Preparation method of animal compound amino acid injection

A compound amino acid and injection technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc., and can solve problems such as poor stability of amino acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of embodiment 1 livestock compound amino acid injection

[0038] The present embodiment is the preparation method of animal compound amino acid injection, with 1m 3 Taking compound injection for livestock as an example, its specific preparation method includes the following steps carried out in sequence:

[0039] Step 1) Prepare base fluid:

[0040] Take 1000L water for injection, boil and sterilize for 40 minutes, and set aside;

[0041] Take by weighing 0.89kg sodium bisulfite and 0.10kg edetate disodium, set aside;

[0042] Take 600L of water for injection and place it in the concentrated preparation tank, and inject CO 2 Air flow, while controlling the water temperature at 95°C, in CO 2 Add 0.89 kg of disodium ethylenediamine tetraacetate and 0.10 kg of sodium bisulfite under the protection of air flow, stir to dissolve completely, and prepare base liquid A.

[0043] Among them, sodium bisulfite has the effect of preventing the oxidation ...

Embodiment 2~6

[0062] The preparation method of embodiment 2~6 livestock compound amino acid injection

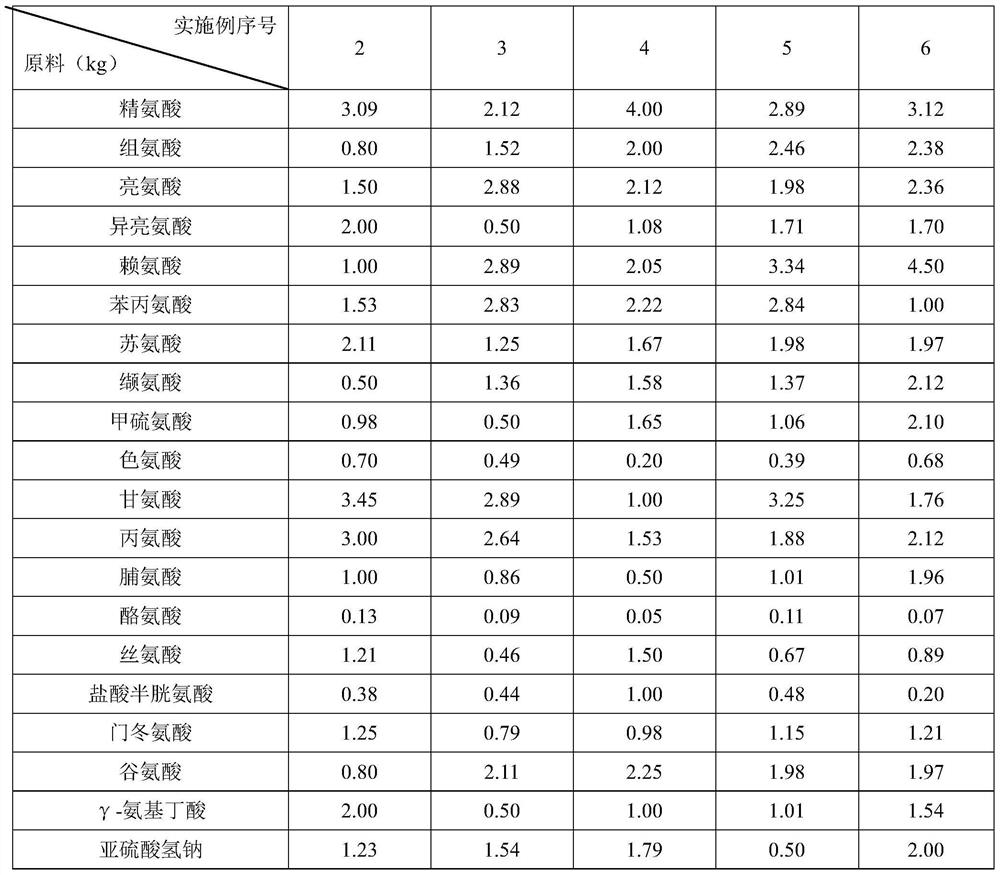

[0063] Examples 2-6 are respectively a preparation method of a compound amino acid injection for livestock, which is basically the same as the preparation method in Example 1, except that the amount of each amino acid raw material and the parameters in each step are different. Taking 1000L compound injection for livestock