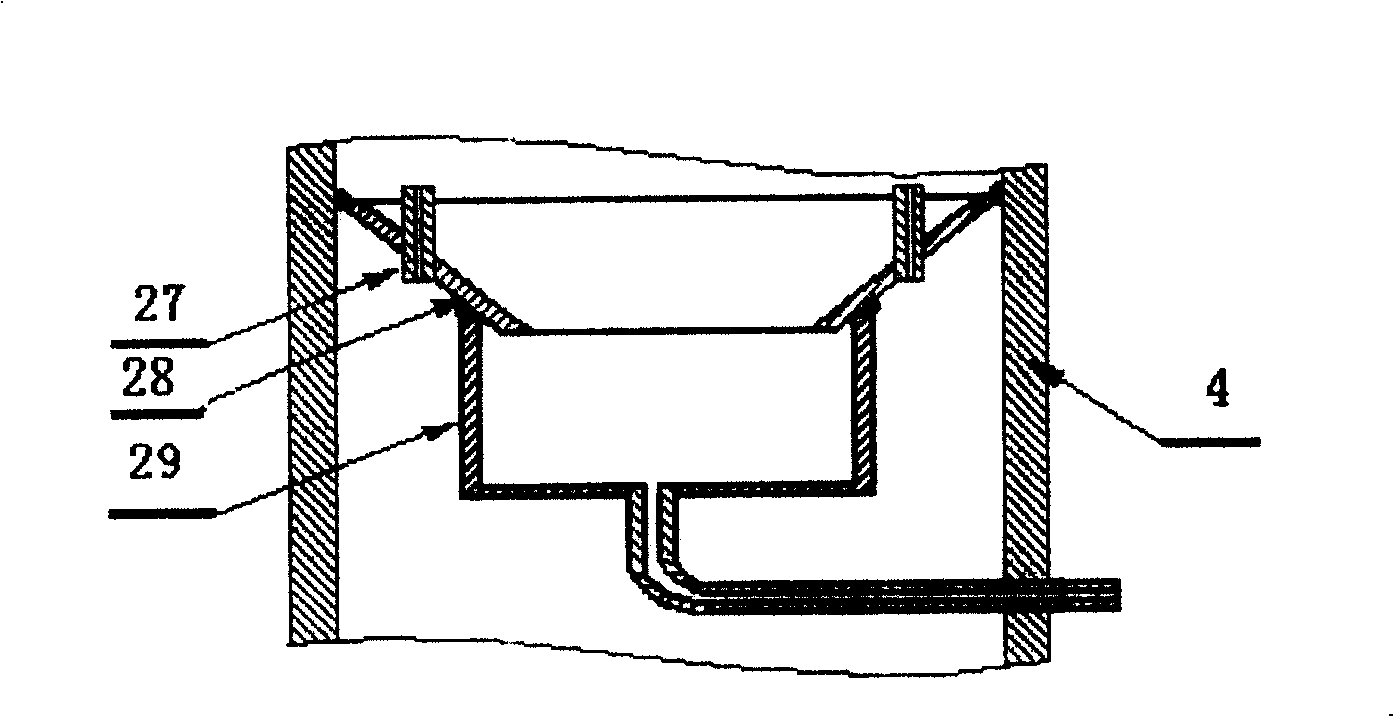

Method used

Image

Examples

Embodiment 1

[0028] The catalytic cracking oil slurry topping process proposed in this embodiment is: the catalytic cracking oil slurry I is heated to 350 ° C and then continuously enters the oil slurry topping tower. Under the operating pressure of 0.5Kpa, it is vaporized and separated into light and heavy. Components, the light components are all extracted from the light oil slurry collector located between the rectification section and the stripping section, part of which is used as raw material for visbreaking, delayed coking or thermal cracking devices after primary cooling, and the other part is used for secondary After being cooled to 70 DEG C, return the oil slurry head tower from the top of the rectifying section as the cold reflux at the top of the tower; After the hot water steam is stripped, it is drawn from the bottom of the tower, cooled to 90°C by the heavy oil slurry cooler 8, and then sent to the asphalt blending facility to blend soft components.

[0029] In this embodime...

Embodiment 2

[0034] The catalytic cracking oil slurry topping process proposed in this embodiment is: the catalytic cracking oil slurry I is heated to 324 ° C and then continuously enters the oil slurry topping tower. Under the operating pressure of 2.0Kpa, it is separated into light and heavy after vaporization. Components, the light components are all extracted from the light oil slurry collector located between the rectification section and the stripping section, part of which is used as raw material for visbreaking, delayed coking or thermal cracking devices after primary cooling, and the other part is used for secondary After being cooled to 95°C, return the oil slurry head tower from the upper part of the rectification section as a cold reflux at the top of the tower; the superheated stripping steam consumption of the heavy component in the stripping section is 1.8% (weight) superheat of the oil slurry feed amount After steam stripping, it is drawn from the bottom of the tower, cooled...

Embodiment 3

[0037] The catalytic cracking oil slurry topping process proposed in this embodiment is: the catalytic cracking oil slurry I is heated to 290 ° C and then continuously enters the oil slurry topping tower. Under the operating pressure of 3.0Kpa, it is separated into light and heavy after vaporization. Components, the light components are all extracted from the light oil slurry collector located between the rectification section and the stripping section, part of which is used as raw material for visbreaking, delayed coking or thermal cracking devices after primary cooling, and the other part is used for secondary After cooling to 110°C, return the oil slurry topping tower from the upper part of the rectification section as a cold reflux at the top of the tower; the superheated stripping steam consumption of the heavy component in the stripping section is 1% (weight) superheat of the oil slurry feed amount After steam stripping, it is taken out from the bottom of the tower, coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com