as an example, the consumption of making its specific active ingredient raw materials is weighed according to the consumption of each active ingredient raw material provided in Table 1 respectively, and the specific active ingredient raw materials are shown in Table 1; Each process parameter in the step, concrete parameter sees table 2:

[0064] Table 1 The dosage list of each active ingredient raw material

[0065]

[0066]

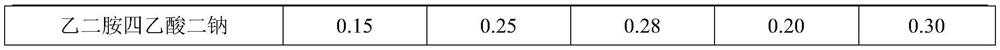

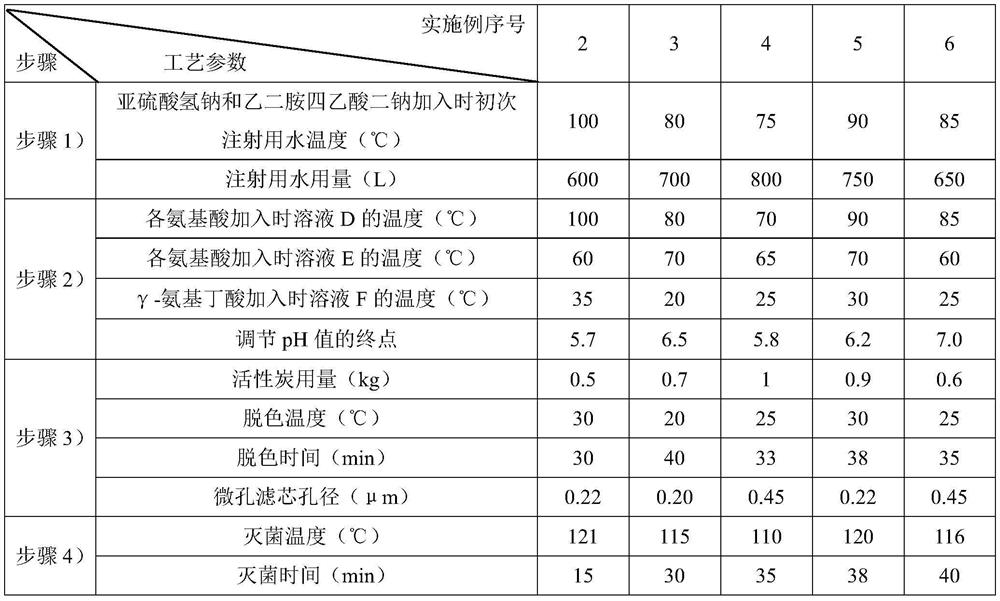

[0067] The list of each process parameter of table 2 embodiment 2~6

[0068]

[0069] The specific situation of each amino acid content...

Embodiment 7

[0075] The quality detection of embodiment 7 compound amino acid injections for livestock

[0076] In this example, the compound amino acid injection for animals prepared by the method in Example 1 was used for quality inspection. The specific detection method is as follows:

[0077] The accelerated test is placed under the conditions of temperature 40±2°C and relative humidity 75±5% for 6 months, and samples are taken at the end of the 0th month, 1st month, 2nd month, 3rd month and 6th month during the test period. The quality standards of WS1~(X~324)~2003Z of "Drug Standards of the State Food and Drug Administration" were tested, and the specific test results are shown in Table 4:

[0078] Table 4 Quality inspection results of compound amino acid injection for livestock

[0079]

[0080]

[0081] As can be seen from Table 4, the animal compound amino acid injection prepared in Example 1 is through the accelerated test, and each index has no obvious change, and the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com